High-circulation and high-magnification rate carbon-based negative electrode energy storage composite material and preparation method thereof

A composite material and high-magnification technology, applied in the field of materials science, can solve problems such as capacity attenuation and volume expansion, and achieve the effects of preventing agglomeration, inhibiting volume change, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A high-cycle, high-rate carbon-based negative electrode energy storage composite material is prepared by a method comprising the following steps:

[0068] (1), preparation of nickel hydrogel

[0069] Put 1g of polymer water-absorbent resin into the reaction vessel, then add 20ml of nickel salt solution, control the temperature at 45°C and shake in a constant temperature water bath for 8 hours to obtain nickel salt gel;

[0070] Described nickel salt aqueous solution, the nickel acetate aqueous solution that is about to join the nickel acetate crystal to obtain in distilled water is the nickel acetate aqueous solution of 0.025g / ml;

[0071] The amount of polymer resin and nickel salt solution is calculated by mass ratio, polymer resin: nickel acetate in nickel salt solution is 1:0.5;

[0072] The polymer water-absorbing resin is sodium polyacrylate;

[0073] (2), preparation of xerogel precursor

[0074] Move the nickel hydrogel obtained in step (1) into a refrigerato...

Embodiment 2

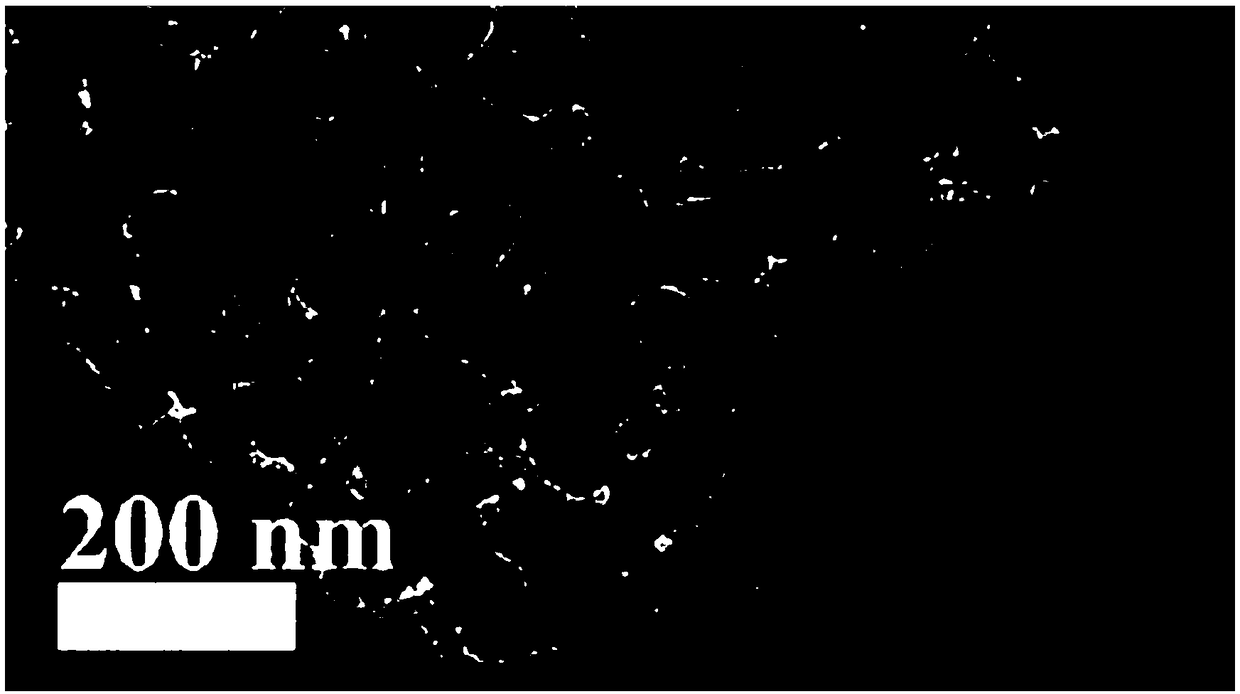

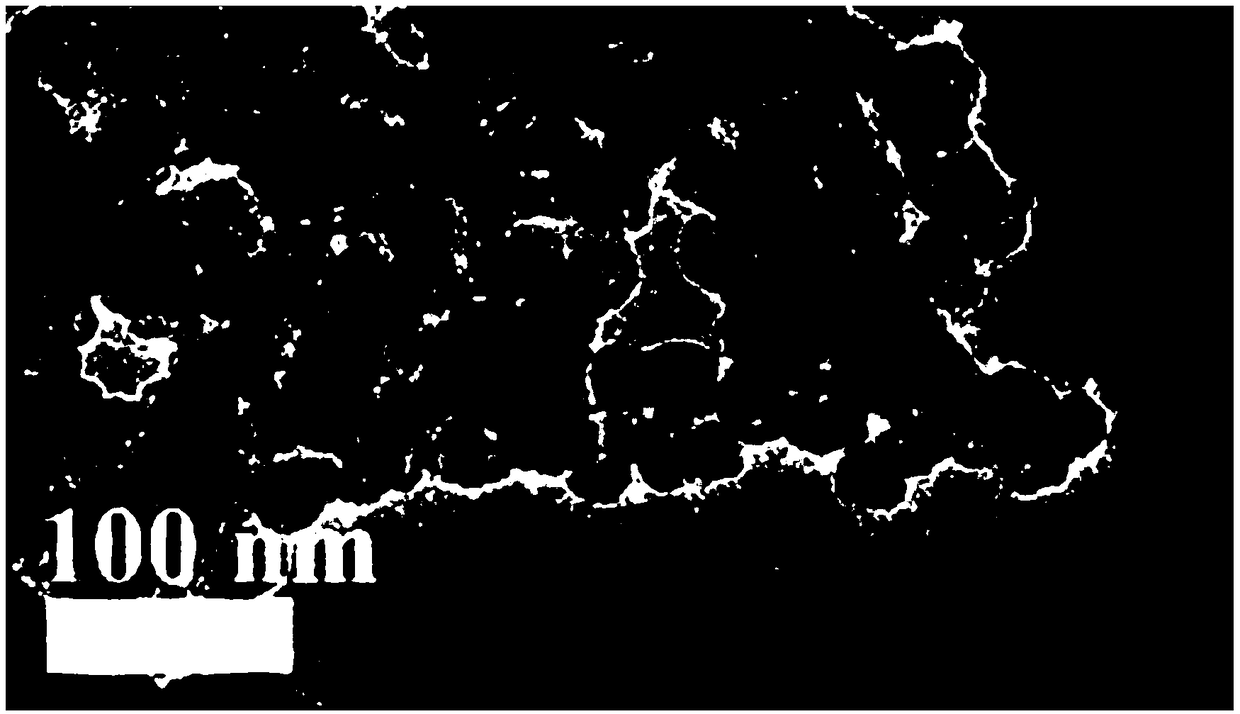

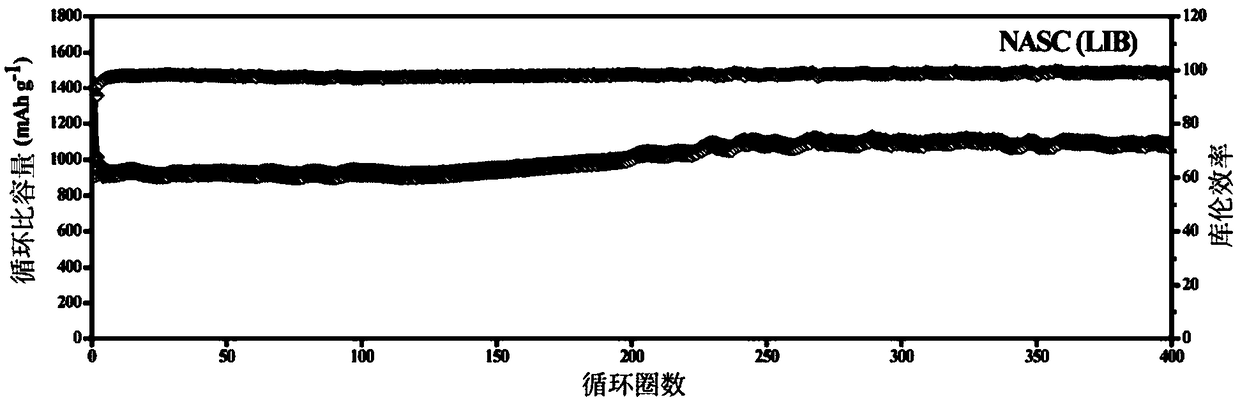

[0086] A high-cycle, high-rate carbon-based negative electrode energy storage composite material is prepared from three main elements, Ni, C, and O, by a method comprising the following steps:

[0087] (1), preparation of nickel hydrogel

[0088] Put 1g of polymer water-absorbent resin into the reaction vessel, then add 20ml of nickel salt solution, control the temperature at 45°C and shake in a constant temperature water bath for 8 hours to obtain nickel salt gel;

[0089] Described nickel salt aqueous solution, the nickel acetate aqueous solution that is about to join the nickel acetate crystal to obtain in distilled water is the nickel acetate aqueous solution of 0.025g / ml;

[0090] The amount of polymer resin and nickel salt solution is calculated by mass ratio, polymer resin: nickel acetate in nickel salt solution is 1:0.5;

[0091] The polymer water-absorbing resin is sodium polyacrylate;

[0092] (2), preparation of xerogel precursor

[0093] Move the nickel hydrogel...

Embodiment 3

[0102] A high-cycle, high-rate carbon-based negative electrode energy storage composite material is prepared from three main elements, Ni, C, and O, by a method comprising the following steps:

[0103] (1), preparation of nickel hydrogel

[0104] Put 1g of polymer water-absorbent resin into the reaction vessel, then add 20ml of nickel salt solution, control the temperature at 45°C and shake in a constant temperature water bath for 8 hours to obtain nickel salt gel;

[0105] Described nickel salt aqueous solution, the nickel acetate aqueous solution that is about to join the nickel acetate crystal to obtain in distilled water is the nickel acetate aqueous solution of 0.025g / ml;

[0106] The amount of polymer resin and nickel salt solution is calculated by mass ratio, polymer resin: nickel acetate in nickel salt solution is 1:0.5;

[0107] The polymer water-absorbing resin is sodium polyacrylate;

[0108] (2), preparation of xerogel precursor

[0109] Move the nickel hydrogel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com