Anthraquinone-2-copper carboxylate/graphene nano-composite as well as preparation and application thereof

A nanocomposite, copper carboxylate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as performance deterioration, achieve low equipment requirements, multi-intercalation lithium active sites, Avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

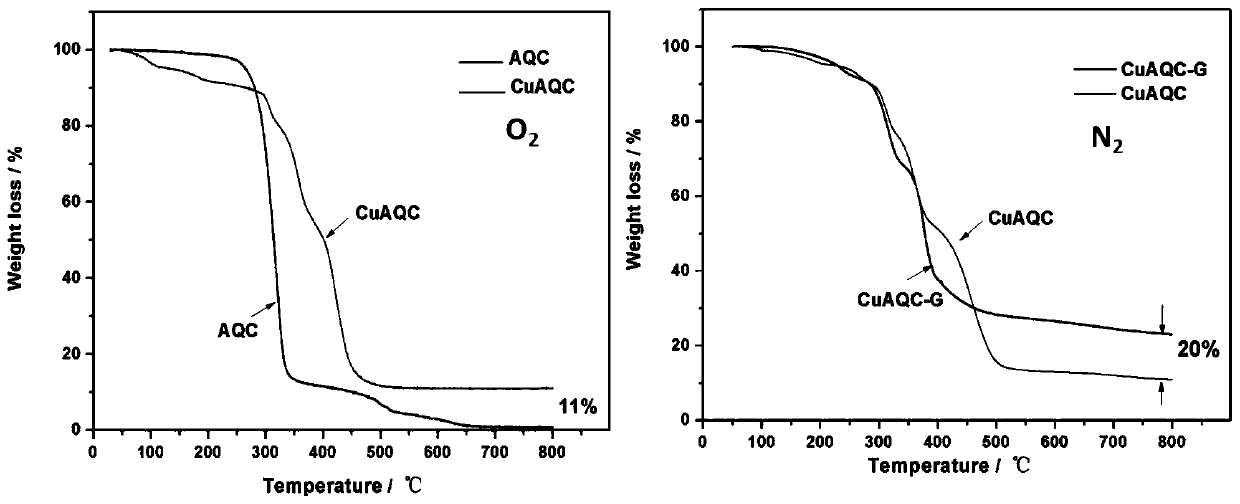

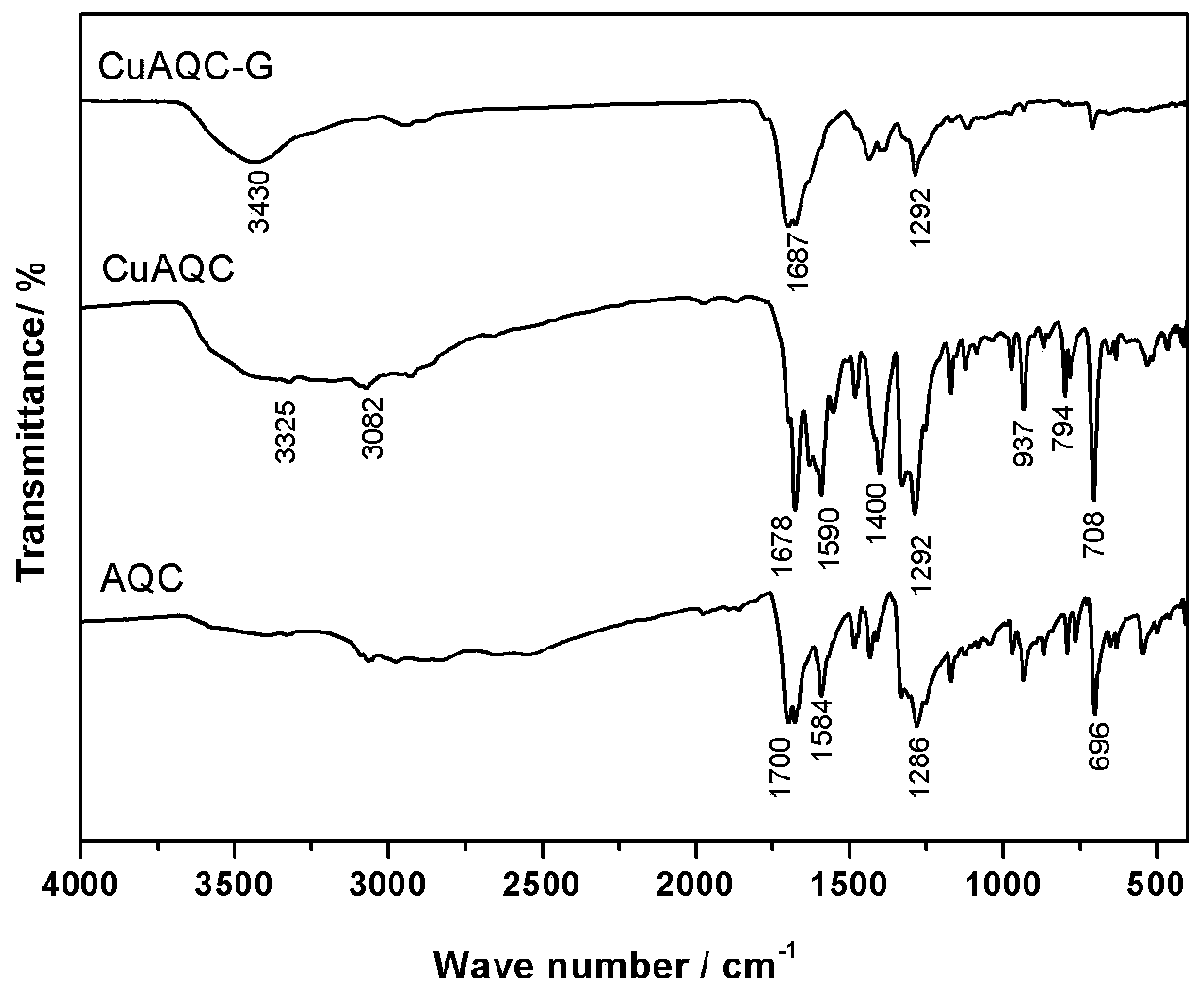

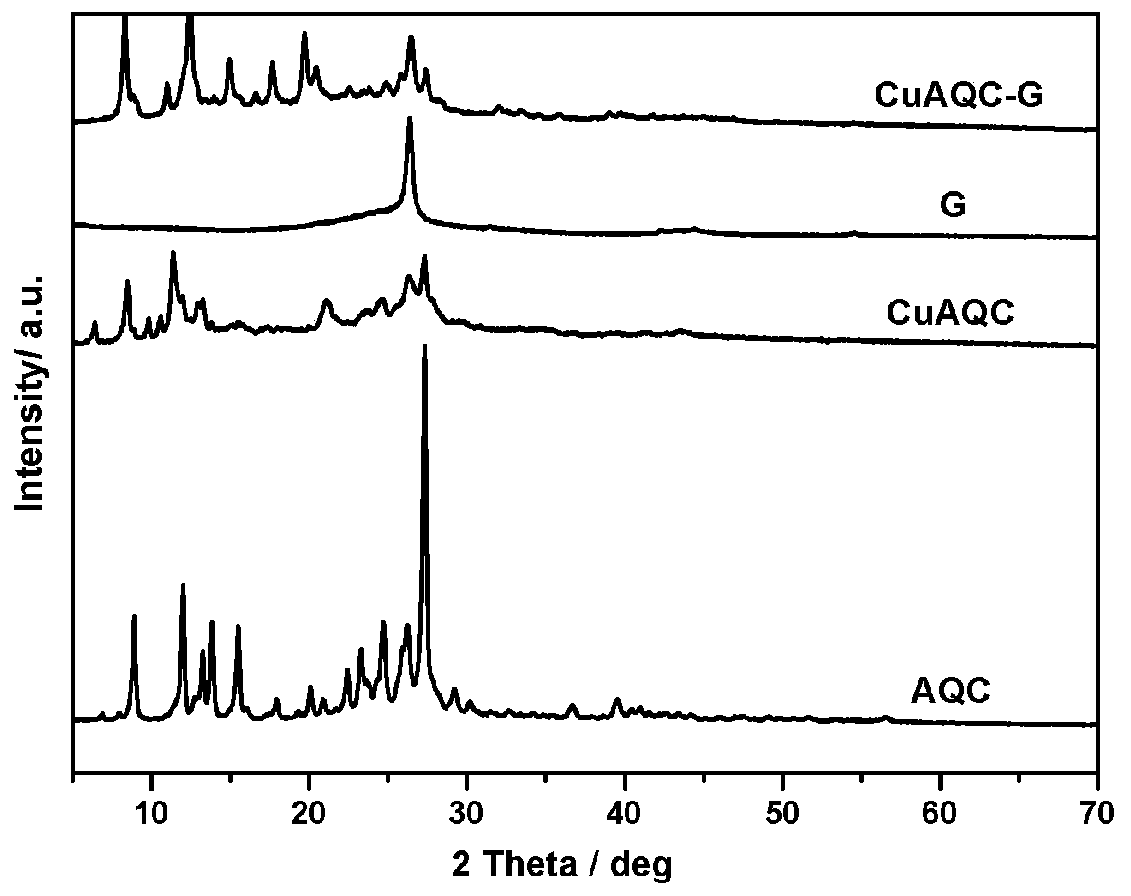

[0038] (1) Dissolve 0.2520g of anthraquinone-2-carboxylic acid (AQC) in 13mL of N,N-dimethylformamide and stir in an oil bath at 60°C, then gradually add 1mL of 0.64mol / L Cu (NO 3 ) 2 The solution was heated to 80°C for reflux and stirred for 10 hours. After stopping the heating, it was cooled to obtain a blue precipitate, which was precipitated in 20ml of deionized water, washed with deionized water, and then dried in a blast drying oven at 80°C for 24 hours to obtain anthraquinone - 2-Carboxylate copper salt compound (CuAQC).

[0039] (2) disperse 0.08g CuAQC prepared in step (1) in the N-methylpyrrolidone solvent of 8mL together with 0.02g graphene after being ground in an agate mortar for half an hour, put it into a quartz ball mill jar at 2600r / min Ball mill for 4 hours, and then sonicate for 2 hours to make a turbid solution.

[0040] (3) Transfer the turbid liquid obtained in step (2) to a blast drying oven, and blow dry the co-precipitation at a temperature of 80° C...

Embodiment 2

[0052] (1) Dissolve 0.2520g of anthraquinone-2-carboxylic acid (AQC) in 11mL of methanol and stir in an oil bath at 60°C, then gradually add 1.5mL of 0.50mol / L Cu(NO 3 ) 2 The solution was heated to 75°C for reflux and stirred for 13 hours. After stopping the heating, it was cooled to obtain a blue precipitate, which was then precipitated in 25ml of deionized water, washed with deionized water, and then dried in a blast drying oven at 80°C for 24 hours to obtain anthraquinone - 2-Carboxylate copper salt compound (CuAQC).

[0053] (2) The 0.08g CuAQC prepared in step (1) was ground in a quartz grinder for half an hour and dispersed in 10mL of acetone solvent together with 0.015g graphene, put into a quartz ball mill jar and ball milled for 4 hour to make a turbid solution, and then sonicate for 1.5 hours.

[0054] (3) Transfer the turbid liquid obtained in step (2) to a blast drying oven, and blow dry the co-precipitation at a temperature of 60°C for 60 hours to obtain anthra...

Embodiment 3

[0057] (1) Dissolve 0.2520g of anthraquinone-2-carboxylic acid (AQC) in 15mL of ethanol and stir at 70°C, then gradually add 0.8mL of 0.95mol / L Cu(NO 3 ) 2 solution. Heat up to 90°C and reflux and stir for 8 hours. After stopping heating, cool to obtain a blue precipitate. The obtained precipitate is precipitated in 15ml of deionized water, washed with deionized water, and then dried in a blast drying oven at 90°C for 18 hours to obtain anthraquinone-2 - copper carboxylate compound (CuAQC).

[0058] (2) The 0.08g LiAQC prepared by step (1) is ground in a quartz grinder for half an hour and dispersed into 11mL of ethanol solvent together with 0.014g graphene, put into a quartz ball mill jar and ball mill for 4 hours, and then sonicated for 1.5 hours to make a turbid solution.

[0059] (3) Transfer the turbid liquid obtained in step (2) to a blast drying oven, and blow and dry the co-precipitation at a temperature of 60° C. for 48 hours to obtain anthraquinone-2-carboxylate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com