MNO, a negative electrode material for sodium ion batteries x preparation method

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult large-scale factory production, expensive graphene raw materials, complicated preparation process, etc., to achieve the benefit of embedding The effects of detachment, increased active specific surface area, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) getting manganese acetate and ammonium persulfate to be mixed with the manganese acetate solution of 0.12% and the ammonium persulfate solution of 0.11% in mass fraction respectively;

[0026] 2) Disperse the sodium lauryl sulfate in the manganese acetate solution, and magnetically stir until it is completely dissolved to prepare a mixed solution with a mass fraction of sodium lauryl sulfate of 1.96%;

[0027] 3) Take 60ml of ammonium persulfate solution and add it dropwise into 100ml of the mixed solution with a burette, and stir for 2 hours until the system is uniform;

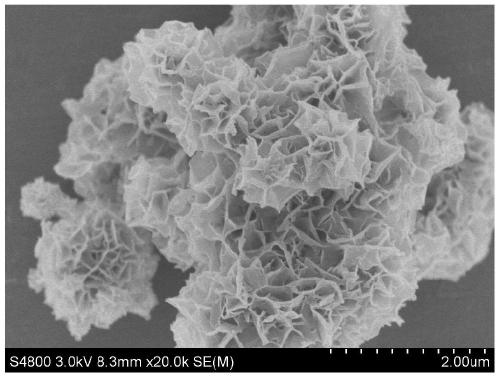

[0028] 4) Move the homogeneously dissolved system to an ultrasonic cleaning machine with a power of 40W for ultrasonic treatment for 3 hours until a black precipitate is produced;

[0029] 5) The black precipitate obtained in step 4) is alternately washed with water and acetone, filtered, and dried to obtain MnOx, a negative electrode material for a sodium ion battery.

Embodiment 2

[0031] 1) getting manganese acetate and ammonium persulfate to be mixed with the manganese acetate solution that is 0.56% and the ammonium persulfate solution that massfraction is 0.75% respectively;

[0032] 2) Sodium lauryl sulfate is dispersed in the manganese acetate solution, and magnetically stirred until it is completely dissolved to prepare a mixed solution with a mass fraction of sodium lauryl sulfate of 3.5%;

[0033] 3) Take 60ml of ammonium persulfate solution and add it dropwise into 50ml of the mixed solution with a burette, and stir for 2 hours until the system is uniform;

[0034] 4) Move the homogeneously dissolved system to an ultrasonic cleaning machine with a power of 90W for ultrasonic treatment for 2 hours until a black precipitate is produced;

[0035] 5) The black precipitate obtained in step 4) is alternately washed with water and acetone, filtered, and dried to obtain MnOx, a negative electrode material for a sodium ion battery.

Embodiment 3

[0037] 1) get manganese acetate and ammonium persulfate to be mixed with respectively the manganese acetate solution that mass fraction is 2.01% and the ammonium persulfate solution that mass fraction is 1.22%;

[0038] 2) Sodium lauryl sulfate is dispersed in the manganese acetate solution, and magnetically stirred until it is completely dissolved to prepare a mixed solution with a mass fraction of sodium lauryl sulfate of 5.5%;

[0039] 3) Take 60ml of ammonium persulfate solution and add it dropwise into 80ml of the mixed solution with a burette, and stir for 4 hours until the system is uniform;

[0040] 4) Move the homogeneously dissolved system to an ultrasonic cleaning machine with a power of 60W for ultrasonic treatment for 4 hours until a black precipitate is produced;

[0041] 5) The black precipitate obtained in step 4) is alternately washed with water and acetone, filtered, and dried to obtain MnOx, a negative electrode material for a sodium ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com