Method for preparing lithium cobaltate composite electrode material coated by iron phosphate

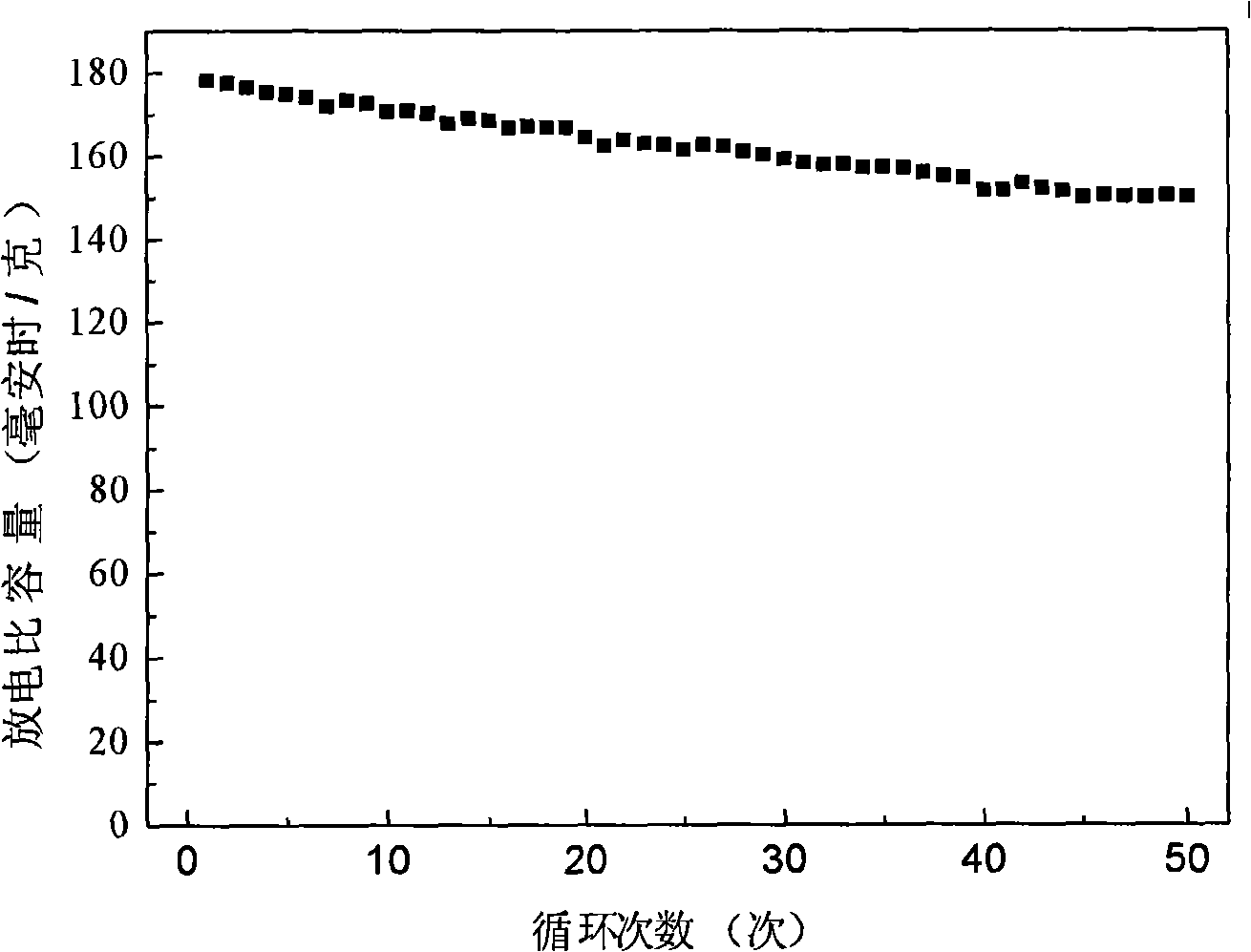

A technology of iron phosphate coating lithium cobalt oxide and composite electrodes, which is applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of loss of electrode material mass specific capacity, crystal structure damage, high price, etc., and achieve good results. Electrochemical cycle performance, improved cycle performance, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 48.5g of LiCoO 2 material and 4.05g of Fe(NO 3 ) 3 9H 2 O, add 100mL deionized water to prepare Fe 3+ The suspension with a concentration of 0.1mol / L was ultrasonically treated for 30 minutes at a temperature of 25°C and a power of 2000W / L. Add dropwise 0.1mol / L of (NH 4 ) 2 HPO 4 Solution 120mL, where n(PO 4 3- ) / n(Fe 3+ )=1.2 / 1 (molar ratio), continue stirring for 1 hour after the dropwise addition is completed. After the reaction is completed, filter and wash with deionized water until the pH value of the filtrate is 7. The filter cake was dried in an oven at 130° C. for 6 hours, and ground for later use.

[0033] The powder material obtained by grinding is heated up to 550°C at a rate of 5°C / min, kept at a constant temperature for 10 hours, and then naturally cooled to room temperature to obtain the product of the present invention.

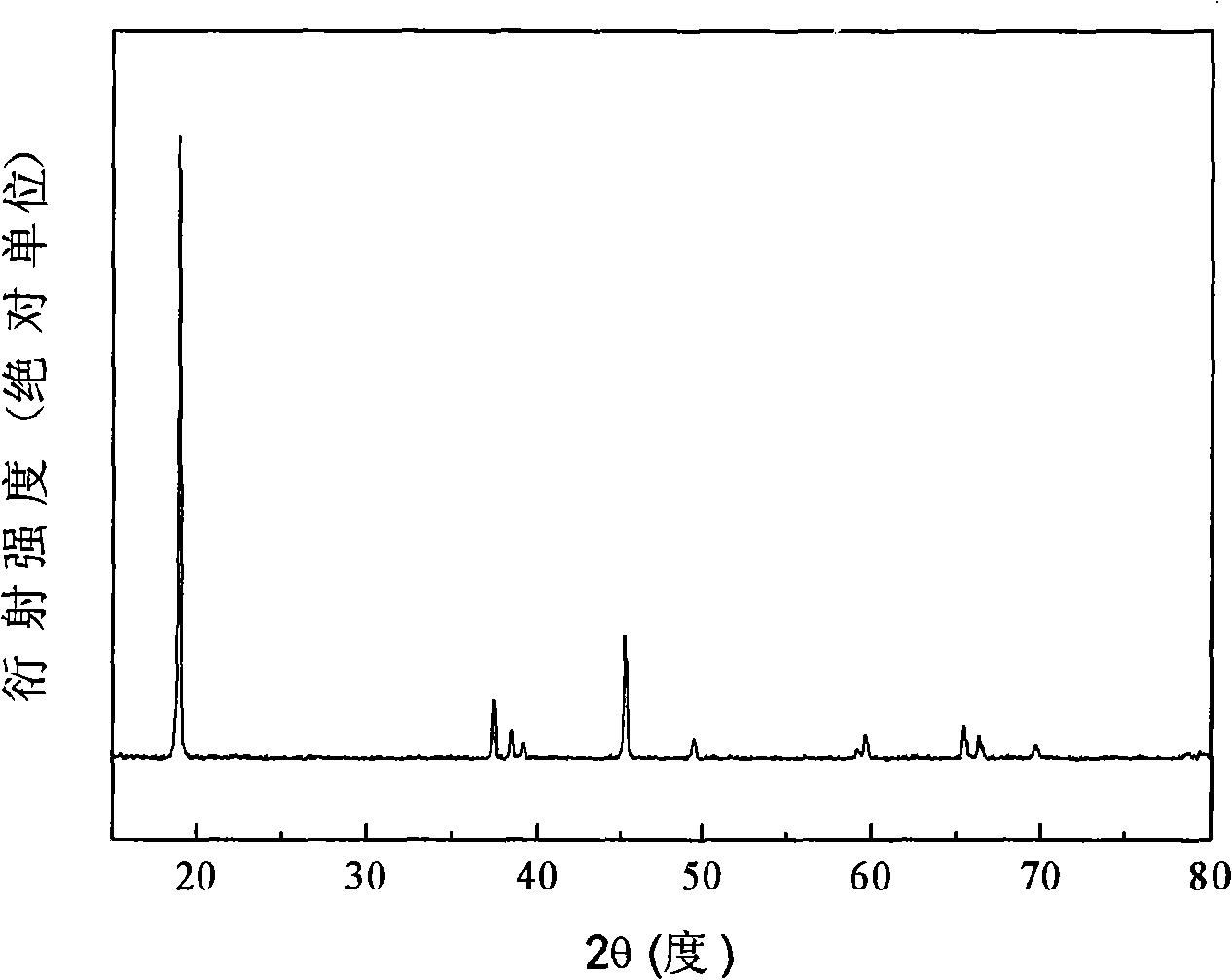

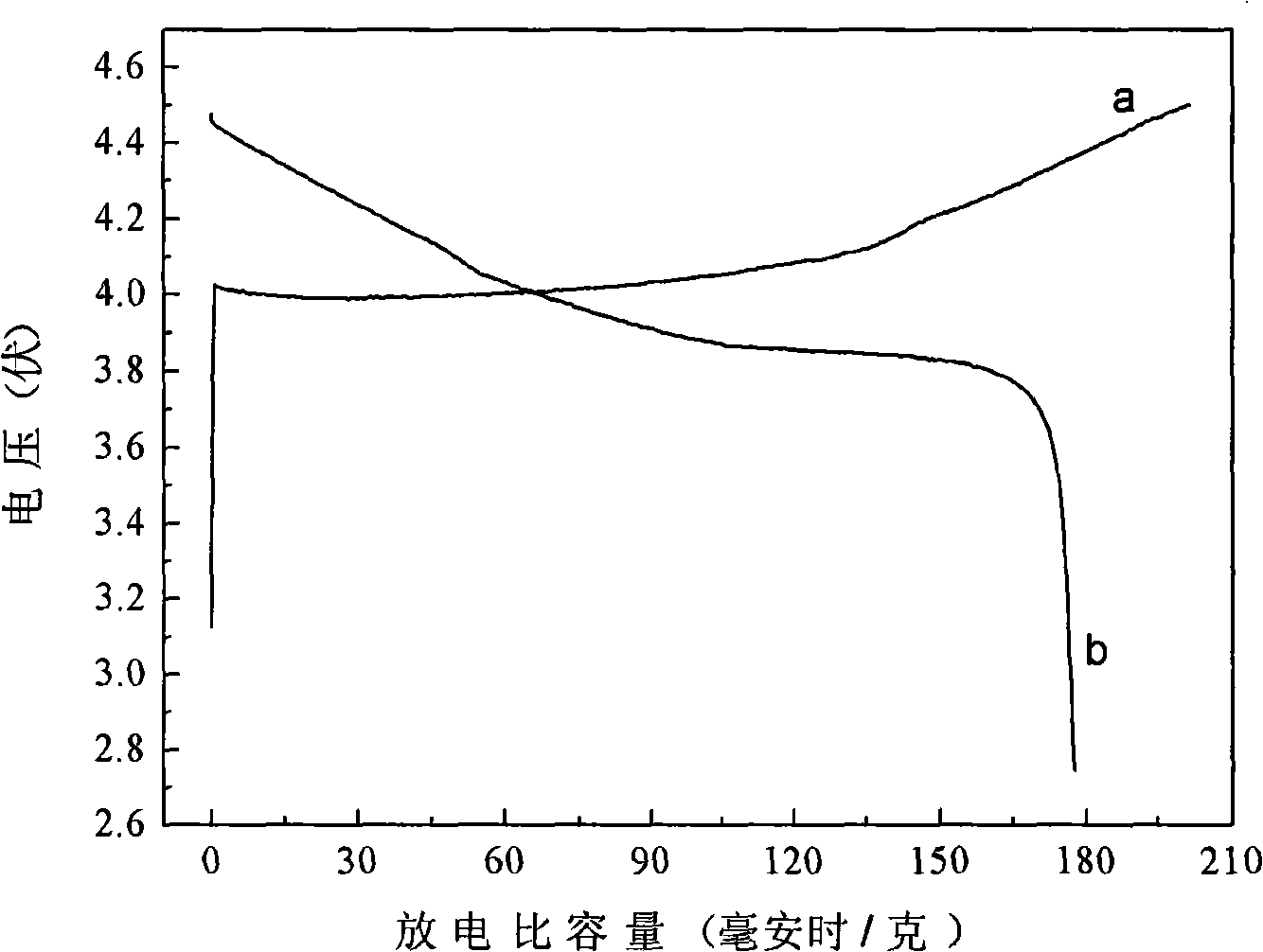

[0034] Using the Japan Shimadzu ICPS-7500 inductively coupled plasma emission spectrometer to measure the content o...

Embodiment 2

[0036] Weigh 74.5g of LiCoO 2 material and 2.02g of Fe(NO 3 ) 3 9H 2 O, add 100mL deionized water to prepare Fe 3+ The suspension with a concentration of 0.05mol / L was subjected to ultrasonic treatment for 60 minutes at a temperature of 20°C and a power of 800W / L. Add dropwise 0.05mol / L of (NH 4 ) 2 HPO 4 Solution 150mL, where n(PO 4 3- ) / n(Fe 3+ )=1.5 / 1 (molar ratio), continue stirring for 0.5 hour after the dropwise addition is completed. After the reaction is completed, filter and wash with deionized water until the pH value of the filtrate is 7. The filter cake was dried in an oven at 50° C. for 12 hours, and ground for later use.

[0037] The powder material obtained by grinding is heated up to 350°C at a rate of 2°C / min, kept at a constant temperature for 15 hours, and then naturally cooled to room temperature to obtain the product of the present invention. ICP and XRD tests show that the product composition is 5wt.% FePO 4 Coated LiCoO 2 The composite mate...

Embodiment 3

[0039] Weigh 84.8g of LiCoO 2 material and 12.12g of Fe(NO 3 ) 3 9H 2 O, add 100mL deionized water to prepare Fe 3+ Suspension with a concentration of 0.3mol / L is ultrasonically treated for 45 minutes at a temperature of 40°C and a power of 1000W / L. Add dropwise 0.3mol / L of (NH 4 ) 2 HPO 4 Solution 100mL, where n(PO 4 3- ) / n(Fe 3+ )=1 / 1 (molar ratio), continue stirring for 1 hour after the dropwise addition is completed. After the reaction is completed, filter and wash with deionized water until the pH value of the filtrate is 7. The filter cake was dried in an oven at 120° C. for 12 hours, and ground for later use.

[0040] The powder material obtained by grinding is heated up to 450°C at a rate of 10°C / min, kept at a constant temperature for 10 hours, and then naturally cooled to room temperature to obtain the product of the present invention. ICP and XRD tests show that the product composition is 1wt.% FePO 4 Coated LiCoO 2 The composite material belongs to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com