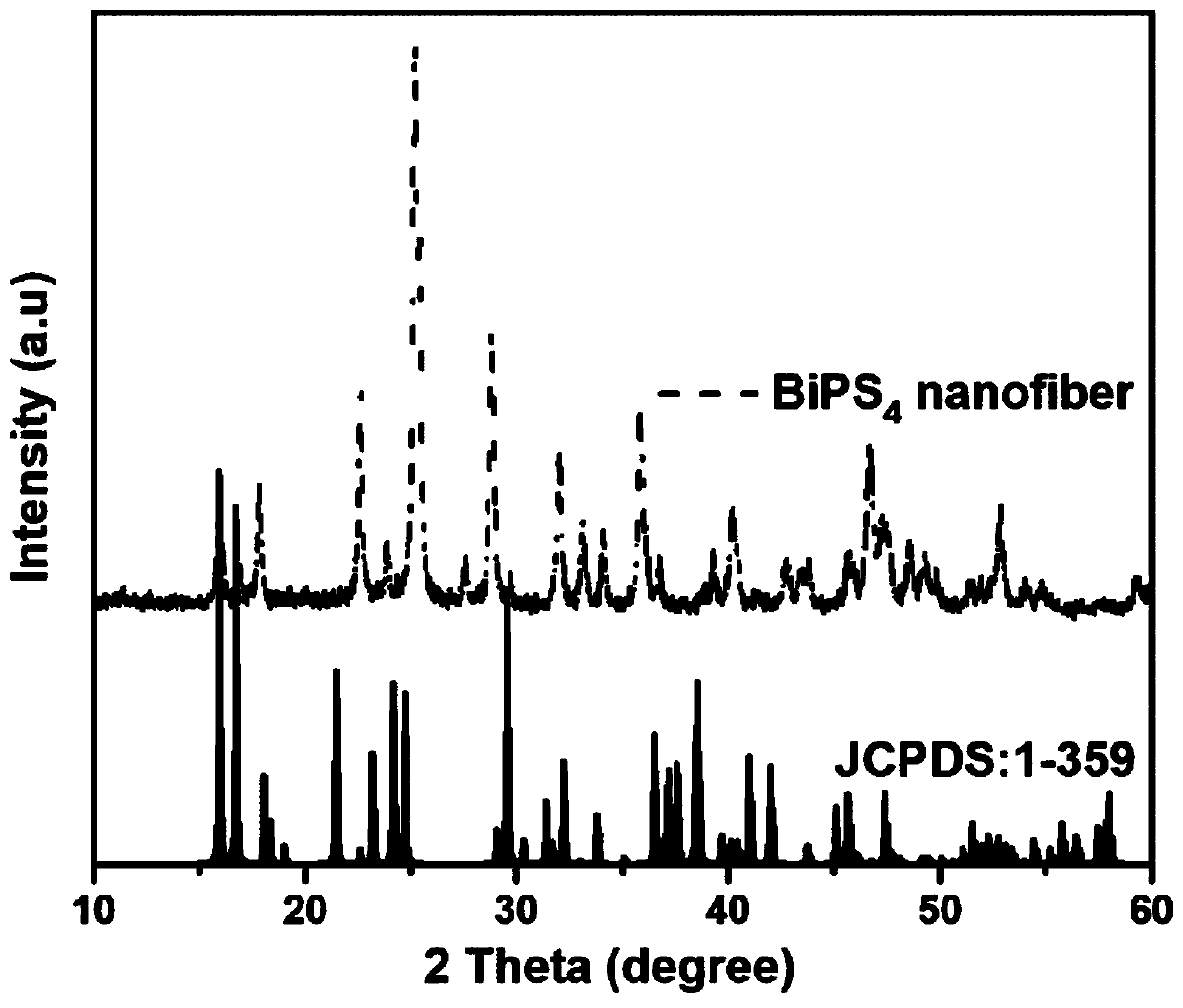

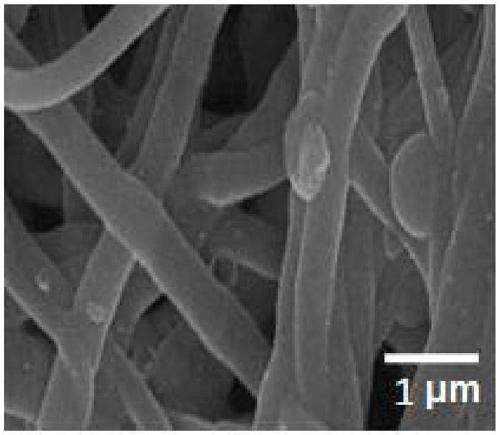

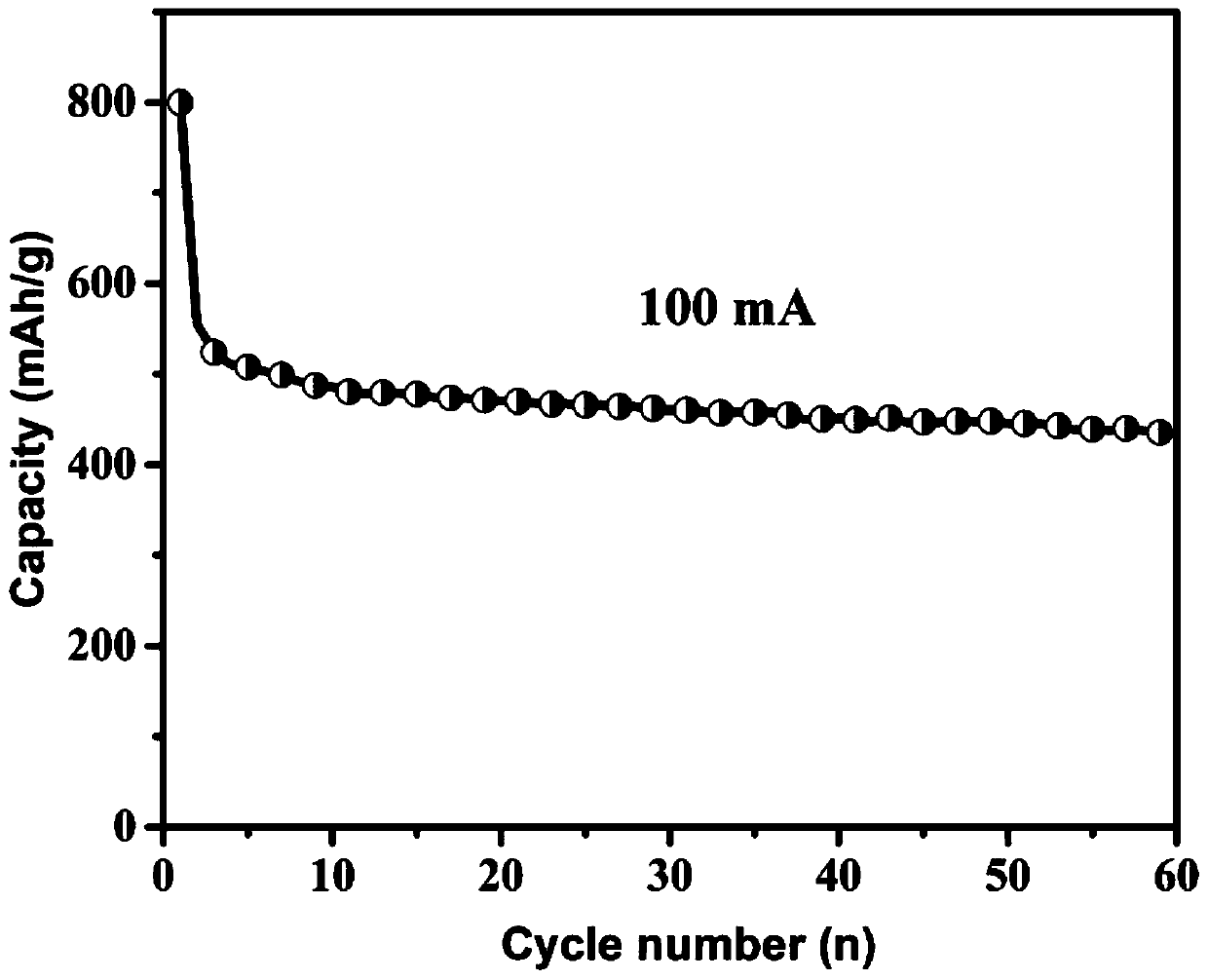

Bismuth phosphorus sulfur/carbon composite nanofiber negative electrode material for sodium-ion battery, preparation method of bismuth phosphorus sulfur/carbon composite nanofiber negative electrode material and sodium-ion battery

A sodium-ion battery and nanofiber technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problem of low specific capacity of negative electrode materials, achieve large specific surface area, increase capacity, and improve Effect of Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material for sodium ion battery of the present embodiment comprises the following steps:

[0037] 1) Add 1.0 g of polyacrylonitrile (PAN) and 0.8 g of bismuth chloride into 10 mL of N,N-dimethylformamide (DMF), then stir overnight at 60 °C to obtain a transparent viscous electrospun silk liquid;

[0038] 2) Add the electrospinning solution obtained in step 1) into the syringe of the electrospinning device, set the distance between the syringe and the aluminum foil receiver to be 18cm, and the voltage of the applied high-voltage electrostatic field is 20kV, and then use 1mL / h The propulsion speed injection, electrospinning;

[0039] 3) Calcining the filaments obtained by electrospinning in step 2) at 280°C for 2 hours in air to obtain fibers, and then raising the temperature to 800°C at a heating rate of 5°C / min for 2 hours under the protection of nitrogen to obtain bismuth...

Embodiment 2

[0043] The preparation method of bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material for sodium ion battery of the present embodiment comprises the following steps:

[0044] 1) Add 1.0g of polyacrylonitrile (PAN) and 0.5g of bismuth chloride to 10mL of N,N-dimethylformamide (DMF), then stir overnight at 60°C to obtain an electrospinning solution;

[0045] 2) Add the electrospinning liquid obtained in step 1) into the syringe of the electrospinning device, set the distance between the syringe and the aluminum foil receiver to be 15cm, and the voltage of the applied high-voltage electrostatic field is 18kV, and then 1.2mL / Inject at a propulsion speed of h for electrospinning;

[0046]3) Calcining the filaments obtained by electrospinning in step 2) at 280°C for 2 hours in air to obtain fibers, and then raising the temperature to 800°C at a heating rate of 5°C / min for 2 hours under the protection of nitrogen to obtain bismuth / carbon Precursor;

[0...

Embodiment 3

[0050] The preparation method of bismuth phosphorus sulfur / carbon composite nanofiber negative electrode material for sodium ion battery of the present embodiment comprises the following steps:

[0051] 1) Add 1.0 g of polyacrylonitrile (PAN) and 1.0 g of bismuth chloride into 10 mL of N,N-dimethylformamide (DMF), then stir overnight at 60 °C to obtain a transparent viscous electrospun silk liquid;

[0052] 2) Add the electrospinning solution obtained in step 1) into the syringe of the electrospinning device, set the distance between the syringe and the aluminum foil receiver to be 18cm, and the voltage of the applied high-voltage electrostatic field is 25kV, and then 0.8mL / Injection at a propulsion speed of h for electrospinning;

[0053] 3) Calcining the filaments obtained by electrospinning in step 2) at 280°C for 2 hours in air to obtain fibers, and then raising the temperature to 800°C at a heating rate of 5°C / min for 2 hours under the protection of nitrogen to obtain b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com