Sodium ion pre-embedded MoO3 nanobelt as well as preparation method and application of sodium ion pre-embedded MoO3 nanobelt

A nanobelt and sodium ion technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of low electrical conductivity, structural damage, limited development and application, etc., and achieve the effect of improving electrical conductivity, improving electrochemical performance, and avoiding large attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

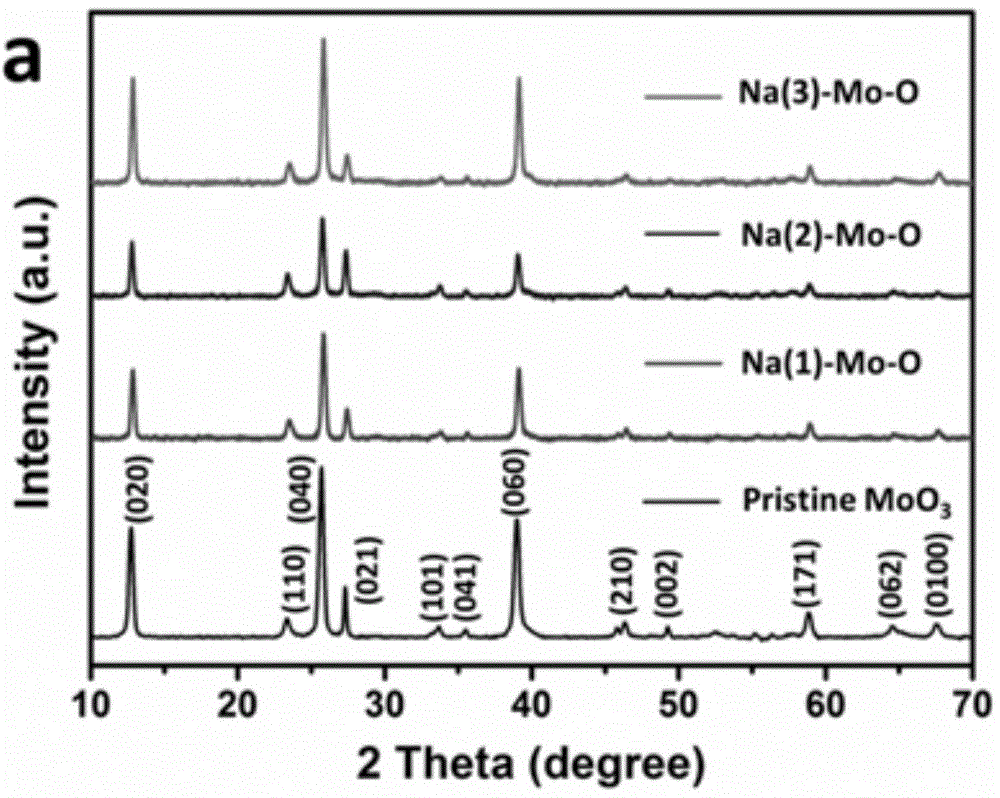

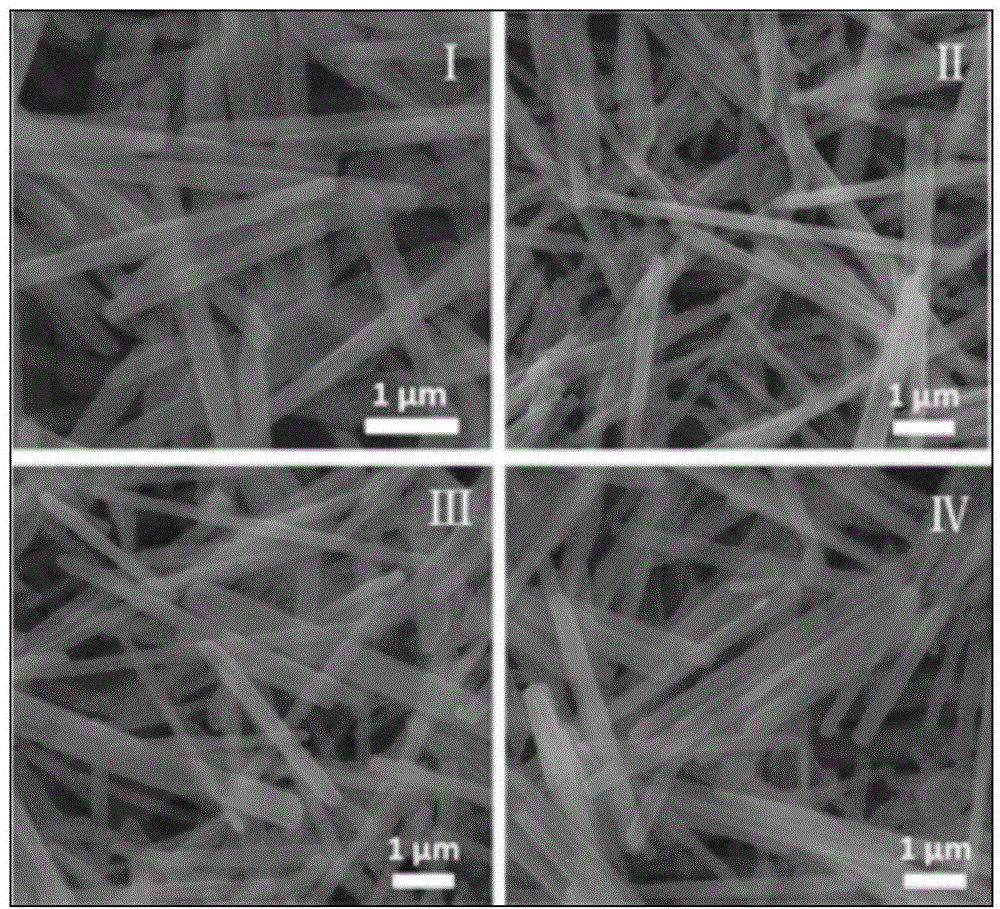

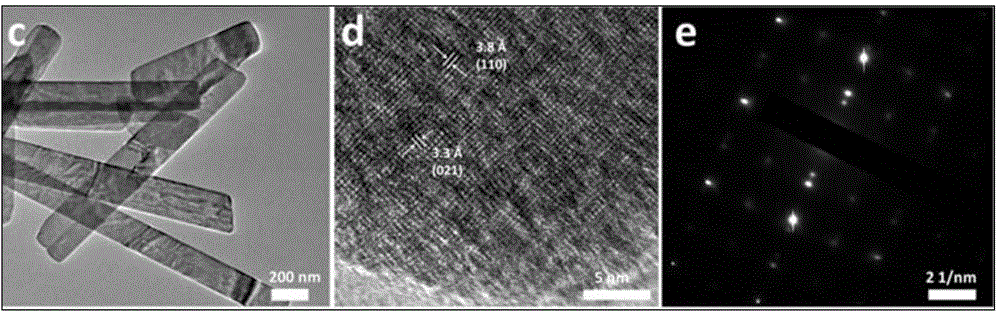

[0029] Sodium ion pre-intercalated MoO 3 The preparation method of nanobelt comprises the following steps:

[0030] 1) in 40ml 30% H 2 o 2 Slowly add 4g of molybdenum powder, then add an appropriate amount of deionized water, stir to obtain an orange acid solution, and then place it in a water bath at 70°C for 4 hours;

[0031] 2) Transfer the solution obtained in step 1) into a 100ml reaction kettle, put it in an oven at 180°C for 6 hours, then take it out and cool it to room temperature;

[0032] 3) The product obtained in step 2) was centrifuged, washed repeatedly with deionized water and ethanol, and then dried in an oven at 70°C to obtain MoO 3 nanobelt;

[0033] 4) Add 0.36g of the product obtained in step 3), 0.3g of PEG4000 and 1mmol NaCl to an appropriate amount of deionized water, and stir for 2h;

[0034] 5) Transfer the solution obtained in step 4) into a 100ml reactor, put it in an oven at 180°C for 2 days, then take it out and cool it to room temperature;

...

Embodiment 2

[0045] Sodium ion pre-intercalated MoO 3 The preparation method of nanobelt comprises the following steps:

[0046] 1) in 40ml 30% H 2 o 2 Slowly add 4g of molybdenum powder, then add an appropriate amount of deionized water, stir to obtain an orange acid solution, and then place it in a water bath at 70°C for 4 hours;

[0047] 2) Transfer the solution obtained in step 1) into a 100ml reaction kettle, put it in a 160°C oven for 6 hours, then take it out and cool it to room temperature;

[0048] 3) The product obtained in step 2) was centrifuged, washed repeatedly with deionized water and ethanol, and then dried in an oven at 70°C to obtain MoO 3 nanobelt;

[0049] 4) Add 0.36g of the product obtained in step 3), 0.3g of PEG4000 and 1mmol NaCl to an appropriate amount of deionized water, and stir for 2h;

[0050] 5) Transfer the solution obtained in step 4) into a 100ml reaction kettle, put it in an oven at 180°C for 3 days, and then take it out and cool it to room tempera...

Embodiment 3

[0054] Sodium ion pre-intercalated MoO 3 The preparation method of nanobelt comprises the following steps:

[0055] 1) in 40ml 30% H 2 o 2 Slowly add 4g of molybdenum powder, then add an appropriate amount of deionized water, stir to obtain an orange acid solution, and then place it in a water bath at 70°C for 4 hours;

[0056] 2) Transfer the solution obtained in step 1) into a 100ml reaction kettle, put it in an oven at 180°C for 6 hours, then take it out and cool it to room temperature;

[0057] 3) The product obtained in step 2) was centrifuged, washed repeatedly with deionized water and ethanol, and then dried in an oven at 70°C to obtain MoO 3 nanobelt;

[0058] 4) Add 0.36g of the product obtained in step 3), 0.3g of PEG4000 and 1mmol NaCl to an appropriate amount of deionized water, and stir for 2h;

[0059] 5) Transfer the solution obtained in step 4) into a 100ml reactor, put it in an oven at 200°C for 2 days, then take it out and cool it to room temperature;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com