Quaternary polycrystalline positive electrode material, and preparation method and application thereof

A technology of positive electrode materials and positive electrode sheets, which is applied in the field of quaternary polycrystalline positive electrode materials and its preparation, can solve the problems of cycle performance and rate performance deterioration, poor cycle performance and rate performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a quaternary polycrystalline cathode material, the specific preparation method is as follows:

[0044] (1) Pre-burn nickel-cobalt-manganese-aluminum hydroxide (molar ratio: Ni:Co:Mn:Al=88:6:3:3) in an ordinary box-type furnace at 450°C in an air atmosphere for 8 hours, then cool, pulverize and Sieve to obtain nickel-cobalt-manganese-aluminum oxide;

[0045] (2) Dry-mix the nickel-cobalt-manganese-aluminum oxide obtained in step (1) with LiOH, selenium oxide and calcium oxide according to a molar ratio of 1:1.025:0.001:0.001 in a mixer, and dry mix The materials were calcined in an ordinary box furnace at 700° C. in an oxygen atmosphere for 8 hours, cooled, crushed and sieved to obtain the quaternary polycrystalline positive electrode material.

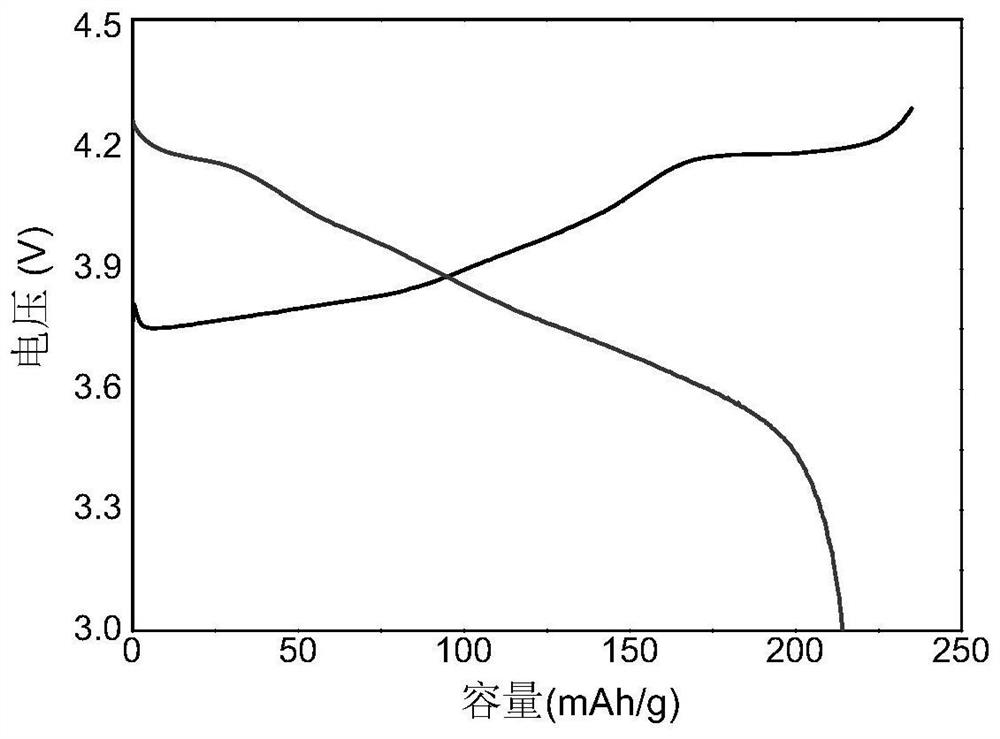

[0046] The first charge and discharge curve of the quaternary polycrystalline positive electrode material is as follows figure 1 shown.

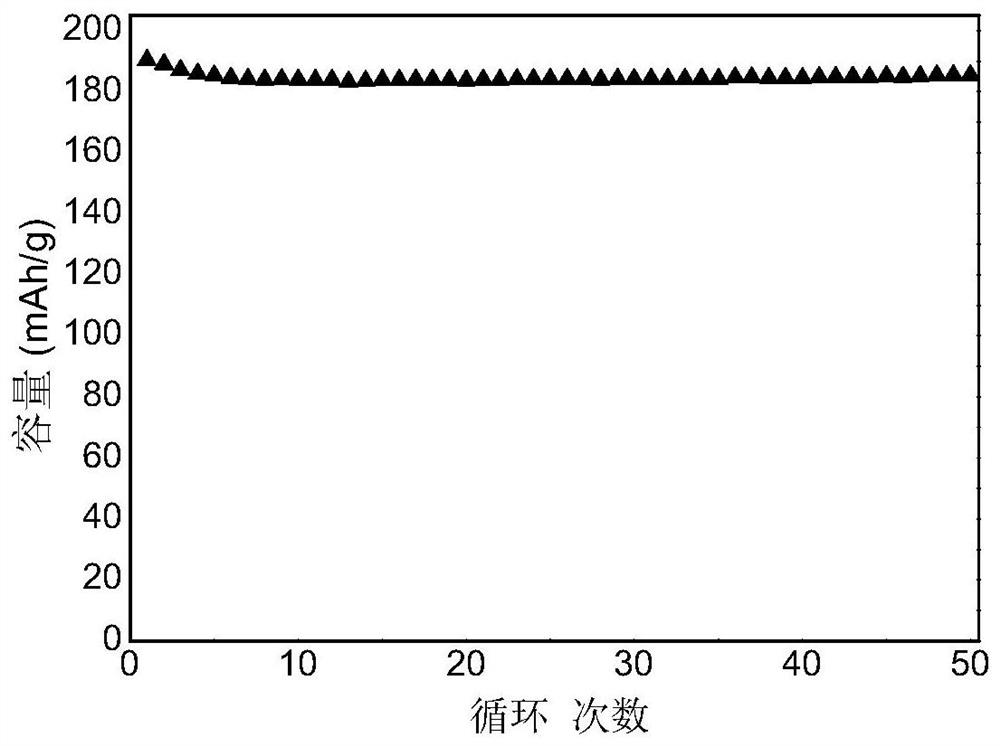

[0047] The cycle capacity retention curve of the quaternary po...

Embodiment 2

[0049] This embodiment provides a quaternary polycrystalline cathode material, the specific preparation method is as follows:

[0050] (1) After pre-burning nickel-cobalt-manganese-aluminum hydroxide (molar ratio: Ni:Co:Mn:Al=88:6:3:3) in an ordinary box-type furnace at 300°C in an air atmosphere for 7 hours, cool, pulverize and Sieve to obtain nickel-cobalt-manganese-aluminum oxide;

[0051] (2) Dry-mix the nickel-cobalt-manganese-aluminum oxide obtained in step (1) with lithium carbonate, selenium oxide and calcium oxide according to a molar ratio of 1:1.2:0.001:0.001 in a mixer, and dry mix The final material was calcined in an ordinary box furnace at 750° C. in an oxygen atmosphere for 6.5 hours, then cooled, crushed and sieved to obtain the quaternary polycrystalline positive electrode material.

Embodiment 3

[0053] The only difference between this embodiment and embodiment 1 is that the pre-burning temperature in step (1) is 150° C., and other conditions and parameters are exactly the same as those in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com