Nitrogen-doped porous carbon nanofiber sodium ion battery negative electrode material and preparation method thereof

A sodium-ion battery, nanofiber technology, applied in battery electrodes, secondary batteries, chemical characteristics of fibers, etc., can solve the problems of volume expansion, poor electrical conductivity of electrode materials, etc., and achieve easy operation, low cost, and infiltration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

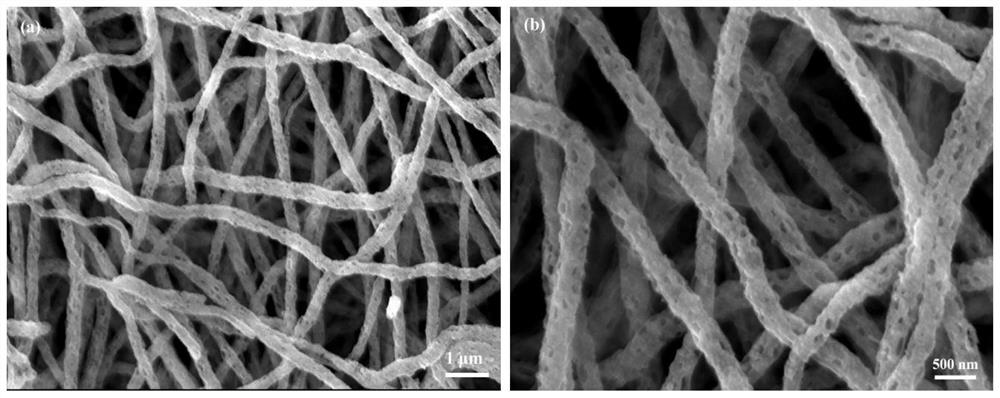

Image

Examples

Embodiment 1

[0034] In this embodiment, a method for preparing a nitrogen-doped-porous carbon nanofiber sodium-ion battery negative electrode material comprises the following steps:

[0035] (1) Take by weighing PVP solid 0.9g, be dissolved in the deionized water of 5.1g, fully stir 2h; Add the PTFE emulsion that the mass fraction of 3g is 60% again, stir 1h again, obtain electrospinning stoste; Polyvinylpyrrolidone ( PVP), molecular weight not less than 1,300,000;

[0036] (2) Use a 10mL syringe to draw 8mL of electrospinning stock solution, and spin in an electrospinning machine with a temperature of 25°C and a humidity of 35%; the distance between the needle and the receiver during spinning is 20cm, and the speed of the receiver is 100r / min, the needle advance speed is 1mL / h, and the voltage is 20kv; then the obtained fiber is dried in an oven at 80°C for 12h; The temperature was raised to 250°C for 3 hours at a heating rate of 1°C / min, and the fiber film was pre-oxidized to stabilize ...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, especially in that:

[0043] In this embodiment, a method for preparing a nitrogen-doped-porous carbon nanofiber sodium-ion battery negative electrode material comprises the following steps:

[0044] (1) Take by weighing PVP solid 0.3g, be dissolved in the deionized water of 5.1g, fully stir 1h; Add the PTFE emulsion that the mass fraction of 3g is 60% again, stir 2h again, obtain electrospinning stoste; Polyvinylpyrrolidone ( PVP), molecular weight not less than 1,300,000;

[0045] (2) Use a 10mL syringe to draw 8mL of electrospinning stock solution, and spin in an electrospinning machine with a temperature of 25°C and a humidity of 35%; the distance between the needle and the receiver during spinning is 20cm, and the speed of the receiver is 100r / min, the needle advance speed is 1mL / h, and the voltage is 20kv; then the obtained fiber is dried in an oven at 60°C for 18h; The temperature was raised to 280°C at a hea...

Embodiment 3

[0048] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0049] In this embodiment, a method for preparing a nitrogen-doped-porous carbon nanofiber sodium-ion battery negative electrode material comprises the following steps:

[0050] (1) Take by weighing PVP solid 0.6g, be dissolved in the deionized water of 5.1g, fully stir 2h; Add the PTFE emulsion that the mass fraction of 3g is 60% again, stir 1h again, obtain electrospinning stoste; Polyvinylpyrrolidone ( PVP), molecular weight not less than 1,300,000;

[0051] (2) Use a 10mL syringe to draw 8mL of electrospinning stock solution, and spin in an electrospinning machine with a temperature of 25°C and a humidity of 35%; the distance between the needle and the receiver during spinning is 20cm, and the speed of the receiver is 100r / min, the needle advance speed is 1mL / h, and the voltage is 20kv; then the obtained fiber is dried in an oven at 80°C for 12h; The temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com