NCMA quaternary system material and preparation method thereof, lithium battery positive electrode material and lithium battery

A cathode material and quaternary system technology, applied in the field of lithium battery cathode materials and lithium batteries, can solve the problem of low electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In another typical implementation of the present application, a preparation method of NCMA quaternary material is provided, the preparation method includes: step S1, using Co 3 o 4 and V 2 o 5 Attaching the NCMA quaternary cathode material to obtain the attached material; and step S2, performing a second firing on the attached material to obtain the NCMA quaternary system material.

[0030] Co 3 o 4 and V 2 o 5 coated on the NCMA quaternary cathode material to obtain Co 3 o 4 and V 2 o 5 Co-coated NCMA quaternary materials. coated Co 3 o 4 The main purpose is to remove the residual alkali (LiOH and LiOH) on the surface of the NCMA quaternary cathode material through chemical reaction. 2 CO 3 ), thereby reducing the pH value of the material, and then will not cause the gelation of the positive electrode slurry during the subsequent homogenate coating process in battery preparation, which increases the transmission channel of lithium ions from the aspect of ...

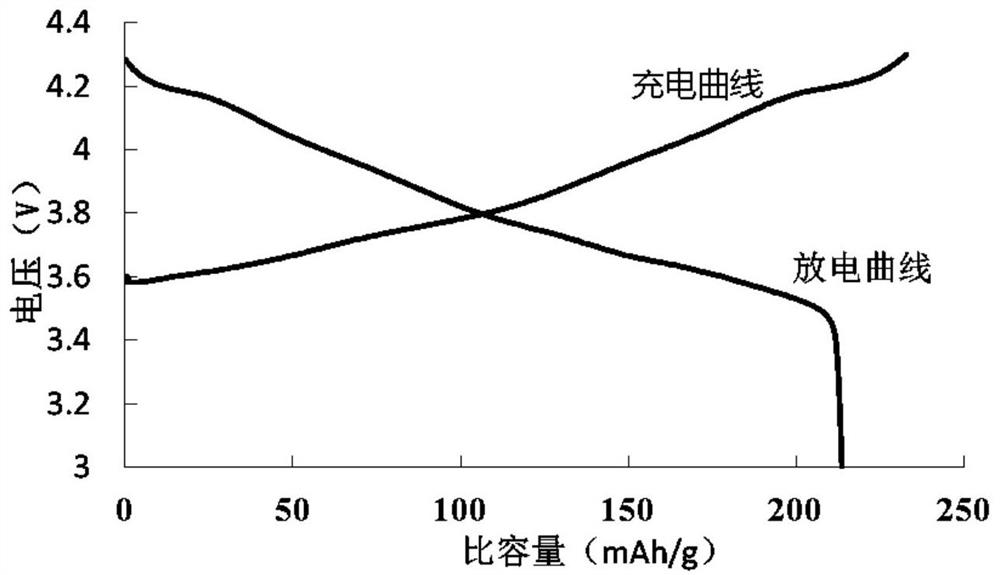

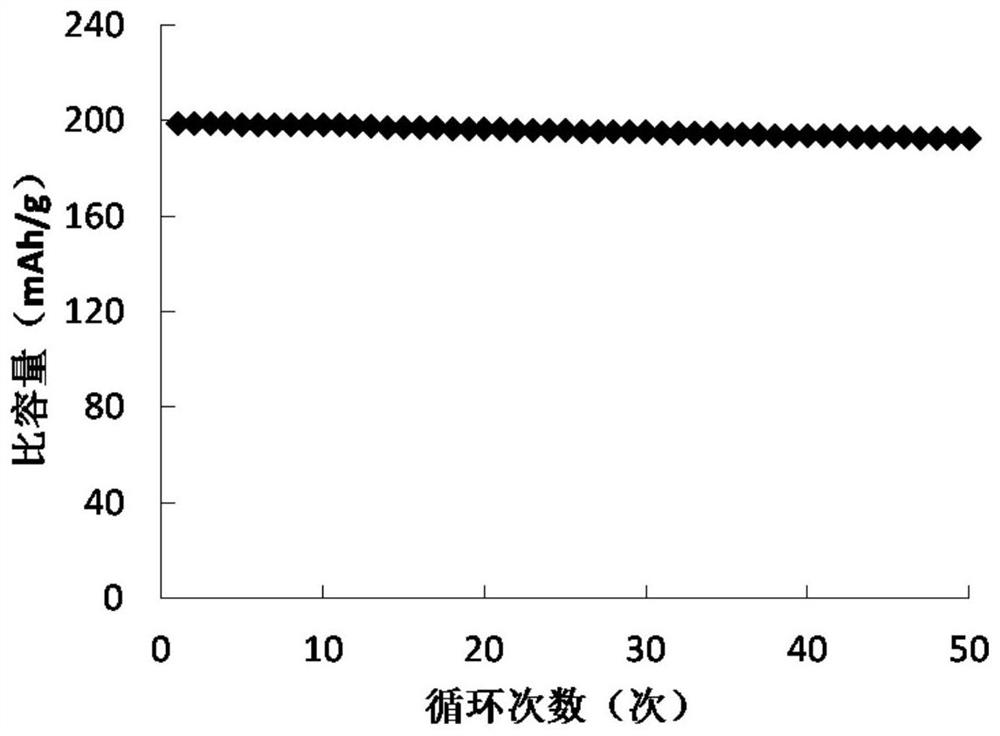

Embodiment 1

[0043] Nickel-cobalt-manganese-aluminum four-element composite hydroxide (Henan Kelong New Energy Co., Ltd., molar ratio: Ni:Co:Mn:Al=88:6:3:3) and LiOH according to the molar ratio of 1:1.025 (Li / Metal=1.025) Stir and mix directly in the mixer to get the mixture, roast the mixture in an ordinary box furnace at 700°C under an oxygen atmosphere for 8 hours, cool, pulverize and sieve to obtain NCMA quaternary with a particle size of 12 μm Cathode material, the chemical formula of the NCMA quaternary cathode material is LiNi 0.88 co 0.06 mn 0.03 al 0.03 .

[0044] The NCMA quaternary cathode material, Co 3 o 4 and V 2 o 5 According to the mass ratio of 1:0.005:0.005 for dry mixing, Co 3 o 4 and V 2 o 5 The powder is evenly attached to the surface of the NCMA quaternary cathode material to obtain the attached material. The adhered material was calcined in an oxygen atmosphere at 500°C for 8 hours, then cooled, crushed, and sieved to obtain the NCMA quaternary material...

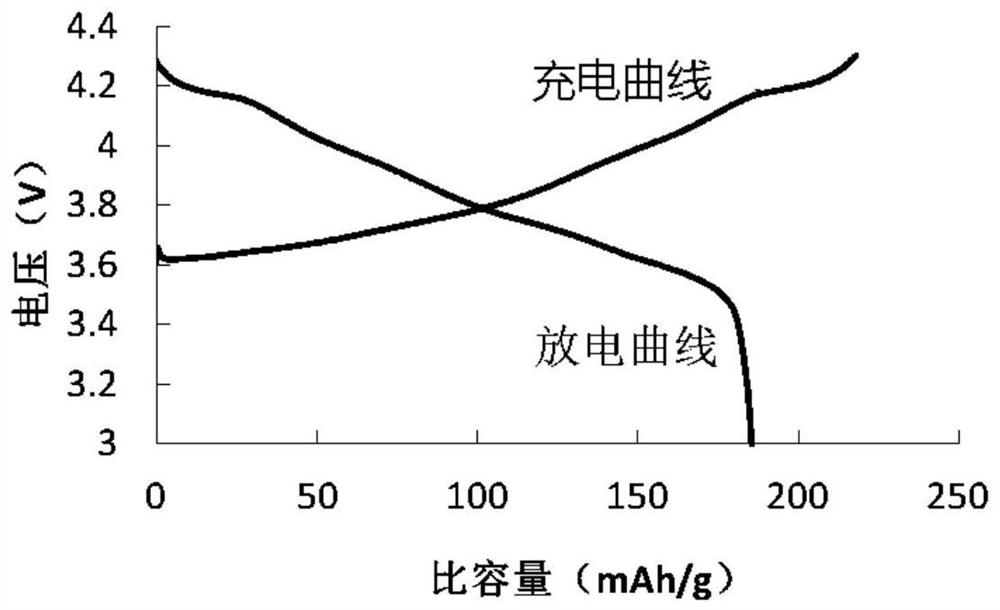

Embodiment 2

[0046]The difference between embodiment 2 and embodiment 1 is that

[0047] The NCMA quaternary cathode material, Co 3 o 4 and V 2 o 5 Stir and mix directly according to the mass ratio of 1:0.001:0.001, and finally obtain the NCMA quaternary system material. The thickness of the cladding layer of the NCMA quaternary system material is 1nm, Co 3 o 4 The mass ratio to NCMA quaternary cathode material is 0.001:1, V 2 o 5 The mass ratio of the NCMA quaternary cathode material is 0.001:1, and the chemical formula of the NCMA quaternary system material is LiNi 0.88 co 0.06 mn 0.03 al 0.03 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com