Fibrous hollow hard carbon material capable of being used for sodium-ion battery negative electrode and preparation method thereof

A sodium-ion battery, fibrous technology, used in nanotechnology for materials and surface science, battery electrodes, carbon preparation/purification, etc., can solve problems such as increasing preparation costs and failing to achieve optimal kinetic performance, etc. Achieve the effect of improving resource utilization, good structural stability and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

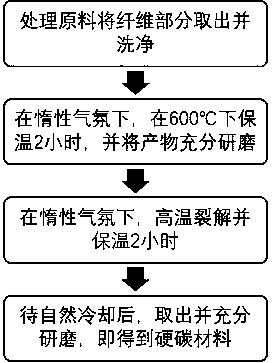

[0047] A kind of preparation method of fibrous hollow hard carbon material, the flow process of its preparation method is as follows figure 1 As shown, it specifically includes the following steps:

[0048] Step 1) Pretreatment of raw materials, take out the fibrous part of the biomass, wash it, dry it and put it in a graphite crucible, and keep it warm at 600°C for 2 hours under a protective atmosphere at a heating rate of 5°C / min for pre-carbonization Post-grinding to prevent fibrous hard carbon materials from hardening after direct pyrolysis at high temperature, resulting in difficulty in refinement, to obtain a precursor. The biomass is kapok fiber, poplar catkin fiber, catkin fiber, sycamore catkin, ramie or jute;

[0049] Step 2) High temperature pyrolysis, the precursor obtained in step 1 is placed in a graphite crucible, at a heating rate of 5°C / min, under a protective atmosphere, after high temperature pyrolysis for 2 hours, cooled naturally, taken out and ground to o...

Embodiment 2

[0051] This embodiment provides a method for performing an electrochemical test on the prepared fibrous hollow hard carbon material. The electrochemical test process is to make pole pieces for sodium-ion battery anode materials and assemble them into button-type batteries to test their electrochemical performance. Hard carbon material and sodium carboxymethyl cellulose binder solution are mixed uniformly at a ratio of 95:5 to obtain slurry, coated on aluminum foil, placed in a vacuum oven at 100°C for 2 hours, dried and cut into Φ10mm size , to get the required negative electrode sheet, the active material loading is 2mg / cm 2 about. The electrolyte system uses 1mol / L sodium perchlorate electrolyte, the solvent is ethylene carbonate and divinyl carbonate mixed at a volume ratio of 1:1 and 1mol / L sodium perchlorate electrolyte, the solvent is ethylene carbonate, carbonic acid Divinyl ester and fluoroethylene carbonate (FEC) were mixed at a volume ratio of 47.5:47.5:5 and assem...

Embodiment 3

[0053] A kind of preparation method of fibrous hollow hard carbon material, the steps not specified in the concrete steps are identical with the method preparation material in the embodiment 1, difference is: the raw material of described step 1 is jute fiber; Described step 2 The temperature of pyrolysis is 1200° C.; the atmosphere in the steps 1 and 2 is argon.

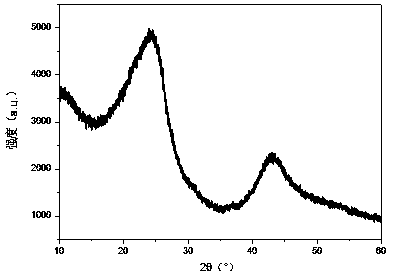

[0054] The fibrous hollow hard carbon material prepared in Example 3 is tested by X-ray diffraction (XRD), and the results are as follows: figure 2 As shown, two severely broadened diffraction peaks of the amorphous carbon curve can be obtained from the figure, and the graphite interlayer spacing is 0.3697 nm, which is beneficial to the storage of sodium ions.

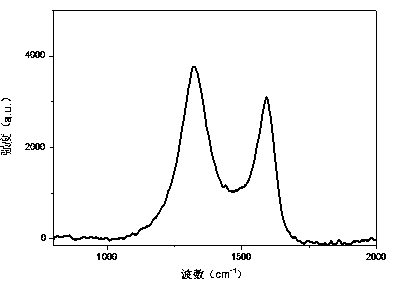

[0055] The fibrous hollow hard carbon material prepared in Example 3 is tested by Raman spectroscopy, and the results are as follows: image 3 As shown, the integrated intensity ratio of the two peaks I D / I G It is 1.6337, indicating that the material s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com