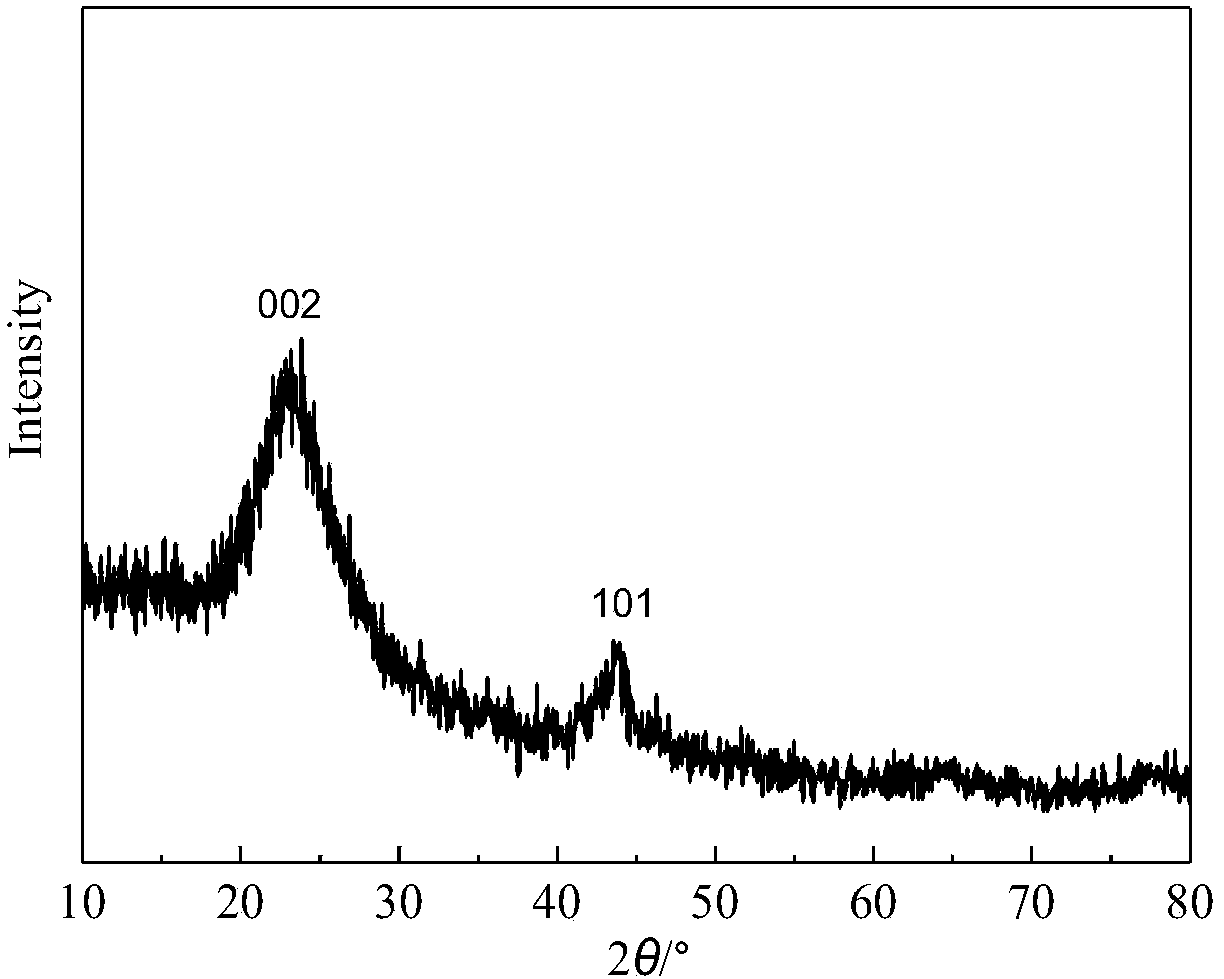

Method for preparing modified graphite negative electrode material of sodium ion battery

A sodium-ion battery, graphite anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unstable graphene stacking structure, no sodium-ion battery, high irreversible capacity, and reduce the first irreversible capacity. , the effect of a wide range of raw materials and a simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Take 200mL98% concentrated H 2 SO 4 Add to the reaction vessel placed in the ice bath, stir at 20rpm, then add 10g of natural flake graphite with a particle size of 10-30μm and 30g of KMnO 4 Add it into the reactor and react for 30 minutes; then transfer the above reaction solution into a warm water bath at 39±1°C and continue stirring for 30 minutes; then raise the temperature of the reaction solution to 95-98°C, add 600mL deionized water and continue stirring for 30 minutes; finally add 60 mL of H with a mass fraction of 5% 2 o 2 Mix well, filter while hot, wash the filter residue with HCl with a mass fraction of 5%, until there is no SO in the filtrate 4 2- (with BaC1 2 solution detection), then fully washed with deionized water to neutrality, vacuum filtration, to obtain paste-like graphite oxide;

[0029] (2) Add 0.8g of water-based phenolic resin into 28mL of deionized water, fully dissolve, then add 8g of the paste-like graphite oxide obtained in step 2...

Embodiment 2

[0034] (1) Take 250mL95% concentrated H 2 SO 4 Add it to the reaction vessel placed in the ice bath, stir at 100rpm, then add 10g of natural flake graphite with a particle size of 10-30μm and 40g of KMnO 4 Add it into the reactor and react for 60 minutes; then transfer the above reaction solution into a warm water bath at 41±1°C and continue stirring for 60 minutes; then raise the temperature of the reaction solution to 98-100°C, add 1250mL deionized water and continue stirring for 60 minutes; 125 mL mass fraction of 5% H 2 o 2 Mix well, filter while hot, wash the filter residue with HCl with a mass fraction of 5%, until there is no SO in the filtrate 4 2- (with BaC1 2 solution detection), then fully washed with deionized water to neutrality, vacuum filtration, to obtain paste-like graphite oxide;

[0035] (2) Add 4g of petroleum pitch into 40mL of kerosene, fully dissolve, then add 8g of graphite oxide prepared in step 2, stir at 100rpm until uniformly mixed, and dry at...

Embodiment 3

[0039] (1) Take 230mL98% concentrated H 2 SO 4 Add it to the reaction vessel placed in the ice bath, stir at 50rpm, then add 10g of artificial graphite with a particle size of 1-10μm and 35g of KMnO 4 Add it into the reactor and react for 45 minutes; then transfer the above reaction solution into a warm water bath at 40±2°C and continue stirring for 45 minutes; then raise the temperature of the reaction solution to 98±2°C, add 920mL deionized water and continue stirring for 45 minutes; finally add 92 mL mass fraction of 5% H 2 o 2 Mix well, filter while hot, wash the filter residue with HCl with a mass fraction of 5%, until there is no SO in the filtrate 4 2- (with BaC1 2 solution detection), then fully washed with deionized water to neutrality, vacuum filtration, to obtain paste-like graphite oxide;

[0040] (2) Add 2.0g of glucose into 50mL of deionized water, fully dissolve, then add 8g of the paste graphite oxide obtained in step 2, stir until evenly mixed, and dry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com