Preparation method of novel tin-based nanocrystalline alloy flexible film electrode

A technology of nanocrystalline alloys and flexible films, which is applied in electrode manufacturing, battery electrodes, electrode collector coatings, etc., can solve the problems of active material shedding and other problems, and achieve high production efficiency, convenient operation, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

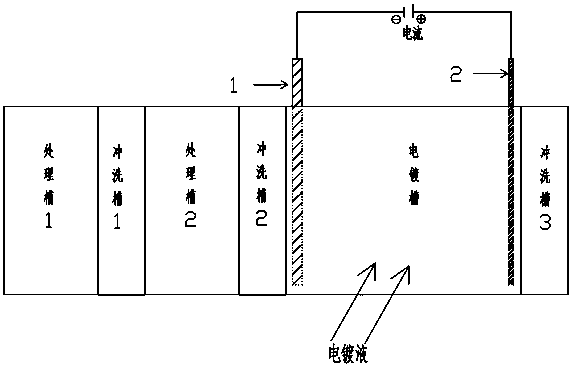

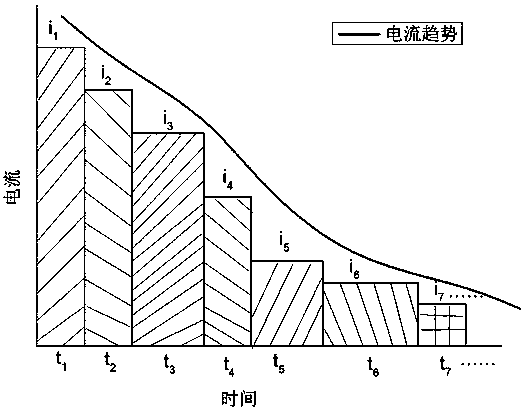

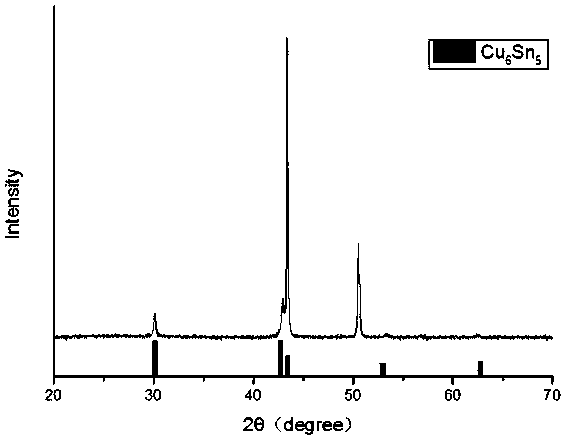

[0034] The tin-based nanocrystalline alloy flexible film electrode of the lithium ion battery of the present embodiment is prepared by the following method:

[0035] (1) get electroplating solution main salt and electroplating complexing agent preparation electroplating solution, the concentration of potassium pyrophosphate in this electroplating solution is 0.15mol / L, the concentration of cupric chloride is 0.06mol / L, the concentration of stannous pyrophosphate is 0.05mol / L, filter the prepared electroplating solution to remove impurities to obtain a transparent solution, namely electroplating solution A;

[0036] (2) Add gelatin, PEG800, sodium dodecylbenzenesulfonate and polyether polyol in electroplating solution A to obtain electroplating solution B as additive, gelatin, PEG800, sodium dodecylbenzenesulfonate in this electroplating solution B and the total concentration of polyether polyol is 5g / L;

[0037] (3) continue to add electroplating solution main salt cupric chl...

Embodiment 2

[0047] The tin-based nanocrystalline alloy flexible film electrode of the lithium ion battery of the present embodiment is prepared by the following method:

[0048] (1) get electroplating solution main salt and electroplating complexing agent preparation electroplating solution, the concentration of potassium pyrophosphate in this electroplating solution is 0.25mol / L, the concentration of cupric chloride is 0.06mol / L, the concentration of stannous pyrophosphate is 0.05mol / L, filter the prepared electroplating solution to remove impurities to obtain a transparent solution, namely electroplating solution A;

[0049] (2) Add gelatin, PEG400, sodium dodecylbenzenesulfonate and polyether polyol in electroplating solution A to obtain electroplating solution B as additive, gelatin, PEG400, sodium dodecylbenzenesulfonate in this electroplating solution B and the total concentration of polyether polyol is 15g / L;

[0050] (3) continue to add electroplating solution main salt copper ch...

Embodiment 3

[0059] The tin-based nanocrystalline alloy flexible film electrode of the lithium ion battery of the present embodiment is prepared by the following method:

[0060] (1) Get electroplating solution main salt and electroplating complexing agent preparation electroplating solution, the concentration of potassium pyrophosphate in this electroplating solution is 0.4mol / L, the concentrated acid of potassium phosphate is 0.2mol / L, the concentration of cupric chloride is 0.12 mol / L, the concentration of tin protochloride is 0.1mol / L, the electroplating solution that will prepare is filtered to remove impurity and obtain transparent solution and be electroplating solution A;

[0061] (2) Add gelatin, glucose, PEG400, PEG800, sodium lauryl sulfate and methoxypolyoxyethylene ether in electroplating solution A to obtain electroplating solution B as additives, gelatin, glucose, PEG400, PEG800 in this electroplating solution B The total concentration of sodium lauryl sulfate and sodium lau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com