Method for preparing self-supporting three-dimensional porous graphene composite microsphere

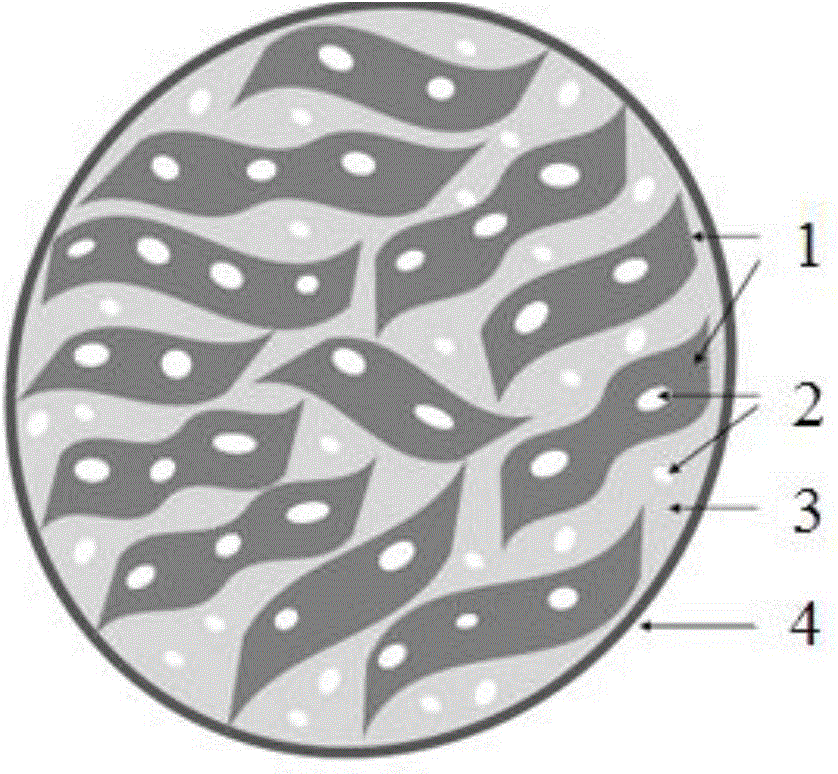

A graphene composite and three-dimensional porous technology, which is applied in the field of preparation of self-supporting three-dimensional porous graphene composite microspheres, can solve the problem of the inability to use negative electrode materials for sodium-ion batteries, less research and development of modified electrode materials, and the specific surface area of pure graphene. Large and other problems, to achieve the effect of reducing the first irreversible capacity, preventing agglomeration, and increasing the bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of graphite oxide is as follows:

[0032] Take an appropriate amount of concentrated H with a mass fraction of 95-98% 2 SO 4 Add to the reaction vessel placed in the ice bath, start stirring, and add graphite and KMnO at 20-100rpm 4 React for 30-60 minutes; then raise the temperature of the reaction solution to 40±2°C, react for 30-60 minutes; then control the temperature of the reaction solution at 95-100°C, add deionized water to the solution for 30-60 minutes; then add an appropriate amount H with a mass fraction of 5% 2 o 2 Finally, the reaction solution was filtered, and the filter residue was washed with 5% HCl until there was no SO in the filtrate. 4 2- (with BaC1 2 solution detection); then use deionized water to wash the filter residue to neutrality, and vacuum filter to obtain paste-like graphite oxide;

[0033] Among them, graphite is natural flake graphite or artificial graphite, with a particle size of 0.04-30 μm; concentrated ...

Embodiment 1

[0035] 1. Take 10g of graphite oxide, add it to 50mL of absolute ethanol, then add 0.3g of surfactant sodium dodecylbenzenesulfonate, ultrasonically treat at 45°C for 240min, then filter, and dry the filter residue at 60°C to obtain Graphene oxide; then put the graphene oxide into a microwave oven with a power of 800W and a frequency of 2.45GHz, and perform a heat treatment for 30min in an Ar gas atmosphere to obtain graphene;

[0036] 2. Take 8g of graphene obtained in step 1, add 20mL of deionized water, stir evenly, then add 32g of activator NaOH and 1.6g of binder starch, stir to form a slurry, and then the inlet temperature is 150 ° C, the outlet temperature spray drying and granulation under the conditions of 90°C, spray pressure of 2MPa, and nozzle diameter of 0.4mm, to obtain micron-sized graphene microspheres containing activators;

[0037] 3. Dissolve 1g of petroleum pitch in 10mL of kerosene, then add 10g of graphene microspheres containing activator obtained in ste...

Embodiment 2

[0041] 1. Take 10g of graphite oxide, add it to 100mL of absolute ethanol, then add 0.15g of surfactant sodium lauryl sulfate, ultrasonically treat at 30°C for 150min, then filter, and dry the filter residue at 70°C to obtain graphite oxide Then put the graphene oxide into a microwave oven with a power of 600W and a frequency of 2.45GHz, and perform a 16min heat treatment in an Ar gas atmosphere to obtain graphene;

[0042] 2. Take 6g of graphene obtained in step 1, add 10mL of deionized water, stir evenly, then add 13g of activator KOH and 0.8g of binder glucose, stir to form a slurry, and then the inlet temperature is 130 ° C, the outlet temperature 80°C, spray pressure of 0.5MPa, and nozzle diameter of 0.7mm for spray drying and granulation to obtain micron-sized graphene microspheres containing activators;

[0043] 3. Dissolve 1g of petroleum pitch in 8mL of kerosene, then add 5g of graphene microspheres containing activator obtained in step 2, stir at 70rpm until evenly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com