Patents

Literature

69results about How to "Adjust ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

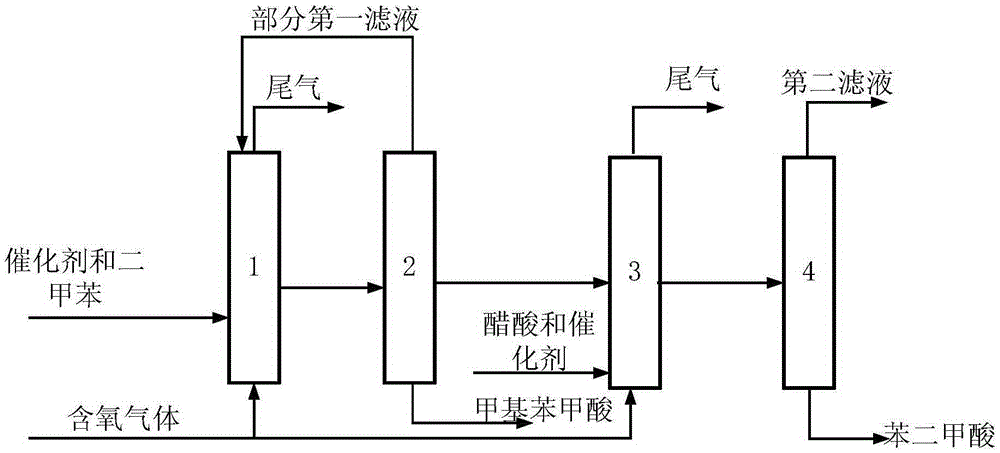

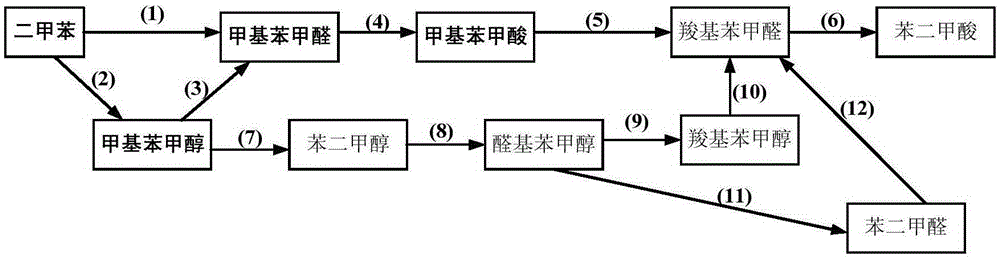

Co-production method for methyl benzoic acid and phthalic acid

ActiveCN105348067AHigh activityRealize online in-situ generationOrganic compound preparationCarboxylic compound preparationBenzoic acidAcetic acid

The invention discloses a co-production method for methyl benzoic acid and phthalic acid. The co-production method comprises the following steps: (1) continuously introducing fresh dimethylbenzene, a catalyst and oxygen-containing gas into a primary oxidation reactor for a reaction to obtain a primary oxidation reaction solution containing methyl benzoic acid and an eight-carbon oxygen-contained compound; (2) carrying out continuous cooling, crystallization and filtration on the primary oxidation reaction solution to obtain filter liquor and filter cake, circulating 1-98% of the filter liquor back the primary oxidation reactor continuously, and continuous rectifying the filter cake continuously, to obtain a low-boiling point front cut fraction, distillation raffinate and a methyl benzoic acid product separately; (3) adding the remaining filter liquor in the step (2) and the obtained front cut fraction and distillation raffinate in the step (2) into a secondary oxidation reactor continuously, and meanwhile continuously introducing a Co / Mn / Br catalyst, acetic acid and oxygen-containing gas into the secondary oxidation reactor for an oxidation reaction to obtain a secondary oxidation reaction mixture; and (4) continuously cooling, crystallizing and filtrating the secondary oxidation reaction mixture to obtain a filter liquor and a phthalic acid product. The co-production method has advantages of a simple process, a low cost, a high yield, good selectivity, good economic benefits, and environmental protection.

Owner:山东友道化学有限公司

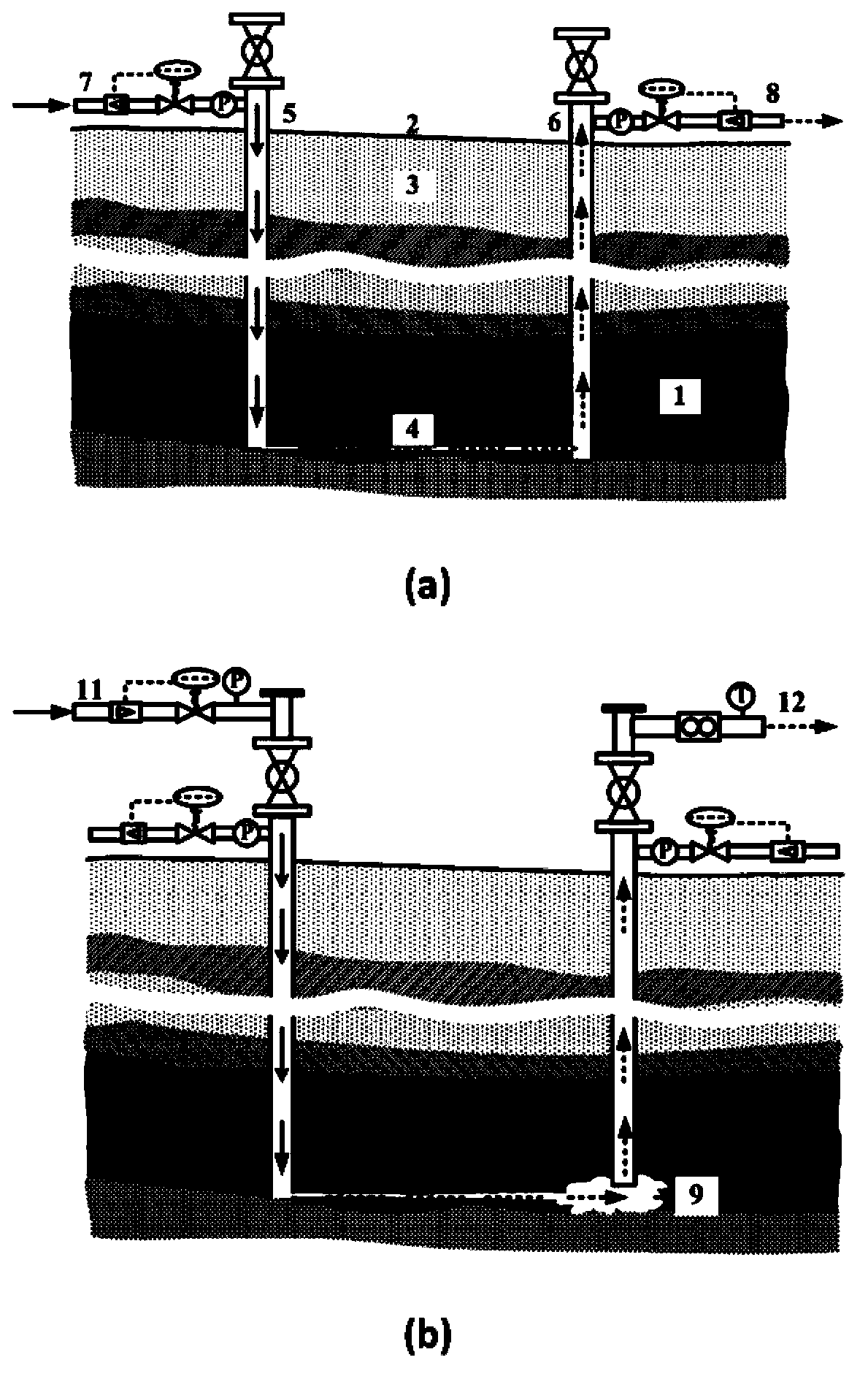

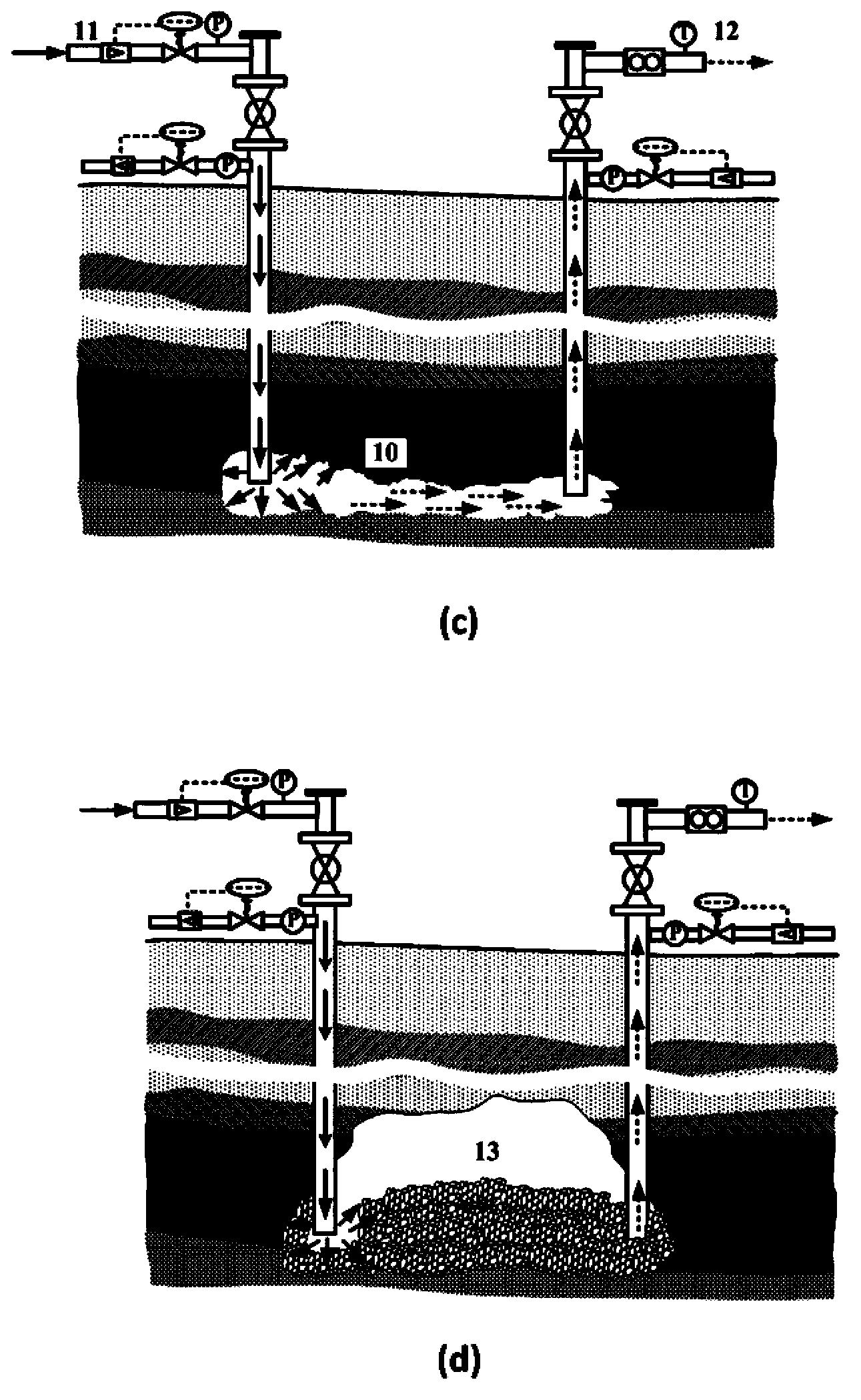

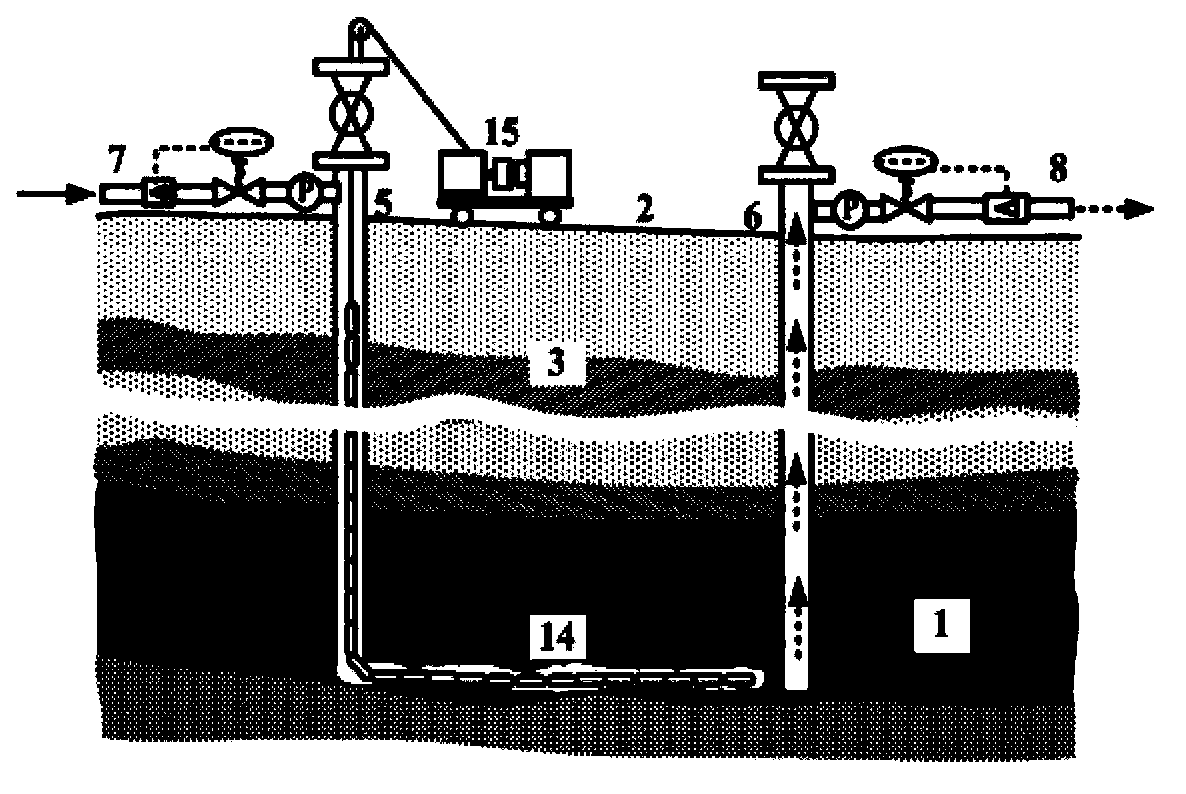

Method for crack communication, channel processing and underground gasification of underground mineral contained organic carbon reservoir

ActiveCN103670357AHigh calorific valueReduce manufacturing costSurveyConstructionsGas compositionResource utilization

The invention relates to a method for crack communication, channel processing and underground gasification of an underground mineral contained organic carbon reservoir. According to the method, a mixture of CO2 and O2 serves as a medium of a crack communication step, a channel processing step and / or a gasification step during underground gasification. By means of the mixture of CO2 and O2, energy in the underground mineral contained organic carbon reservoir is developed and utilized. Compared with the traditional utilization pattern, such as underground mining, the energy utilization rate is greatly increased. Compared with the traditional underground gasification technology, a heat value of combustible gas is increased, effective gas composition is improved and regulated, generation of CO2 is inhibited, production cost of raw materials is reduced, and trapping and resource utilization of CO2 is achieved.

Owner:ENN SCI & TECH DEV

Seafood flavor seasoning capable of being used for brewing drink

InactiveCN103652774AAppropriate adjustment ratioAdjust ratioFood shearingFood ingredient functionsFlavorVegetable oil

A seafood flavor seasoning capable of being used for brewing a drink relates to the technical field of production of drink seasonings. The seafood flavor seasoning is characterized by comprising the following components in parts by weight: 0.3-0.8 part of aginomoto, 0.3-0.8 part of salt, 0.1-0.5 part of sugar, 1-3 parts of dextrin, 10-30 parts of starch, 10-30 parts of pure shrimp and shrimp meal, 0.2-1 part of green onion granules, 0.2-1 part of carrot granules, 0.2-1 part of onion granules, and 3-5 parts of vegetable oil. In the formula, the seafood flavor seasoning further comprises the following components in parts by weight: 1-2 parts of curcuma powder, 0.5-1 part of garlic powder, 1-3 parts of green tea powder, and 0.25-0.35 part of perilla oil. The seafood flavor seasoning breaks the situation of lack of salty and seafood flavor of the traditional drink, multiple seasoning materials are used to develop the seafood flavor drink seasoning, so that the product can be used for directly brewing a drink to meet the requirement of diversity of the drink flavors and the effects of tonifying spleen, promoting appetite, strengthening healthcare and nourishing are achieved.

Owner:JIESHOU ZHAOLONG FOOD

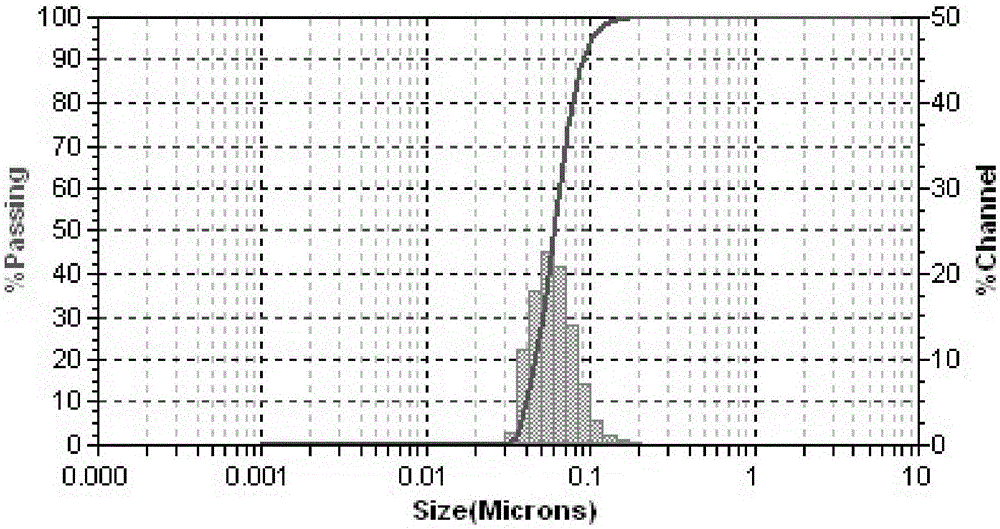

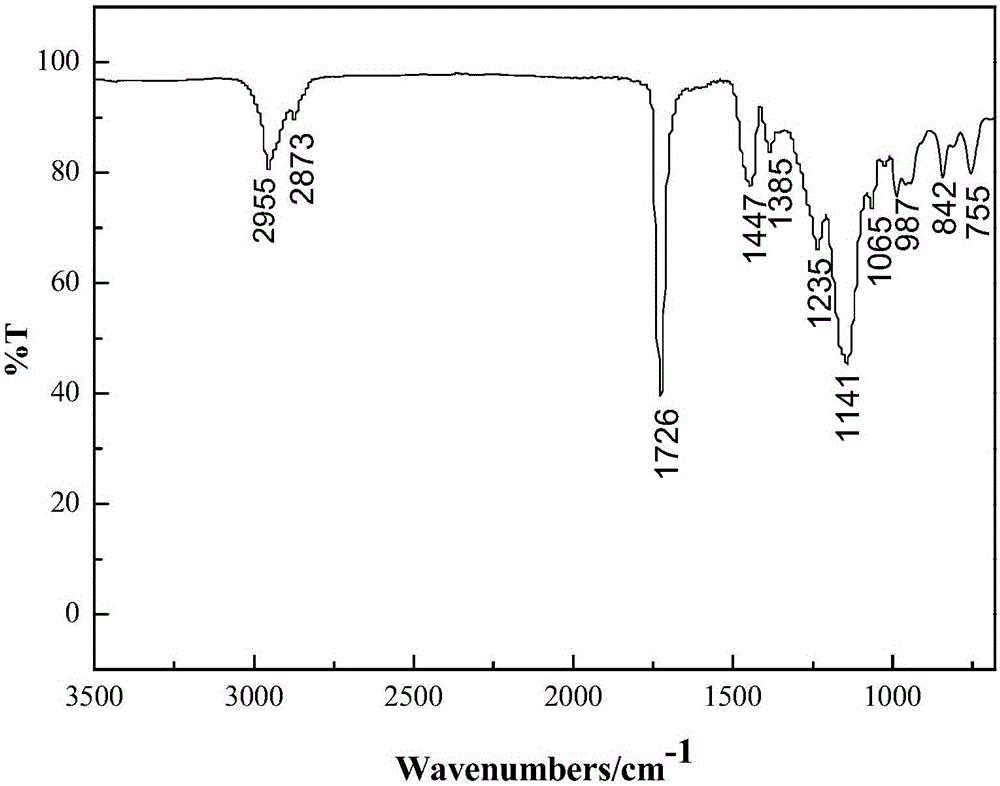

Environmentally-friendly cross-linked acrylate polymer emulsion and preparation method thereof

The invention relates to an environmentally-friendly cross-linked acrylate polymer emulsion and a preparation method thereof. The emulsion consists of six main components through semicontinuous seeded emulsion polymerization, is fine and smooth in appearance and is a blue-fluorescent semitransparent emulsion, a pH value is 7.5+ / -0.5, the solid content is 30-50%, the emulsion particle diameter is 50-100 nanometers, and the polymer emulsion has good film-forming property and adhesion after film forming at the 80 DEG C temperature. The environmentally-friendly cross-linked acrylate polymer emulsion has the advantages that due to the fact that an amino acid based anionic surface active agent and an alkyl polyglucoside non-ionic surface active agent both have excellent biodegradability and environmental protection effect and are used for replacing commonly-used alkylphenol polyoxyethylene ether and an alkylbenzene sulfonate surface active agent having poor biodegradability, the environmentally-friendly cross-linked acrylate polymer emulsion is more environmentally-friendly, and the demand for the performances of the emulsion is met.

Owner:新东方油墨有限公司

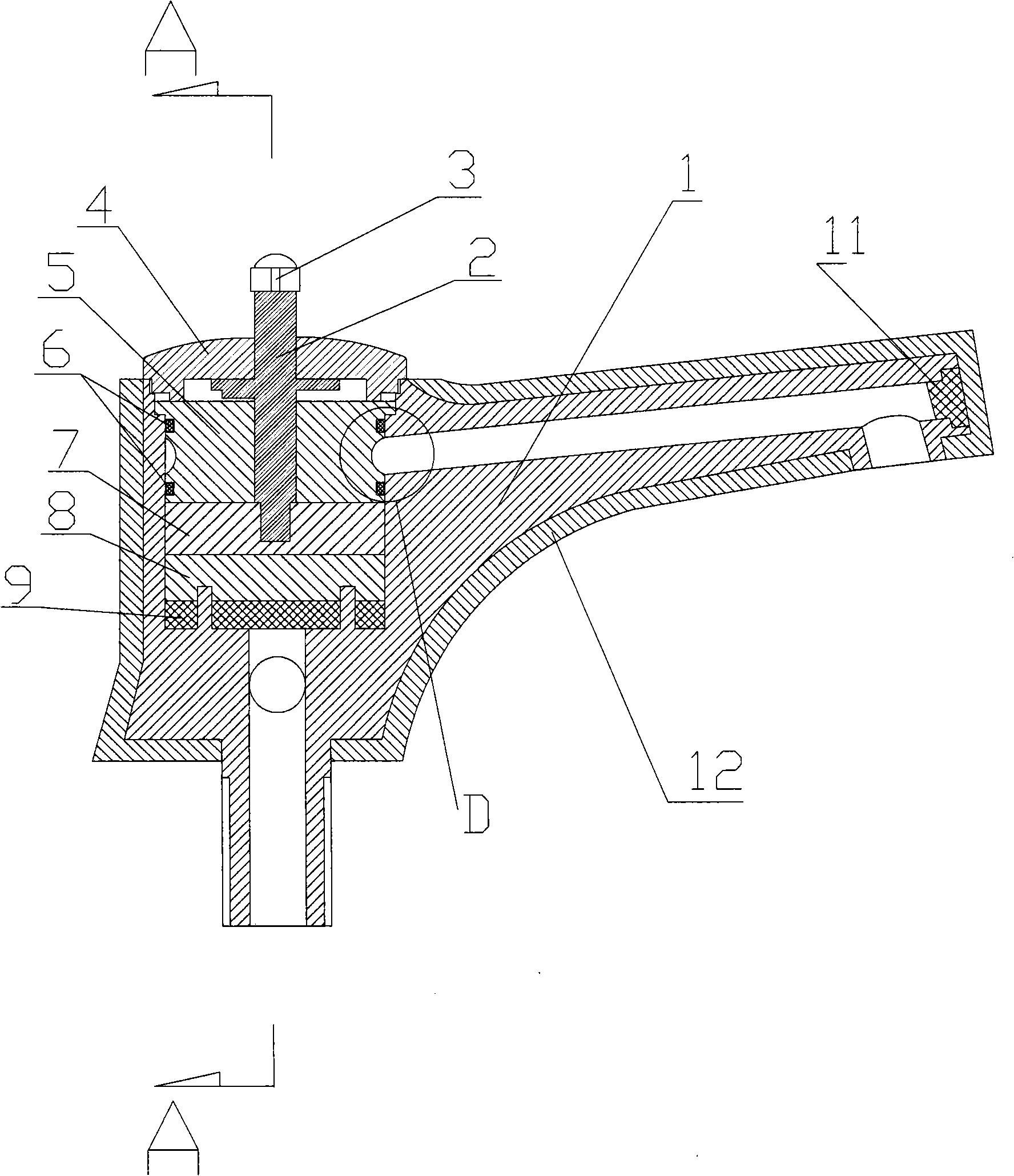

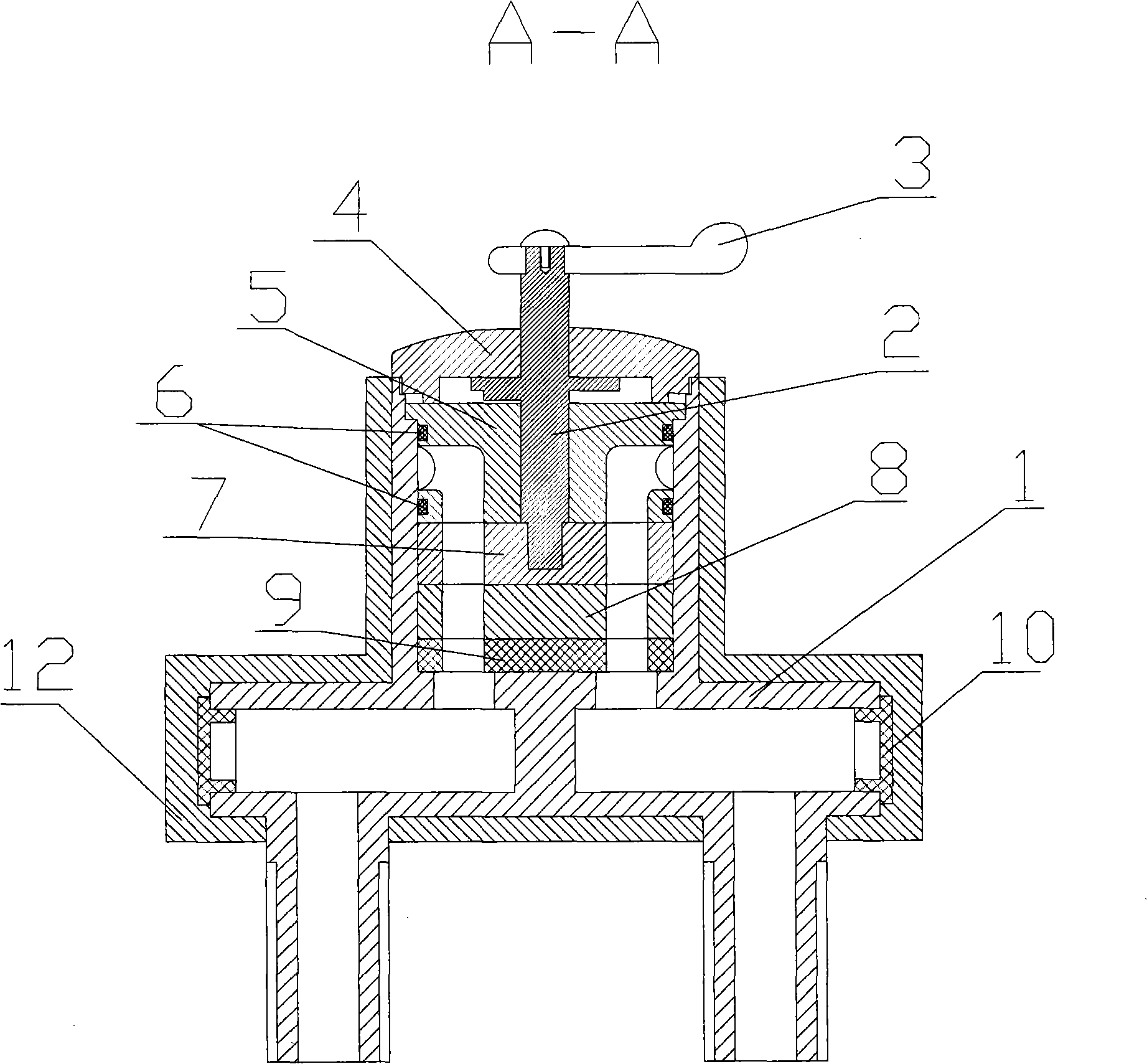

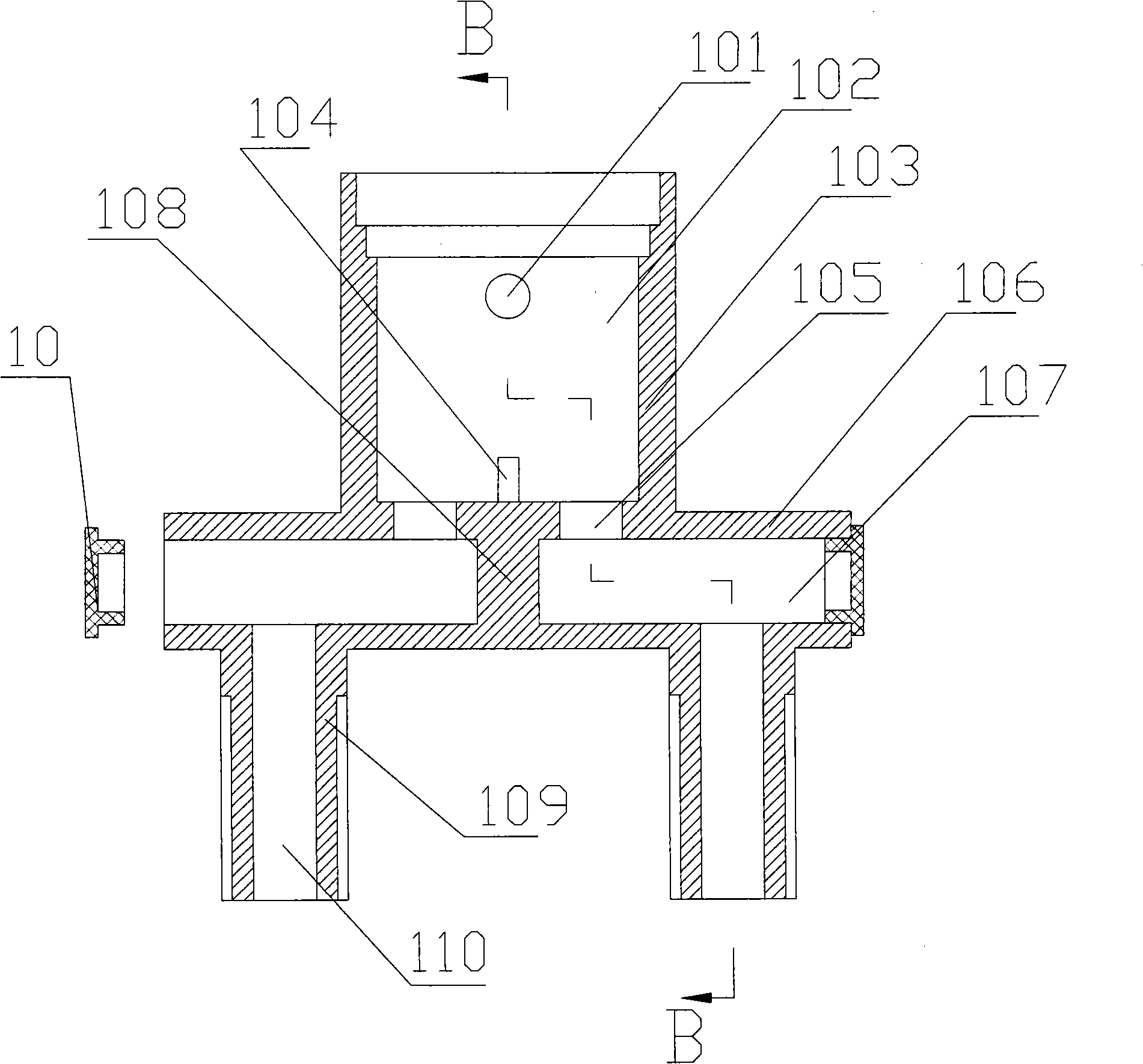

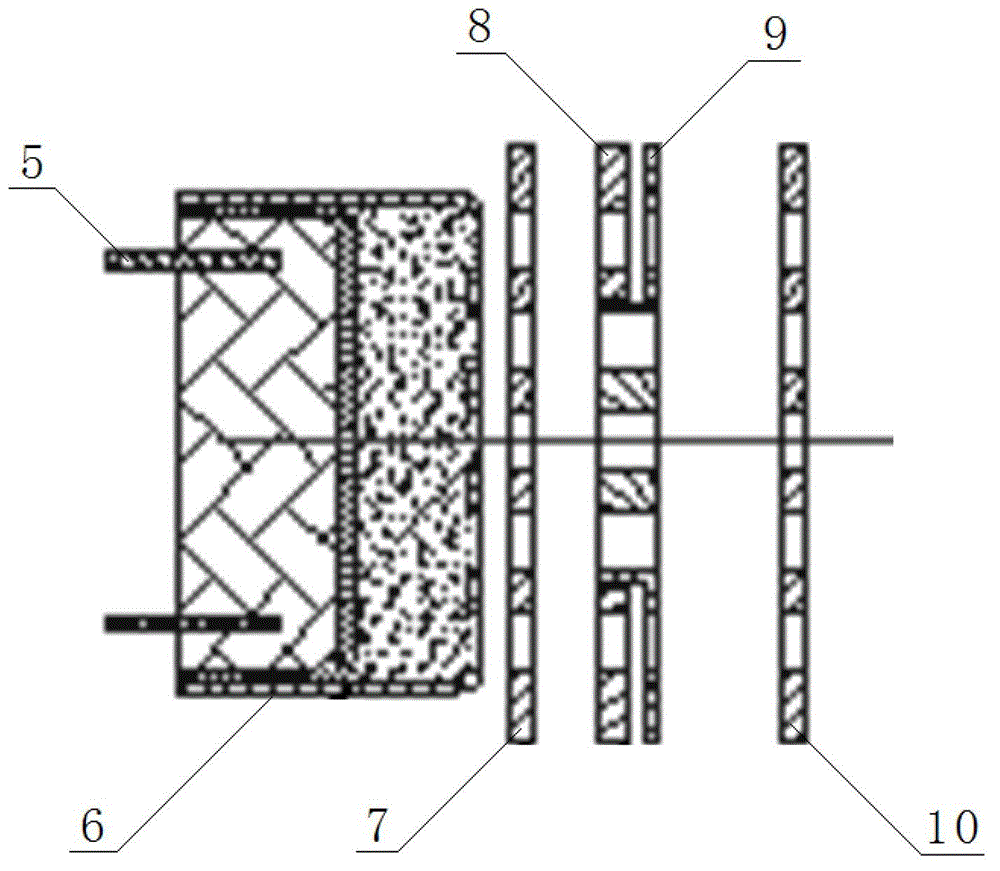

Double-temperature water-heating series two injection type concurrent control valve and manufacturing method thereof

InactiveCN101270827AHigh temperature control sensitivityLow costOperating means/releasing devices for valvesMultiple way valvesCushionMetallic materials

A downstream control valve of two-pouring type of dual-temperature water heating series and a manufacture method thereof are provided. The invention includes a one-step forming valve body, a valve rod, a spiral handle, a valve cover, a valve core and a post forming valve body. The one-step forming valve body is formed in a first-time die by injection molding. A blank cap and a closure head are arranged on the one-step forming valve body and then the one-step forming valve body is placed in a second-time die chamber to form the post forming valve body which wraps the one-step forming valve body. The valve rod, the spiral handle and the valve cover are mounted on the forming valve body. The upper sheet of the valve core, the middle sheet of the valve core, the bottom sheet of the valve core and the cushion of the valve core are mounted in turn in the spool chamber of the forming valve body. In order to reduce the production cost of the prior water tap and improve the sanitary quality of the water, metal material is replaced by plastic and the through hole injection molding and the post forming technology are adopted. When the water tap is rotated left or right, the hot or the cold water can be provided. With the advantages of high sensitivity of temperature control and high service efficiency, the invention solves the problem of high cost for the prior water tap and has a broad market foreground.

Owner:赵雨欧

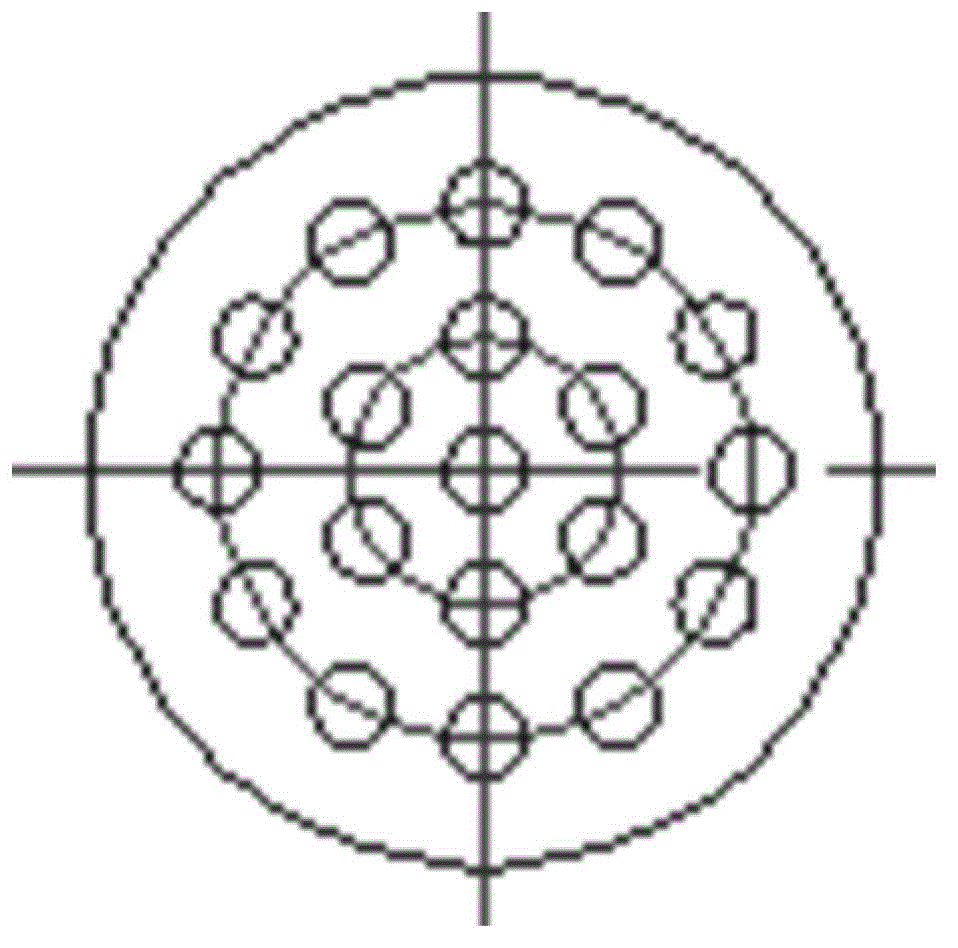

Dual-mode multi-beam electronic gun for dual-mode traveling wave tube and method for controlling dual-mode multi-beam electronic gun

ActiveCN102945781ASimple processConsistent launch trajectoryTransit-tube electron/ion gunsTransit-tube cathodesDual modeEngineering

The invention discloses a dual-mode multi-beam electronic gun for a dual-mode traveling wave tube and a method for controlling the dual-mode multi-beam electronic gun. The dual-mode multi-beam electronic gun comprises a cathode, a shade gate, an internal grid, an external grid and an anode, which are arranged in sequence, wherein the cathode comprises a cathode molybdenum tube, the inside of which is divided into two parts along the axis of the cathode molybdenum tube; the two parts are separated by insulating ceramic; a cathode sponge body is mounted in one part, and a filament filling and sealing insulator is mounted in the other part and is internally provided with a filament; the end face of the cathode molybdenum tube is provided with a plurality of holes; the internal grid controls the electronic beams in partial holes, and the external grid controls the electronic beams in the rest holes so as to implement dual-mode operation. According to the dual-mode multi-beam electronic gun and the method, a high-mode operation state and a low-mode operation state can be provided, and the control voltage is consistent, so that the electronic beams in two modes can be focused by the same magnetic field.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

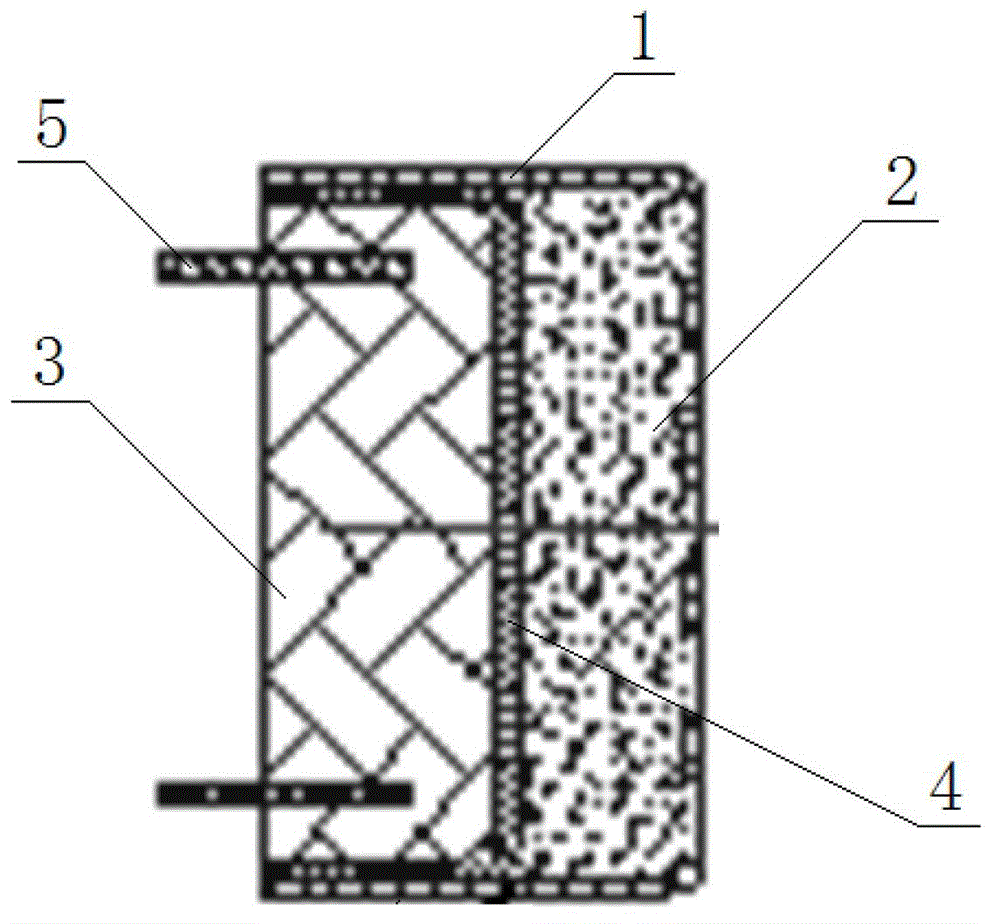

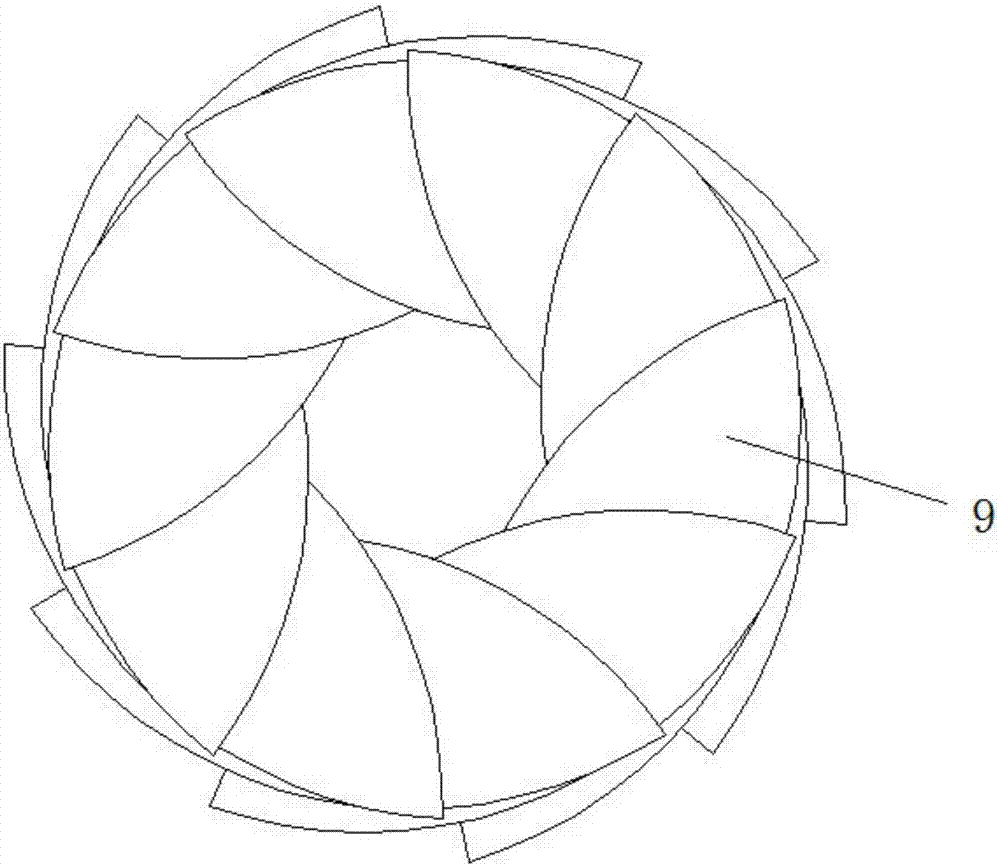

Stirring device for garden irrigation

PendingCN107537365AWell mixedRate regulationRotary stirring mixersMixer accessoriesArchitectural engineeringCard holder

The invention discloses a stirring device for garden irrigation. The stirring device comprises a device bracket, wherein a stirring cylinder is arranged at the inner wall of the bottom part of the device bracket; the inner wall of the bottom part of the stirring cylinder is provided with a cavity; a stirring motor is arranged in the cavity; an output shaft of the stirring motor is connected with astirring peddle; a raw material funnel is clamped into the top part of the device bracket; a fixed circular ring is fixedly arranged at the outer side of the bottom part of the raw material funnel; arotary ring is sheathed at the outer side of the fixed circular ring; the vertical inner wall of the rotary ring is provided with a circular side groove; a blade-shaped blocking plate is arranged inthe circular side groove, and a circular through hole is formed in the blade-shaped blocking plate in the vertical direction; the inner wall of the bottom part of the circular side groove is fixedly connected with a winding column; the winding column penetrates through the circular through hole; the blade-shaped blocking plate is provided with an arc-shaped slide groove, and the arc-shaped slide groove is glidingly connected with a slide column. The stirring device has the advantages that the stirring effect is better, the efficiency is higher, the ratio can be conveniently adjusted, and the use requirement of people in production and living is met.

Owner:赵寰

Method for regulating acid and alcohol proportions in anaerobic gas-absorbing microorganism fermentation products

ActiveCN105177058AHigh technical valueEffective adjustment ratioBiofuelsFermentationBiologyCulture mediums

The invention aims to provide a culture method for regulating acid and alcohol proportions in anaerobic gas-absorbing microorganism fermentation products. The method is capable of regulating the acid and alcohol proportions in the fermentation products by changing culture conditions. Particularly, the method is capable of regulating the alcohol substance proportion in the fermentation products in a shaking culture system by changing culture medium conditions. The method for increasing the alcohol substance proportion in the anaerobic gas-absorbing microorganism fermentation products is implemented by regulating an initial pH (potential of hydrogen) value and mes concentration of the system, wherein the high initial pH value and the low mes concentration can increase the acid substance proportion in the fermentation products remarkably; the slightly low initial pH value and the slightly low mes concentration can increase the alcohol substance proportion in the fermentation products remarkably.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

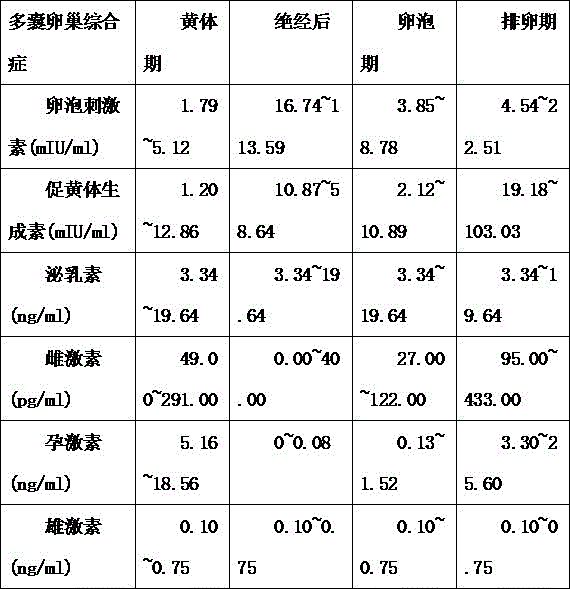

Traditional Chinese medicine composition and preparation for treating female sterility and application

InactiveCN105687927AAdjust ratioQuality improvementDispersion deliveryMammal material medical ingredientsAngelica Sinensis RootAnovulation

The invention discloses a traditional Chinese medicine composition for treating female sterility to solve the problems of menstrual disorder and anovulation caused by a polycystic ovarian syndrome, a premature ovarian failure and the like. The traditional Chinese medicine composition for treating female sterility is prepared from rhizoma pinelliae, ginseng, malt, radix astragali, fructus rubi, fructus psoraleae, herba epimedii, common curculigo rhizomes, herba cistanches, antlers, human placenta, coix seeds, rhizoma cyperi, radix rehmanniae preparata, Chinese yam, fructus corni, semen cuscutae, radix angelica sinensis, fructus lycii, glossy privet fruits, herba ecliptae and cortex cinnamomi.

Owner:刘盛勇

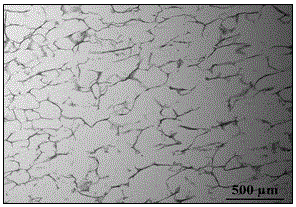

Nucleus pulposus-cartilage extracellular matrix scaffold and preparing method thereof

InactiveCN105031734AOvercome the disadvantages of small quantities and difficult accessGood biocompatibilityProsthesisArticular surfacesArticular surface

The invention discloses a nucleus pulposus-cartilage extracellular matrix scaffold and a preparing method thereof and belongs to the biological tissue engineering technology. The preparing method comprises the steps that nucleus pulposuses and bony articular surface cartilage are smashed, decellularized, subjected to gradient centrifugation to collect extracellular matrix microfilament suspension, and freeze-dried to obtain a freeze-dried decellularized nucleus pulposus matrix and a freeze-dried decellularized cartilage matrix, the two matrixes are taken in certain proportion and dissolved in ultrapure water to prepare mixed matrix suspension with certain concentration, and the mixed matrix suspension is freeze-dried and subjected to ultraviolet irradiation crosslinking and chemical reagent crosslinking in sequence so that the nucleus pulposus-cartilage extracellular matrix scaffold can be obtained. In this way, the defect that the nucleus pulposuses are hard to obtain due to the small number is overcome; the preparing technology is simple, and decellularizing can be achieved thoroughly; the matrix scaffold is degradable and high in biocompatibility; the matrix scaffold is of a three-dimensional structure, is high in mechanical property and plasticity, and can facilitate the distribution, growth and differentiation of seed cells; the freeze-dried extracellular matrixes are convenient to store and prepare and can be used for constructing a tissue engineered intervertebral disc to repair partial defects of the intervertebral disc, and broad clinical application prospects are realized.

Owner:TIANJIN HOSPITAL

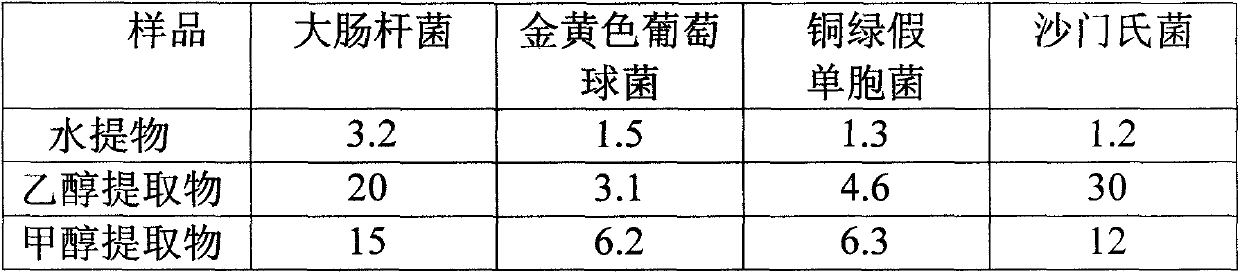

Walnut green husk feed additive and preparation method thereof

InactiveCN107549465AAdjust ratioReduce dosageFood processingAnimal feeding stuffAnimal scienceAntibiotic Y

The invention relates to the field of feed production and discloses a walnut green husk feed additive and a preparation method thereof. Multiple extraction methods such as a water extraction method, an ethanol extraction method and a methanol extraction method are adopted to extract walnut green husks to serve as the feed additive. The walnut green husk feed additive can replace antibiotics and antiviral drugs in feed or reduce the dosages of antibiotics and antiviral drugs in feed, and achieves the purposes of inhibiting proliferation of common pathogenic bacteria and viruses of livestock andpoultry, regulating the proportion of the intestinal flora, preventing infectious diseases and increasing the survival rate. The feed additive can be applied to poultry feed and livestock feed.

Owner:XIHUA UNIV

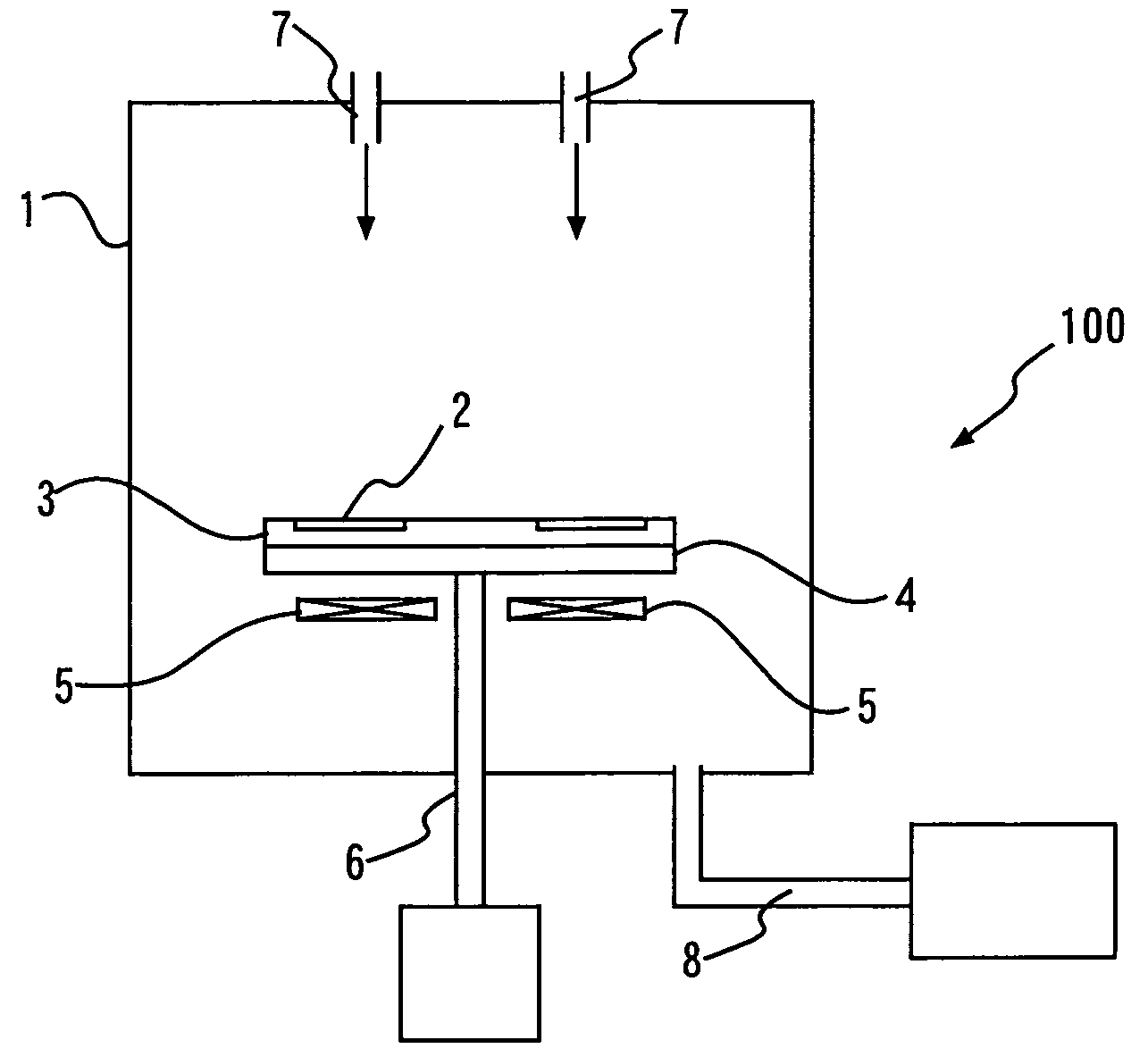

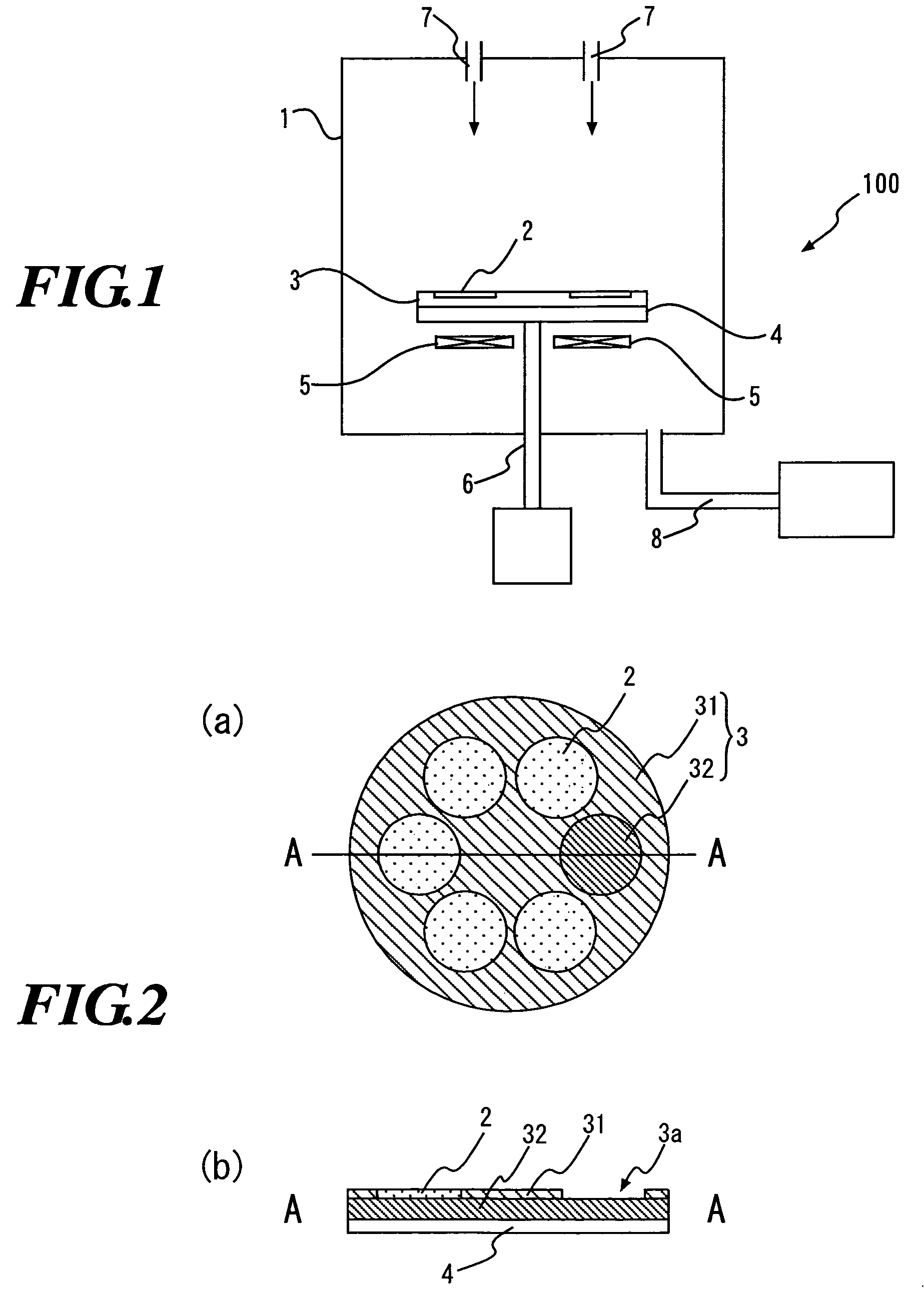

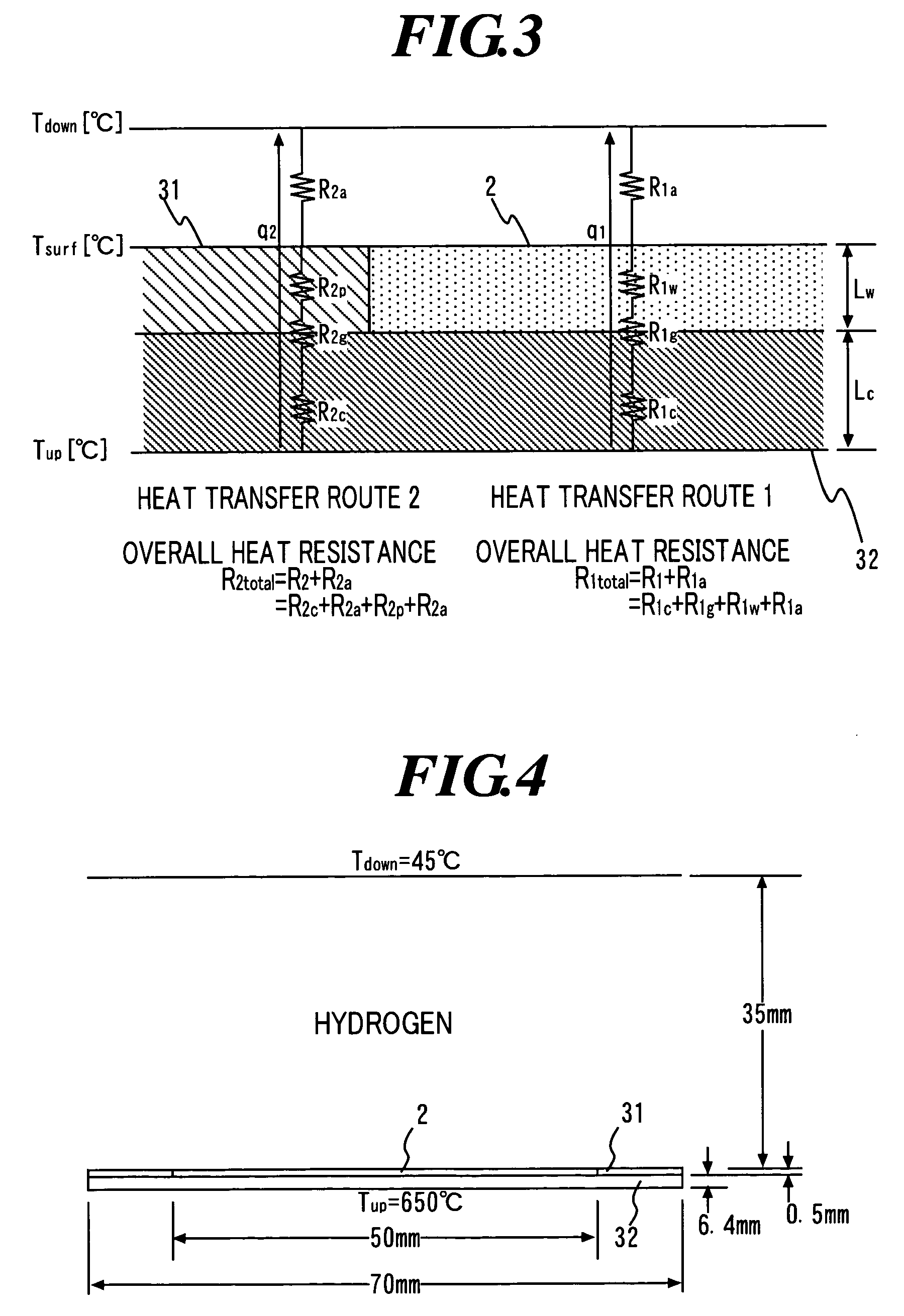

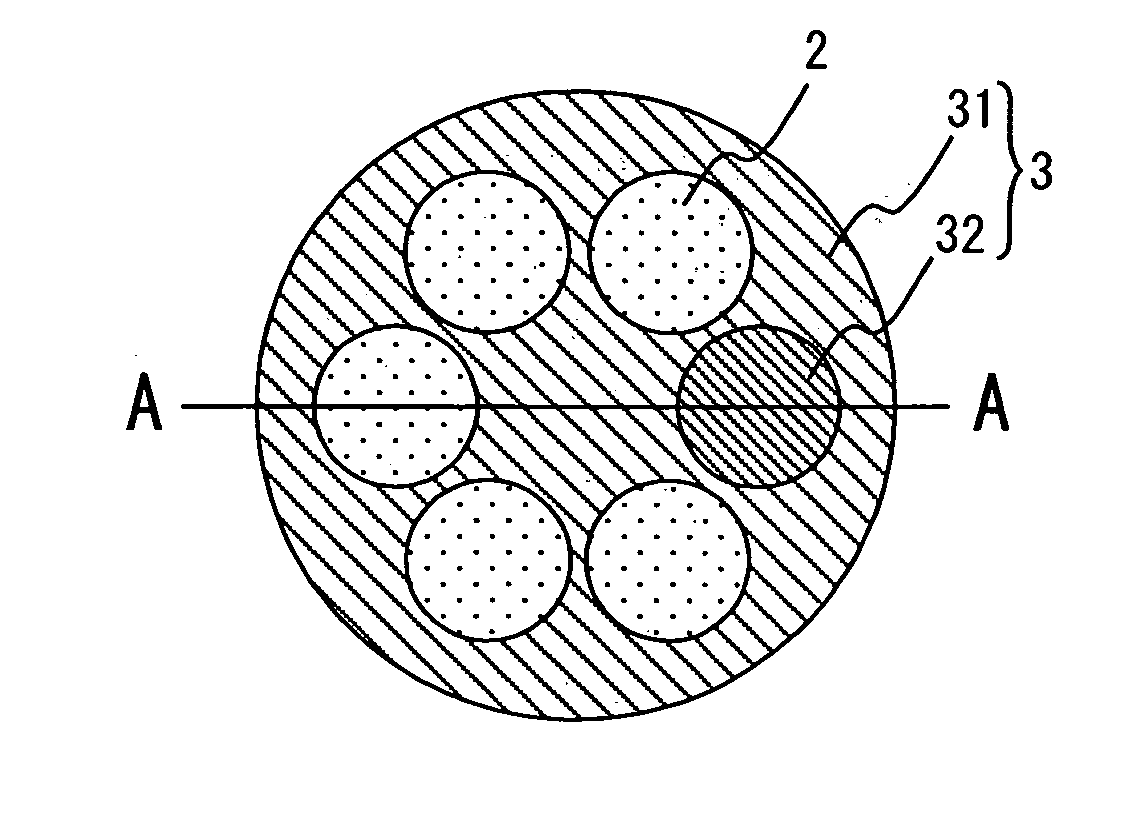

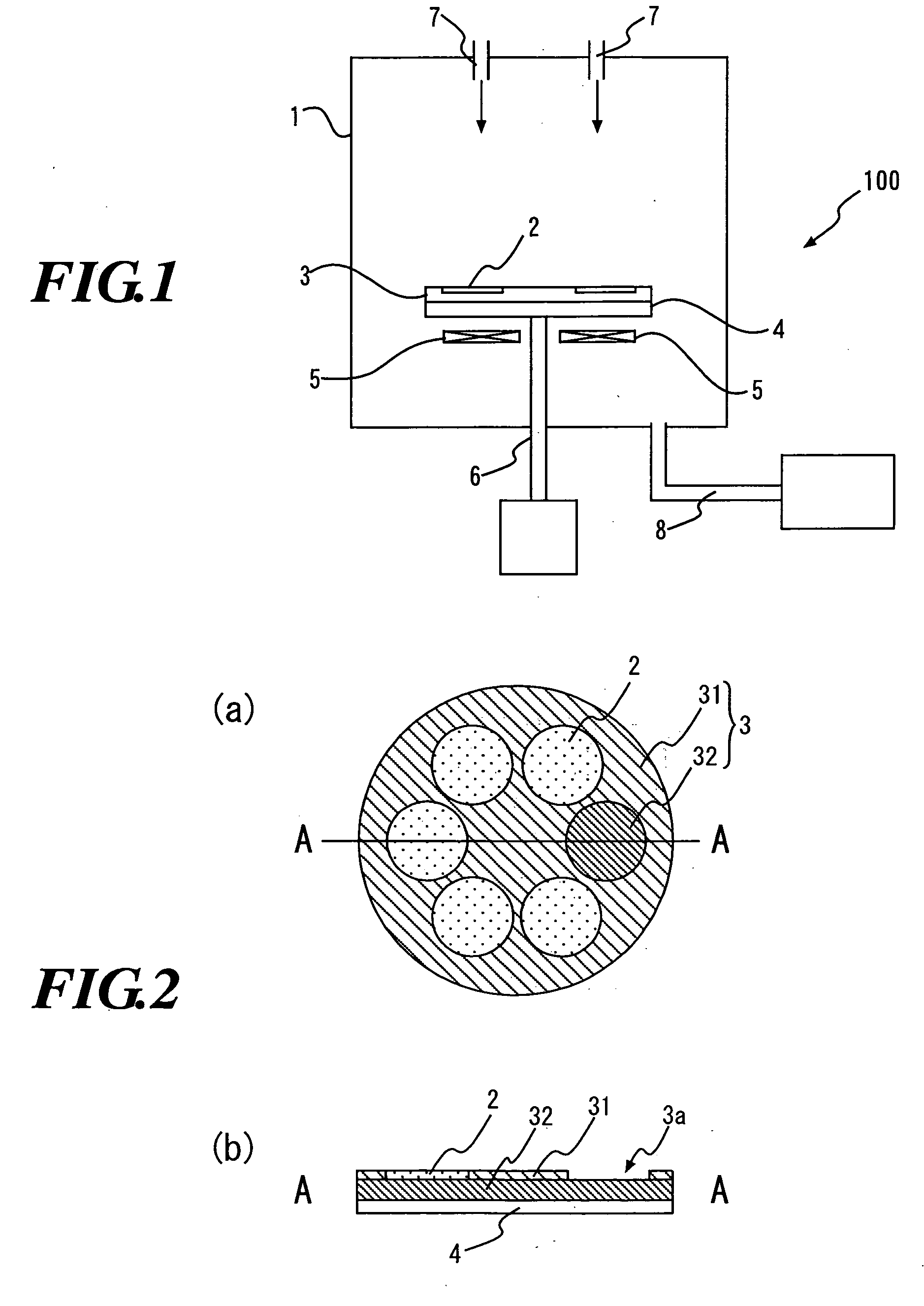

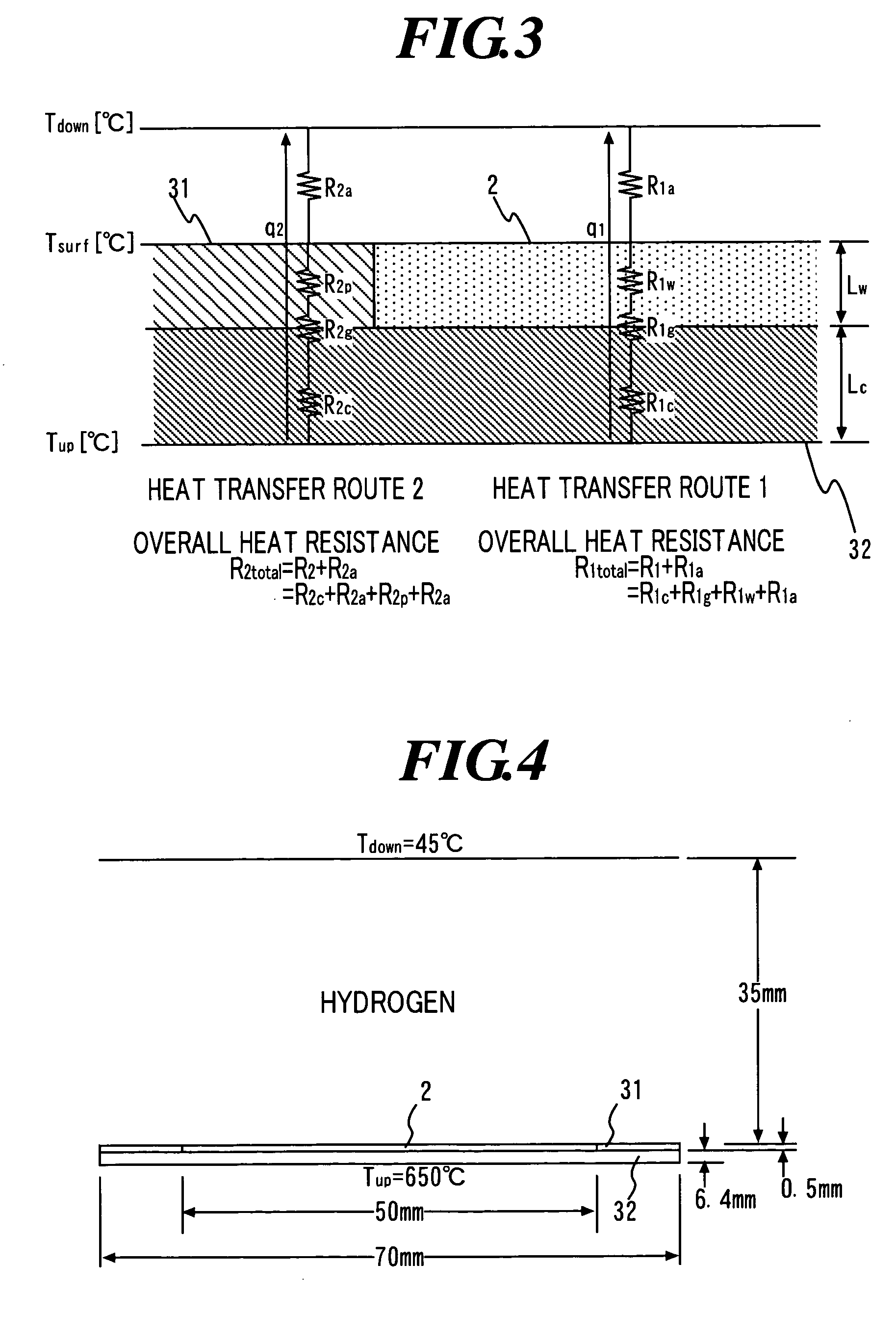

Vapor-phase epitaxial apparatus and vapor phase epitaxial method

InactiveUS7314519B2Adjust ratioUniform heat resistanceAfter-treatment apparatusPolycrystalline material growthHeat flowGrown film

A vapor-phase growth apparatus including a reaction furnace, a wafer container disposed in said furnace, a gas supply member, and a heating member, wherein the apparatus is designed to form a grown film on a front surface of the wafer by supplying a source gas in a high temperature state while the heating member heats the wafer in the reaction furnace through the wafer container. The wafer container includes a heat flow control section having a space for disposing a wafer; and a heat flow transmitting section joined to the heat flow control section. The contact heat resistance Rg between the heat flow control section and the heat flow transmitting section is not less than 1.0×10−6 m2K / W to not more than 5.0×10−3 m2K / W. The heat flow control section is made of a material having a coefficient of thermal conductivity 5 to 20 times that of the wafer.

Owner:JX NIPPON MINING & METALS CORP

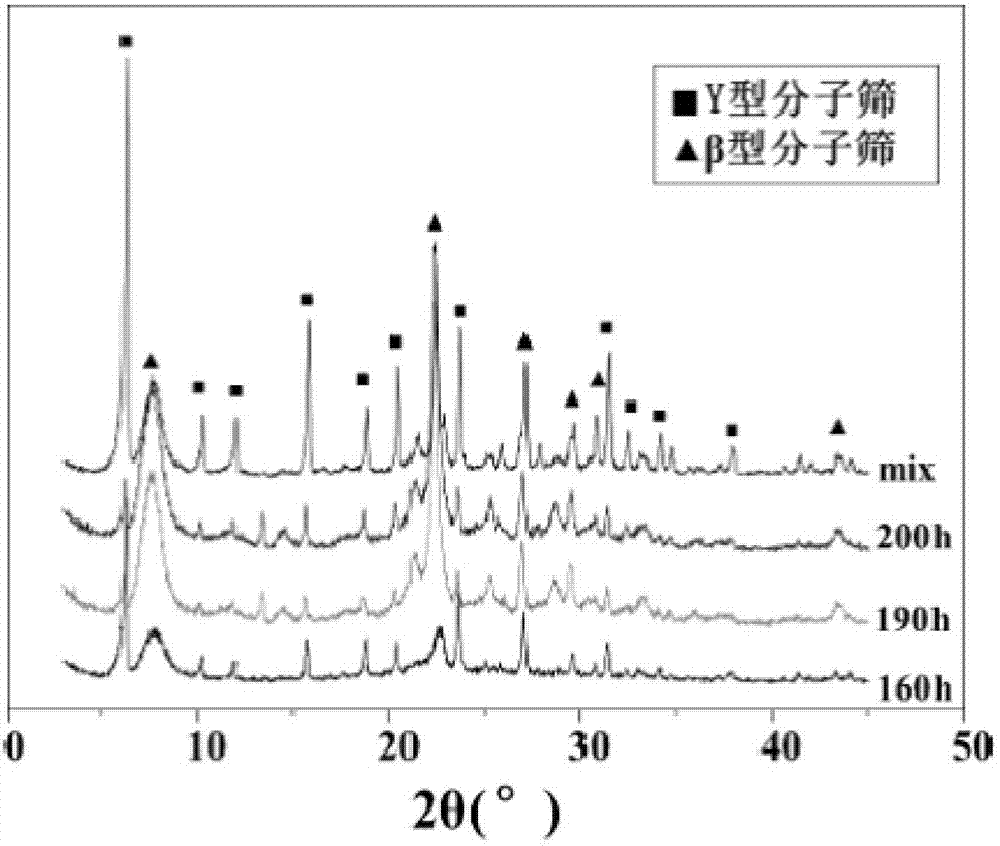

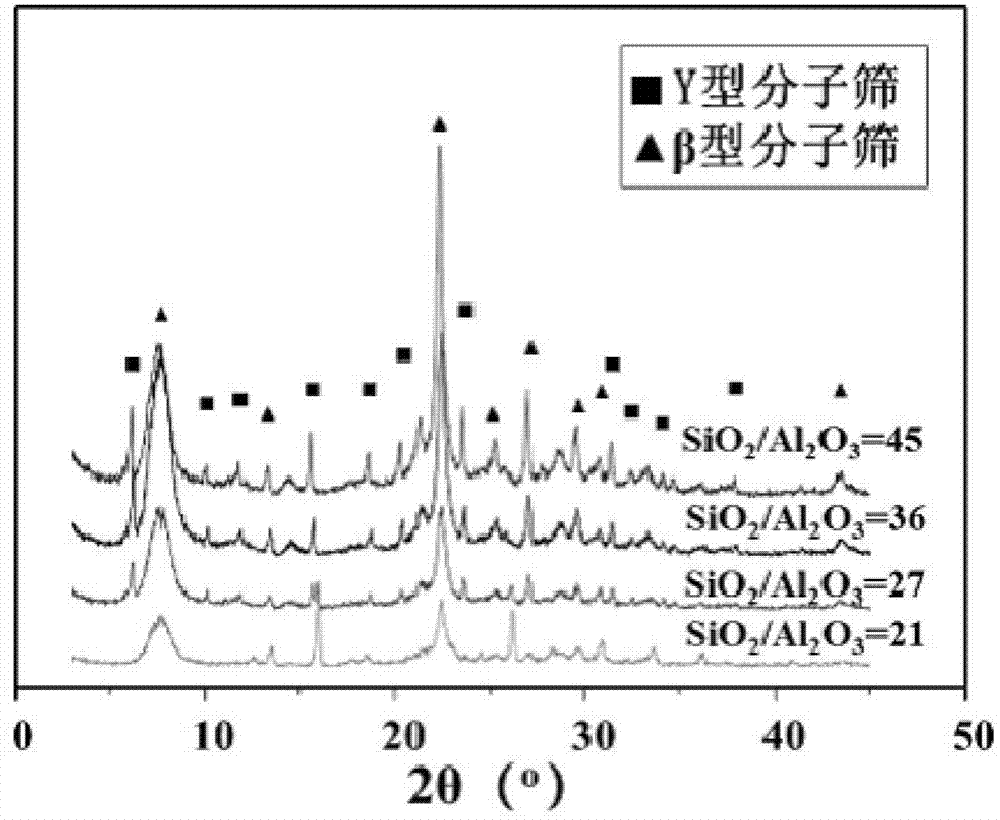

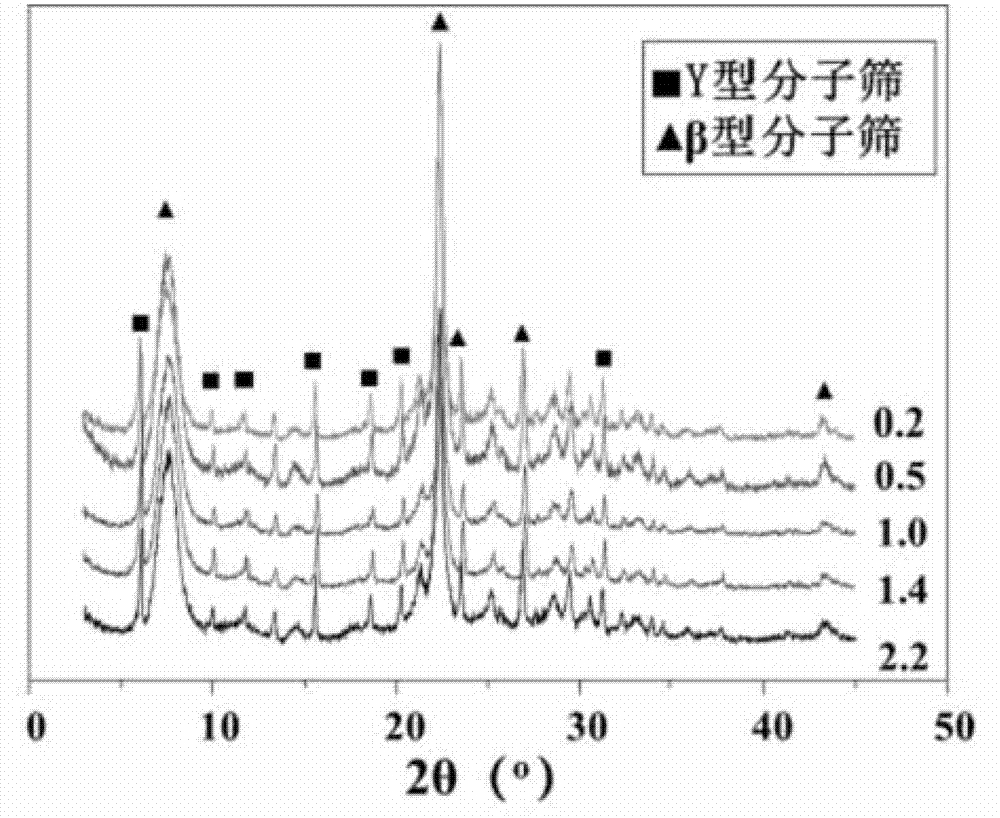

Copper-composite molecular sieve catalyst used for synthesis of diethyl carbonate through gas-phase oxidative carbonylation and its preparation method

ActiveCN102814193AAdjust ratioStable structureMolecular sieve catalystsOrganic compound preparationMolecular sieveGas phase

The invention discloses a catalyst used for synthesis of diethyl carbonate through ethanol gas-phase carbonylation and its preparation method. A composite molecular sieve Ybeta is adopted to prepare a copper-composite molecular sieve catalyst through a solid ion exchange method, and the catalyst is applied in a reaction system for synthesis of diethyl carbonate through oxidative carbonylation. The unique acidity and pore structure of the composite molecular sieve are utilized to improve the catalyst performance. The catalyst prepared by the method has the advantages of high selectivity, long service life, low preparation cost, and relatively simple process.

Owner:TIANJIN UNIV +1

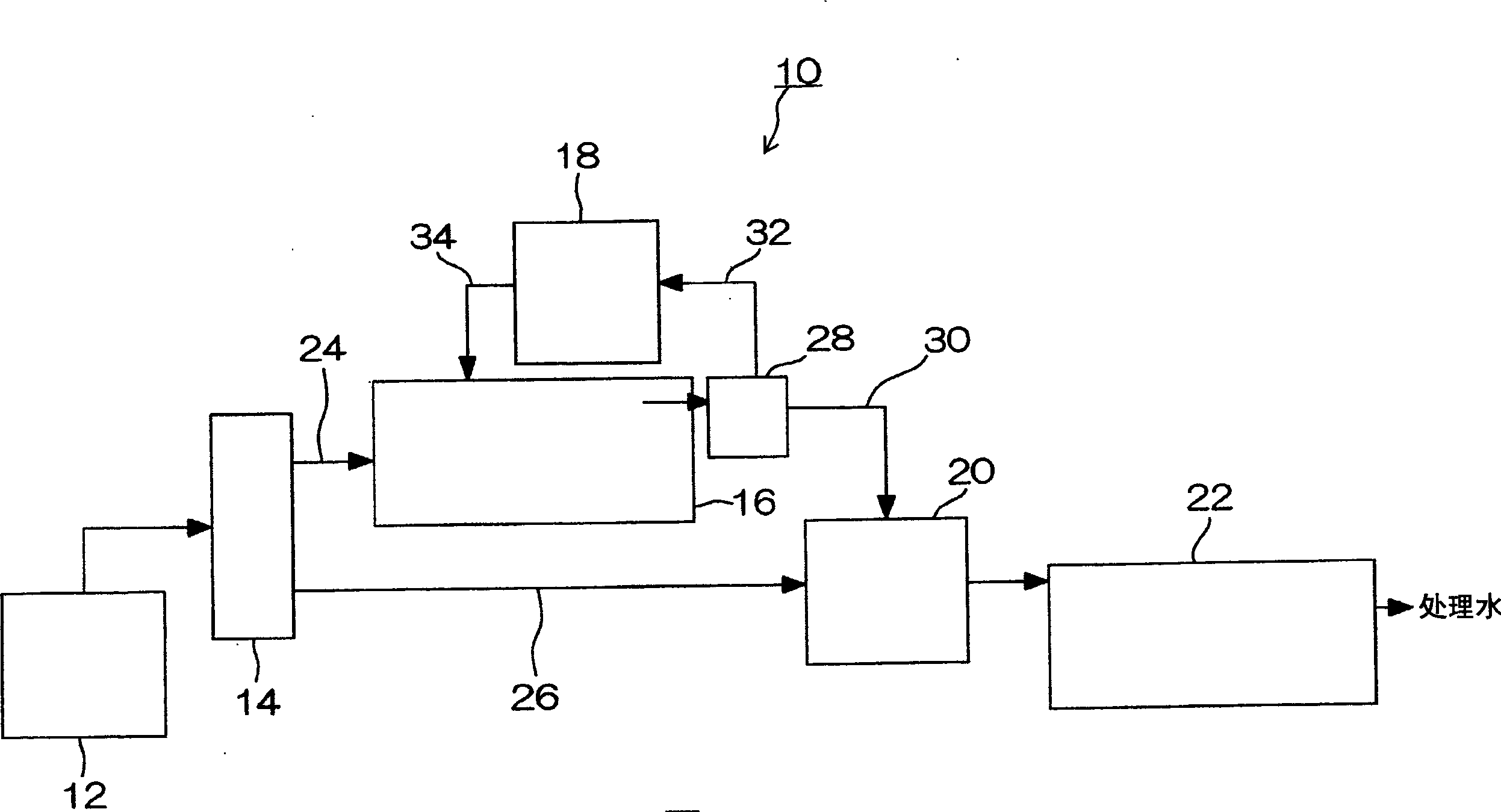

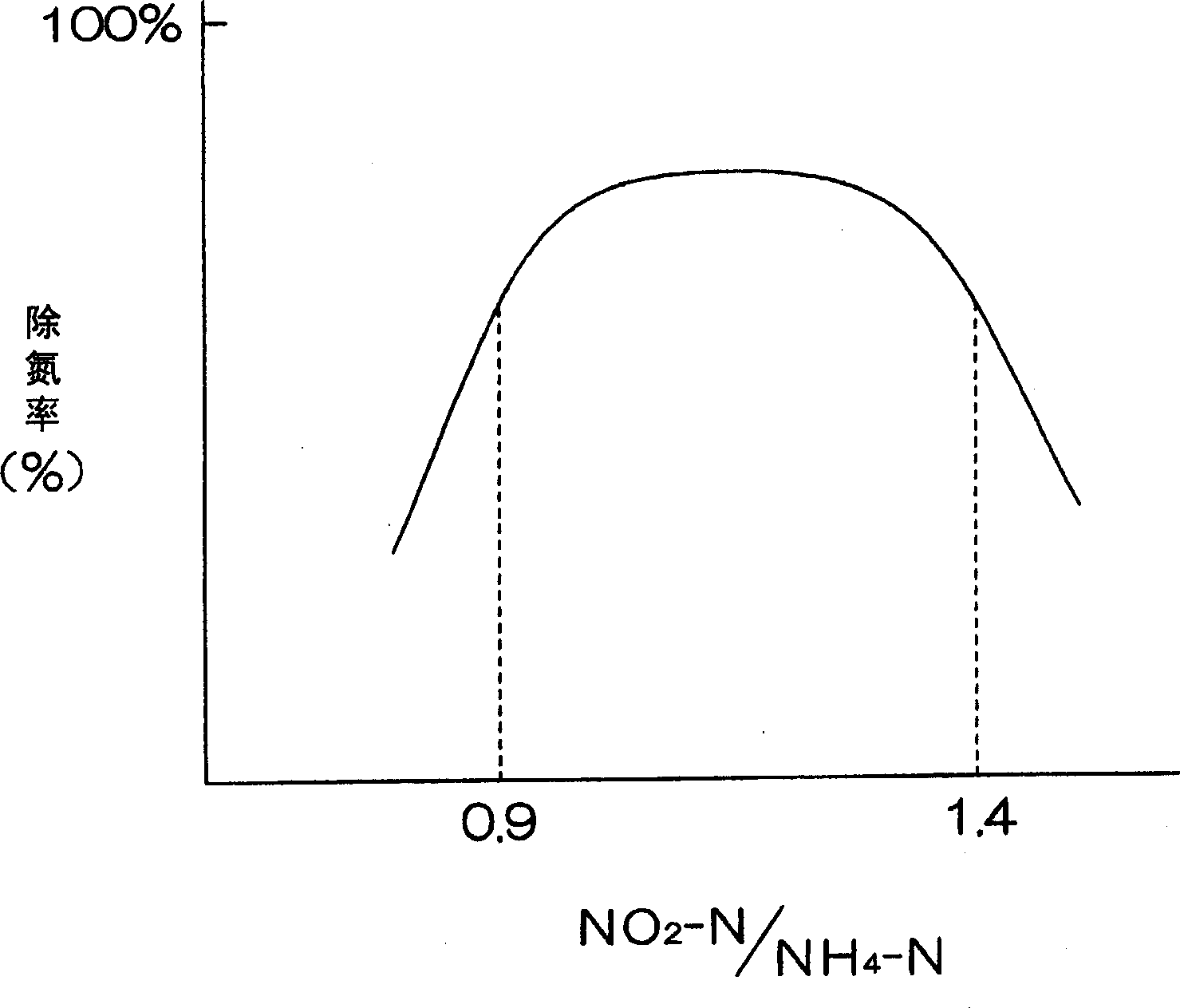

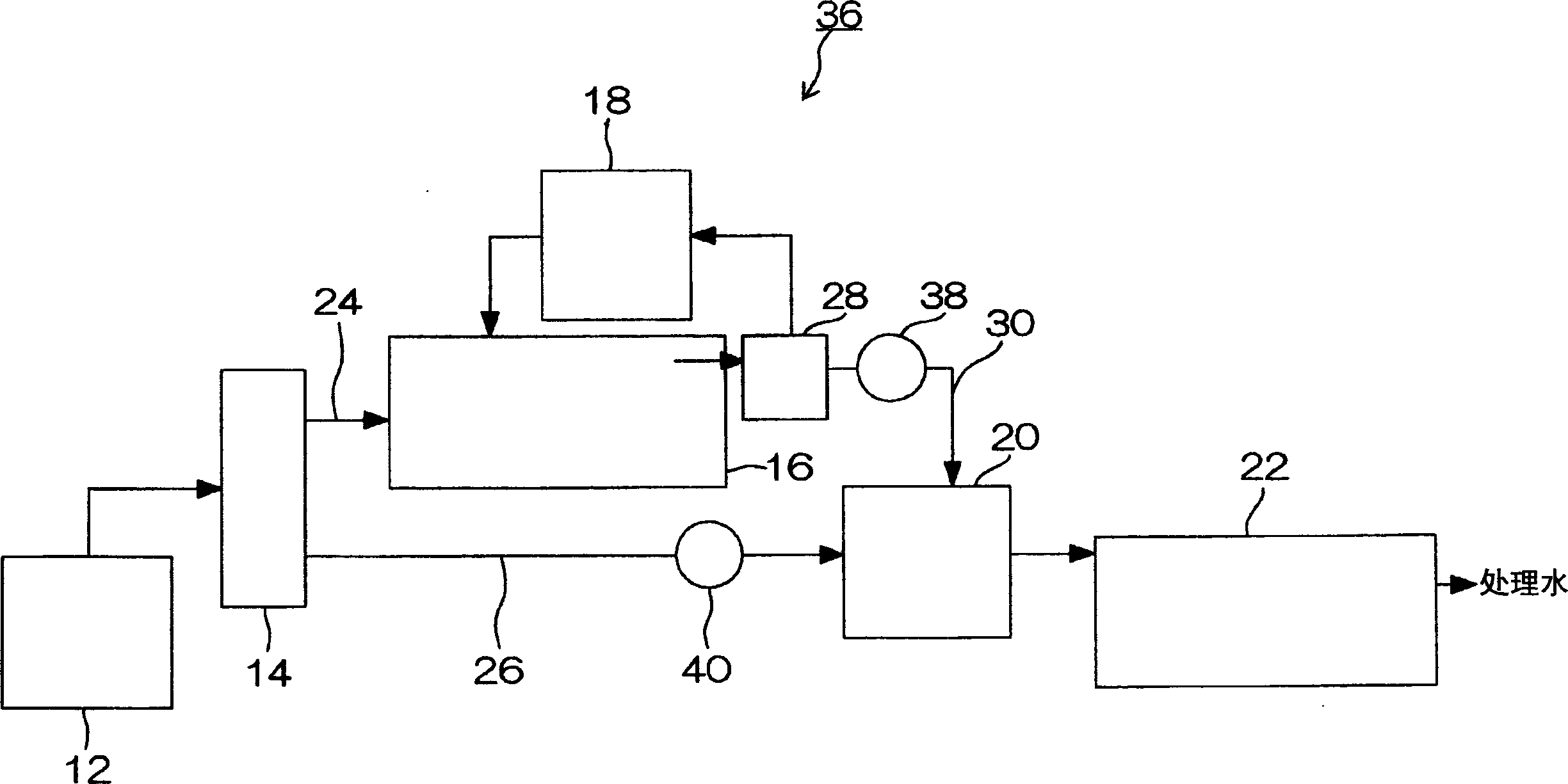

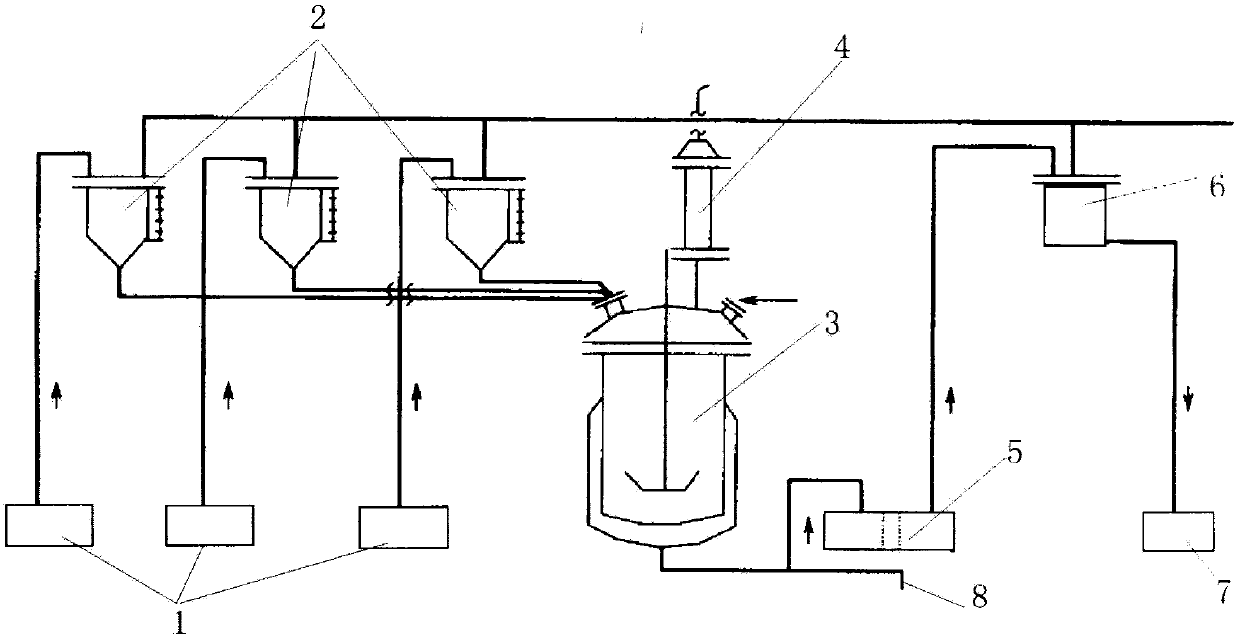

Method and device for removing nitrogen

InactiveCN1532151AAdjust ratioEffective denitrification treatmentImmobilised enzymesTreatment with aerobic and anaerobic processesAmmoniaMixing tank

Provided is a method and an apparatus for removing nitrogen capable of simply obtaining liquid suitable for anaerobic ammonia oxidation and efficiently removing nitrogen component by means of anaerobic ammonia oxidation treatment.Raw water in a raw water tank 12 is distributed to a first delivery line 24 and a second delivery line 26 by a distribution tank 14 and is delivered. The raw water in the second delivery line 26 is directly delivered to a mixing tank 20 and the raw water in the first delivery line 24 is subjected to nitrification treatment in a nitrification tank 16 and, thereafter, is delivered to the mixing tank 20. In the nitrification tank 16, the nitrification treatment is performed by using a carrier which is heat-treated in predetermined heating conditions, and ammonia nitrogen in the raw water is principally converted into nitrite nitrogen. The nitrification treating liquid is mixed with the raw water of the second delivery line in the mixing tank 20 and the mixed liquid is delivered to an anaerobic ammonia oxidation apparatus 22 and is subjected to the anaerobic ammonia oxidation treatment.

Owner:HITACHI LTD

Fish-taste block type composite seasoning

The invention discloses a fish-taste block type composite seasoning and relates to the technical field of composite seasoning production. The fish-taste block type composite seasoning is characterized by consisting of the following raw materials in parts by weight: 0.3-0.8 part of gourmet powder, 0.3-0.8 part of salt, 0.1-0.5 part of sugar, 1-3 parts of dextrin, 10-30 parts of starch, 10-30 parts of pure fish meal, 0.2-1 part of shallot granules, 0.2-1 part of carrot granules, 0.2-1 parts of onion granules and 3-5 parts of plant oil. The fish-taste block type composite seasoning is obtained by fully mixing the raw materials, then performing frying sterilization, pressing the mixtures into blocks and cutting the blocks. The fish-taste block type composite seasoning comprises multiple raw materials, is rich in taste, has the effects of tonifying the spleen, promoting appetite, protecting the health and nourishing, can be directly eaten and is convenient to eat.

Owner:JIESHOU ZHAOLONG FOOD

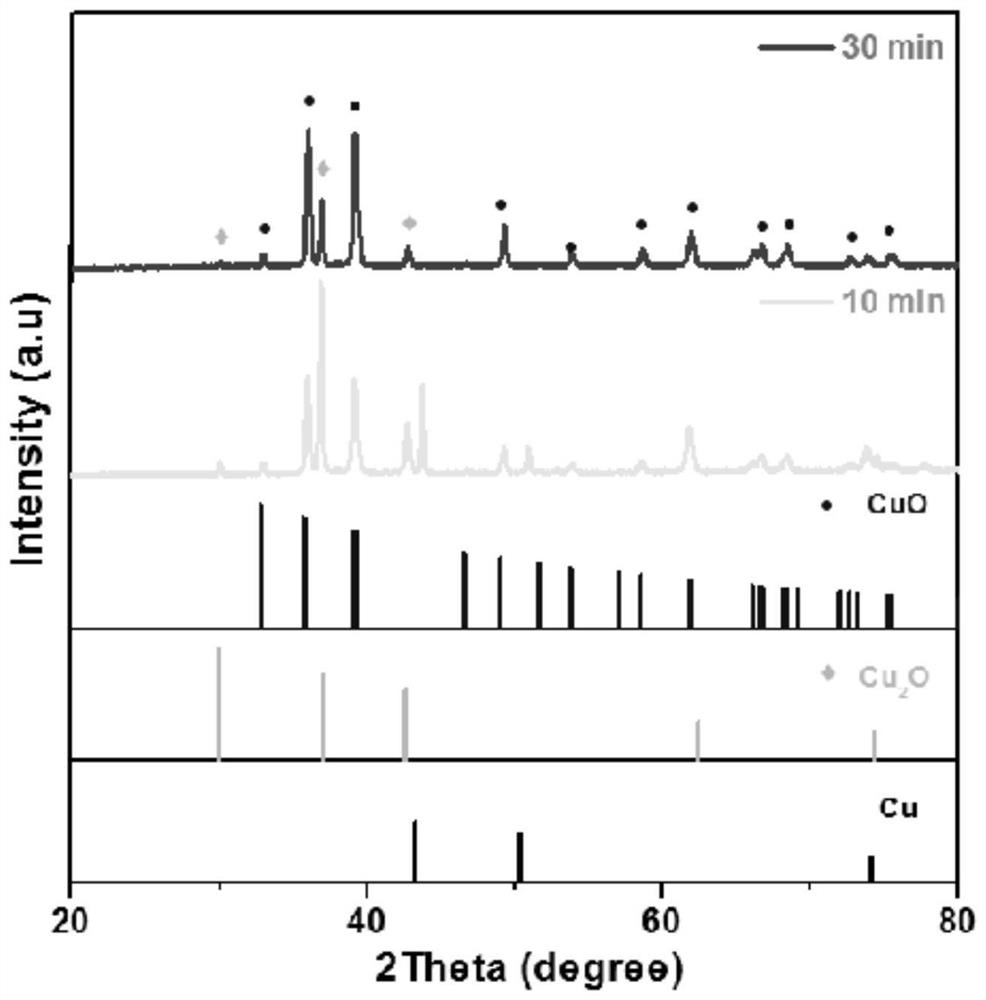

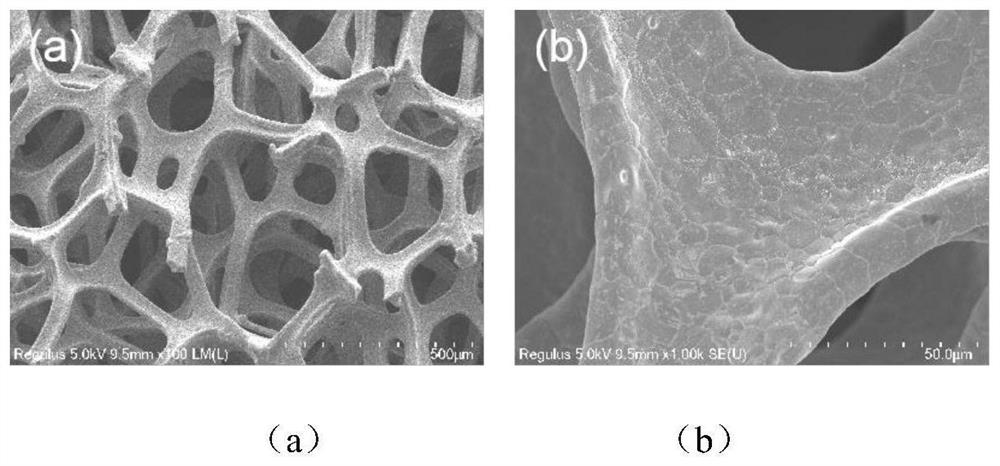

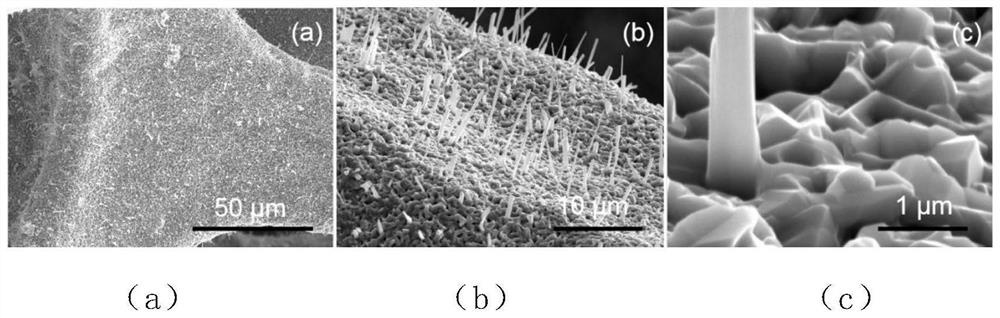

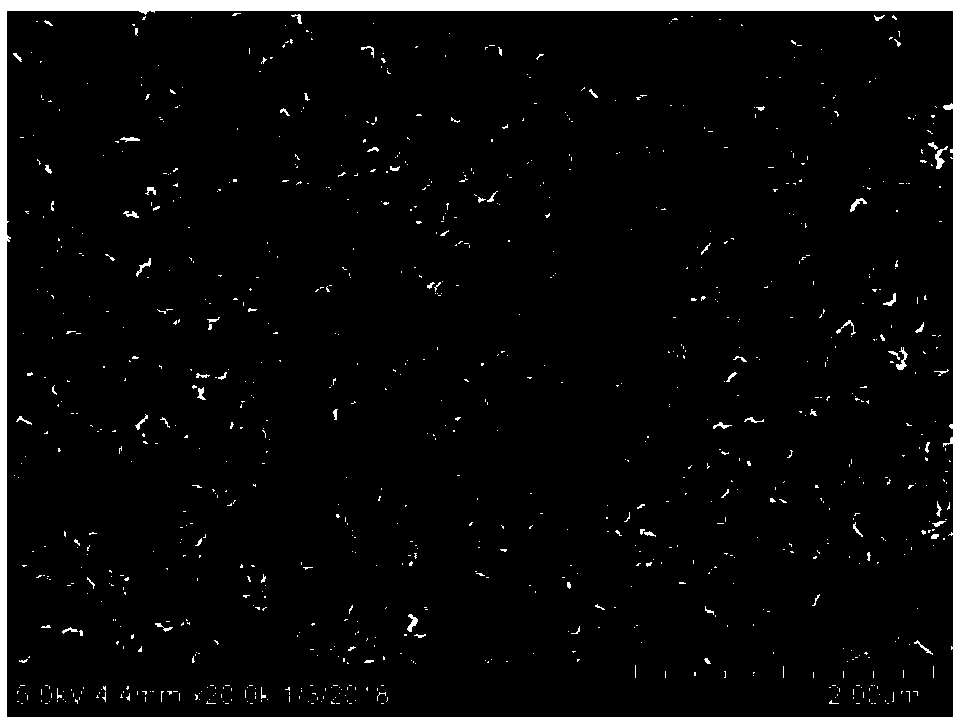

Foamy copper in-situ growth copper oxide/cuprous oxide photocatalytic material as well as preparation method and application thereof

PendingCN113546624ARegulating absorbencyRegulating photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsElectrolytic agentNanoparticle

The invention discloses a foamy copper in-situ growth copper oxide / cuprous oxide photocatalytic material as well as a preparation method and application thereof. The preparation method comprises the following steps of dissolving NaOH in deionized water to obtain a solution A, adding NaCl into the solution A to obtain a solution B, and adding a dispersing agent into the solution B to obtain a solution C, taking a foam copper sheet as an anode, taking an inert electrode as a cathode, taking the solution C as electrolyte, enabling the anode to be subjected to oxidation treatment, then using deionized water for repeatedly washing the foam copper sheet subjected to anodic oxidation, and acquiring a product D attached with a black active substance, and annealing the product D to obtain the foamy copper in-situ growth copper oxide / cuprous oxide photocatalytic material. The phase-controllable copper oxide / cuprous oxide photocatalytic film material is obtained, the microtopography of the material is regulated and controlled from coexistence of nanorods and nanoparticles to regulation and control of the nanoparticles, and the light absorption and photocatalytic activity of the photocatalytic film are regulated and controlled by controlling the phase and the topography.

Owner:SHAANXI UNIV OF SCI & TECH

Vapor-phase epitaxial apparatus and vapor phase epitaxial method

InactiveUS20050166836A1Uniform temperature distributionEasy to adjustAfter-treatment apparatusPolycrystalline material growthHeat flowGas phase

A vapor-phase growth apparatus includes: a reaction furnace which is hermetically closable, a wafer container which is disposed in the reaction furnace, for disposing a wafer at a predetermined position, a gas supply member for supplying a source gas toward the wafer, and a heating member for heating the wafer, wherein the apparatus is designed to form a grown film on a front surface of the wafer by supplying the source gas in a high temperature state while the heating member heats the wafer in the reaction furnace through the wafer container. The wafer container includes: a heat flow control section having a space for disposing a wafer; and a heat flow transmitting section joined to the heat flow control section, for transmitting heat to the wafer disposed in the space; and contact heat resistance Rg between the heat flow control section and the heat flow transmitting section is not less than 1.0×10−6 m2K / W to not more than 5.0×10−3 m2K / W, and the heat flow control section is made of a material having a coefficient of thermal conductivity which is not less than 5 times to not more than 20 times that of the wafer disposed on the heat flow transmitting section.

Owner:JX NIPPON MINING& METALS CORP

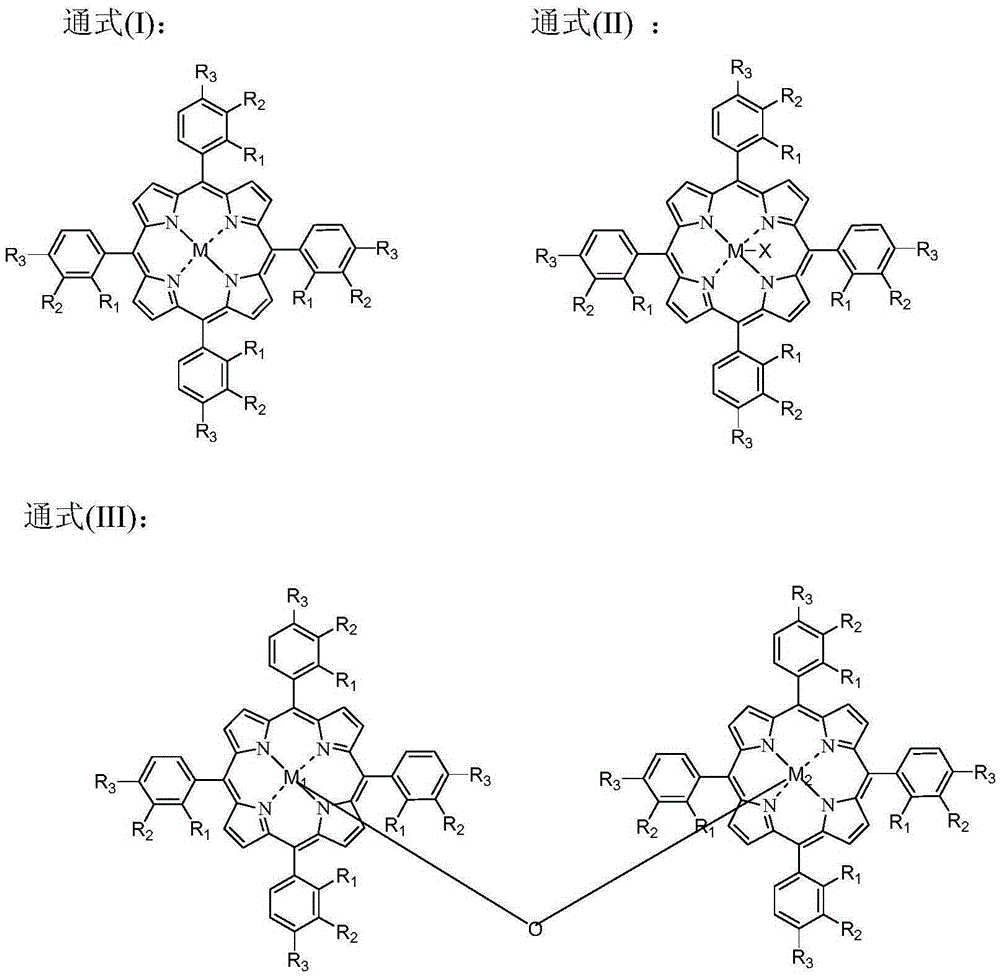

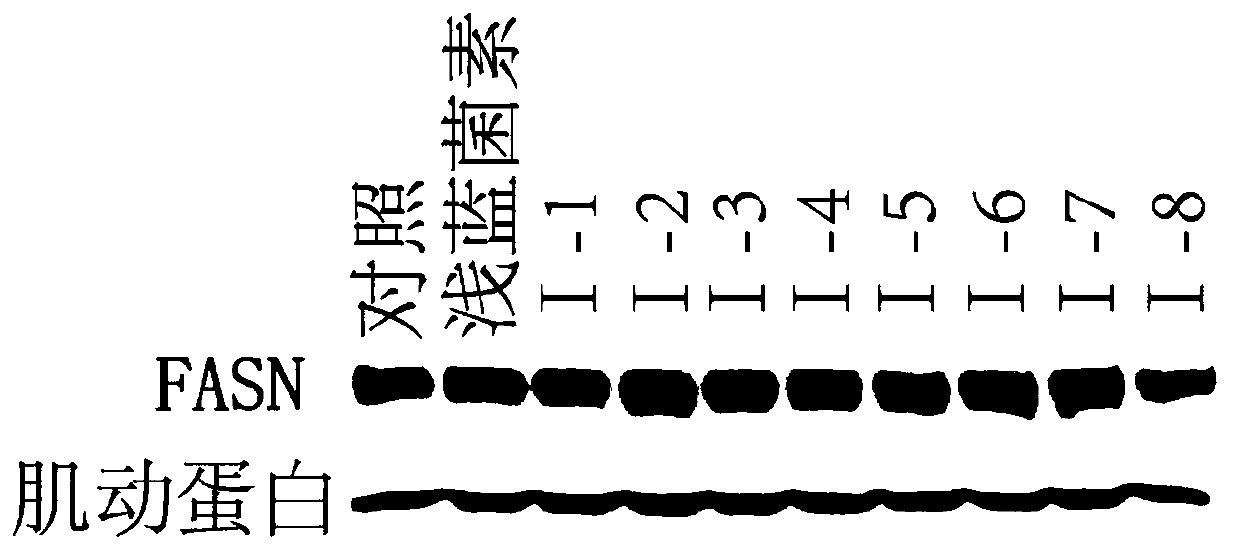

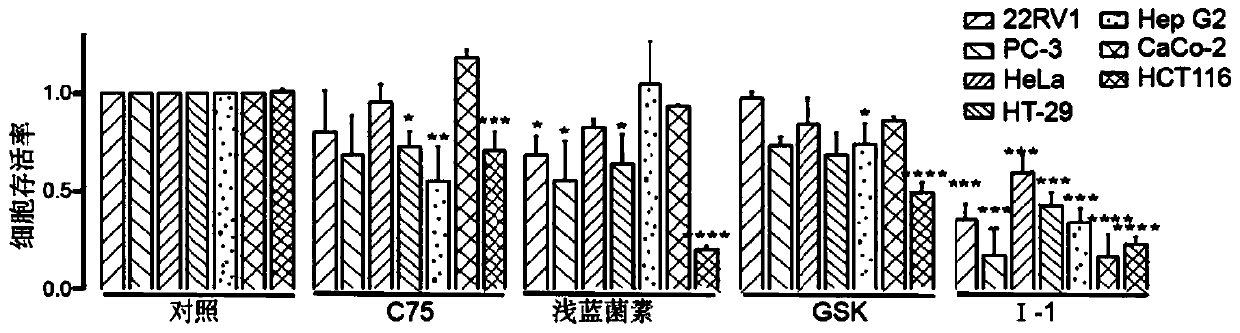

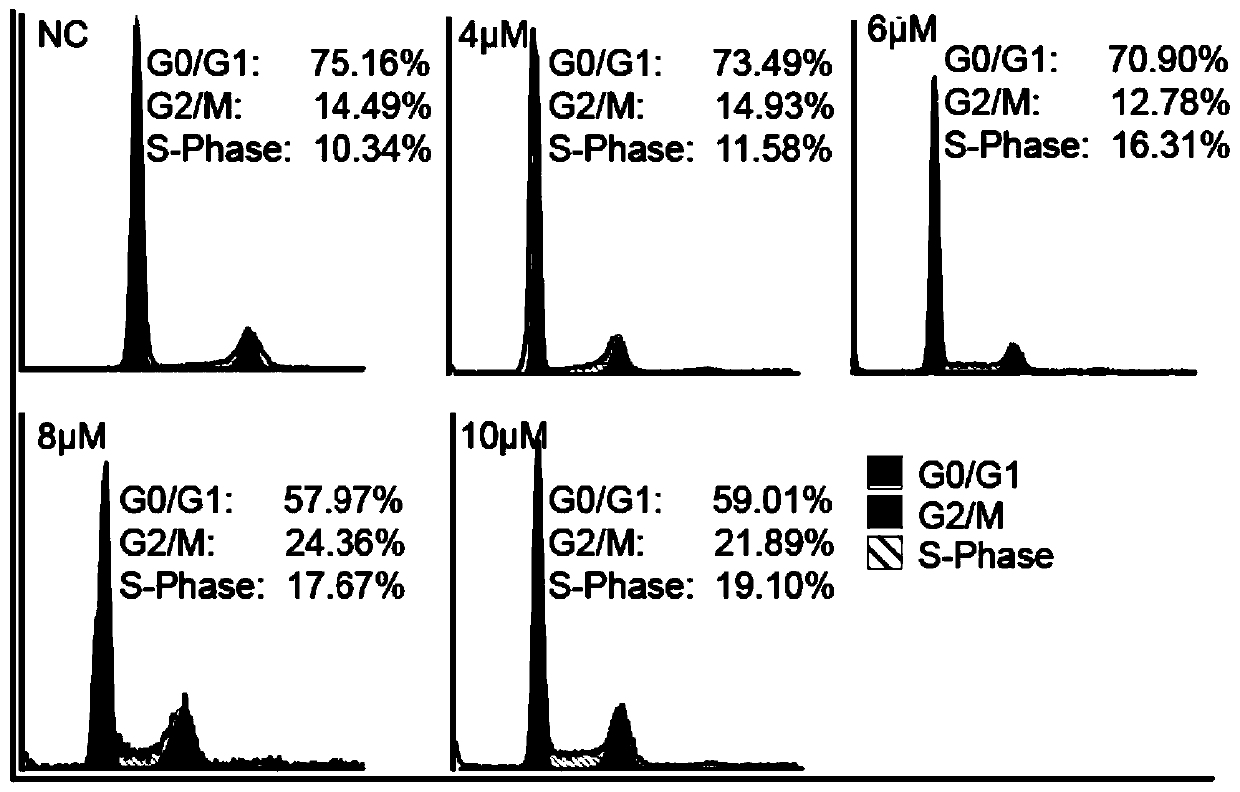

Fat synthetase inhibitor and applications thereof

ActiveCN110354110APrevent proliferationInhibit enzyme activityAntipyreticAnalgesicsDiseaseTherapeutic effect

The invention discloses a fat synthetase inhibitor and applications thereof, and belongs to the technical field of medical biology. The inhibitor can significantly inhibit the activity of fatty acid synthetase without affecting normal expression, and can also adjusting the proportion of fatty acid in cells; the inhibitor has good tumor proliferation inhibition effects, and can make the growth period of tumor cells stagnate in interphase, prevent the tumor cells from splitting, inhibit the proliferation of the tumor cells, promote the apoptosis of the tumor cells and achieve treatment effects on tumor; and the inhibitor can be used for drugs for treating tumor and metabolic related diseases, so that the inhibitor has important clinical application prospects.

Owner:无锡代达康健生物医药科技有限公司

Muskmelon seedling growing substrate

InactiveCN107896918AEnhanced inhibitory effectReduce in quantityGrowth substratesCulture mediaContinuous croppingGreenhouse soil

The invention discloses a muskmelon seedling growing substrate, and belongs to the technical field of seedling growing substrates. The muskmelon seedling growing substrate is prepared from thoroughly-decomposed maize straw, thoroughly-decomposed chicken dung, turfy soil, vermiculite, antagonistic actinomycetes and chitosan, and the mass ratio of thoroughly-decomposed maize straw to thoroughly-decomposed chicken dung to turfy soil, vermiculite to antagonistic actinomycetes to chitosan is 1:(0.08-0.12):(0.8-1.2):(0.8-1.2):(0.04-0.06):(0.06-0.1). According to the muskmelon seedling growing substrate, the substrate contains antagonistic actinomycetes, the antagonistic actinomycetes has the good colonization capability in rhizosphere soil, the good inhibiting effect is achieved for greenhouse soil-borne diseases, and the continuous cropping obstacle can be effectively repaired; the PPO activity of muskmelon seedling stage leaves and roots is improved, and the muskmelon plant disease resistance is improved; the substrate is a compound substrate, the substrate is loose and good in water binding capacity, the total-P, total-K, quick-acting N, quick-acting P and quick-acting K contents arehigh, the fruit quality can be improved, and the fruit yield can be increased.

Owner:新疆生产建设兵团第十师科学技术局

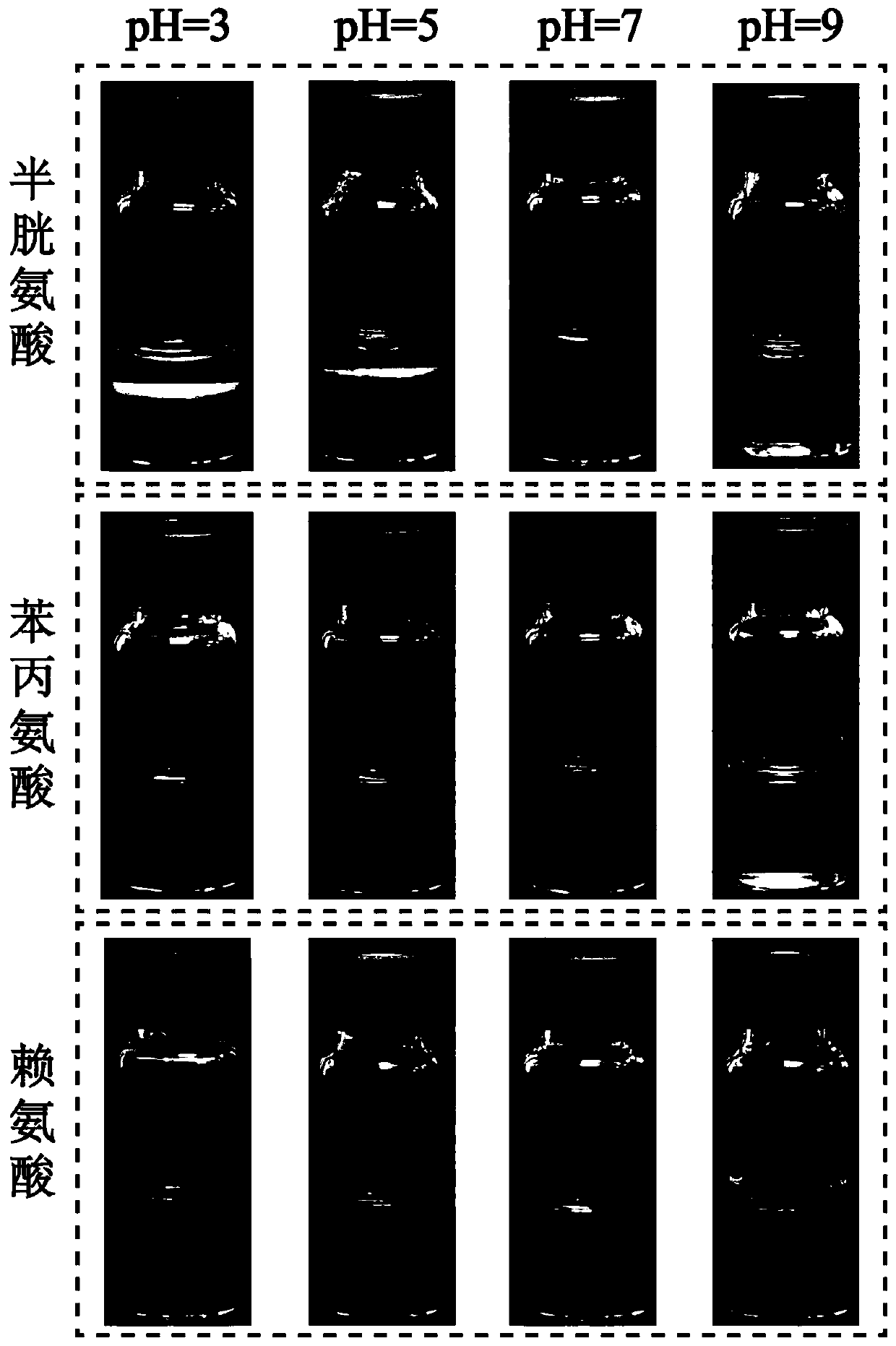

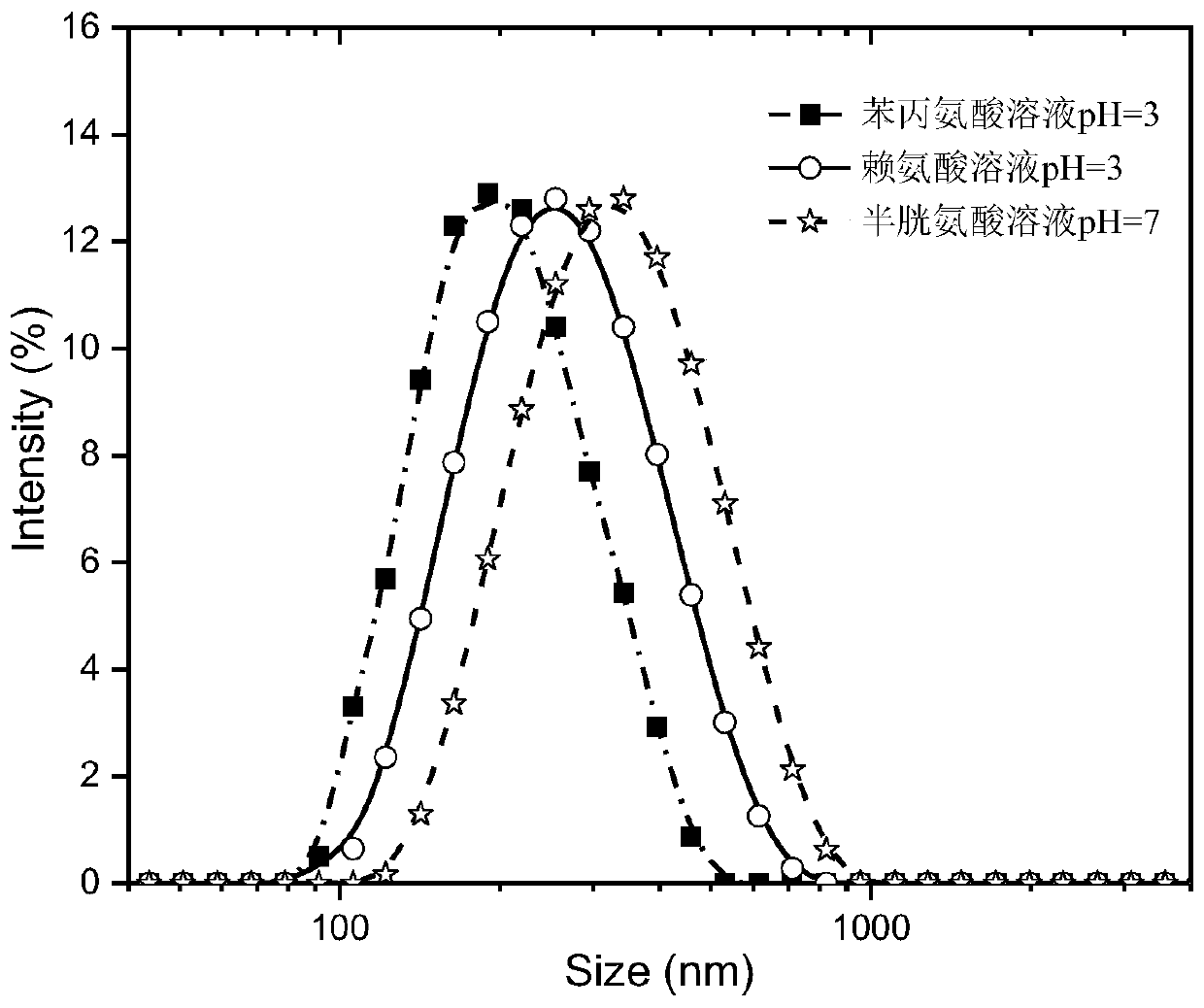

Method for preparing liquid metal nanoparticles from amino acid as ligand

ActiveCN110625125AEfficient preparationEasy to prepareNanotechnologyPh regulationBiocompatibility Testing

The invention discloses a method for preparing liquid metal nanoparticles from amino acid as a ligand. The method comprises the following steps: (1), the amino acid is dissolved in deionized water, and a clarified aqueous amino acid solution is obtained; (2), the pH of the aqueous amino acid solution is regulated to 2-10; (3), liquid metal and zirconium beads are dropwise added to the solution after pH regulation, the mixed solution is subjected to oscillation grinding, and the liquid metal nanoparticles with the particle size of 100-5,000 nm can be prepared. The invention further provides theliquid metal nanoparticles prepared with the method. According to the method for preparing the liquid metal nanoparticles from the amino acid as the ligand, the problems of lower production scale andefficiency, larger particle size and poorer biocompatibility of existing liquid metal nanoparticles are solved.

Owner:SUZHOU UNIV

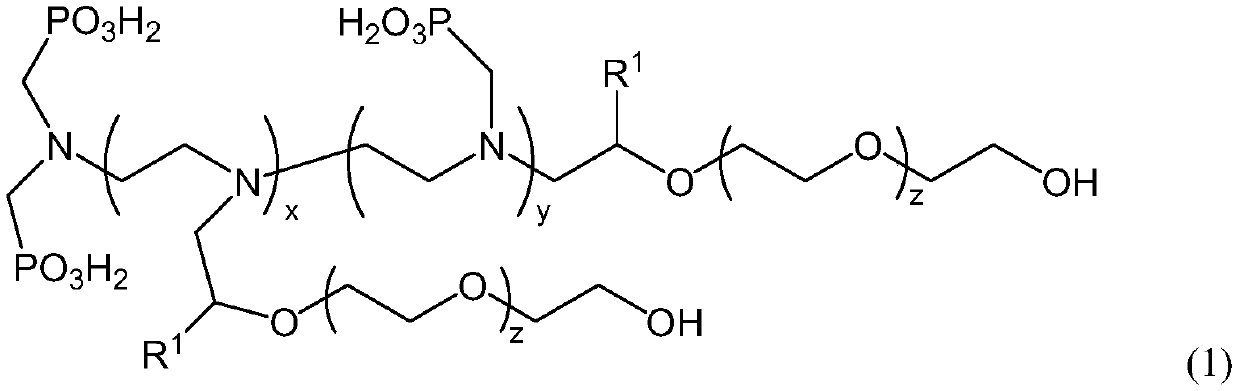

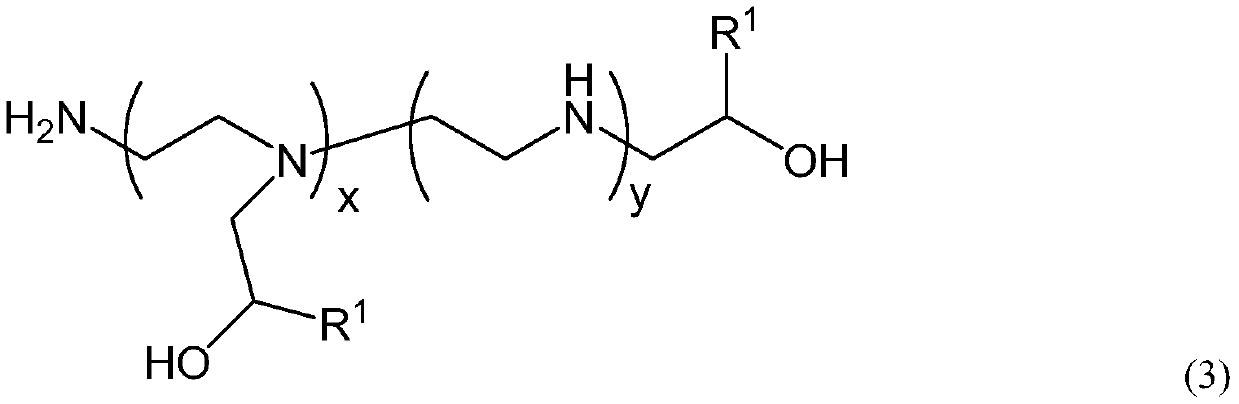

Halogen ion-free phosphate water reducing agent and preparation method and application thereof

The invention discloses a halogen ion-free phosphate water reducing agent and a preparation method and application thereof. The halogen ion-free phosphate water reducing agent comprises a phosphate group-containing multi-branched macromolecule and water, wherein the phosphate group-containing multi-branched macromolecule takes organic amine as a main chain and takes a plurality of grafted phosphorous acid adsorbing groups and polyether side chains as side chains. The halogen ion-free phosphate water reducing agent is convenient to adjust in structure, simple in preparation process and excellent in slump loss resistance and clay tolerance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

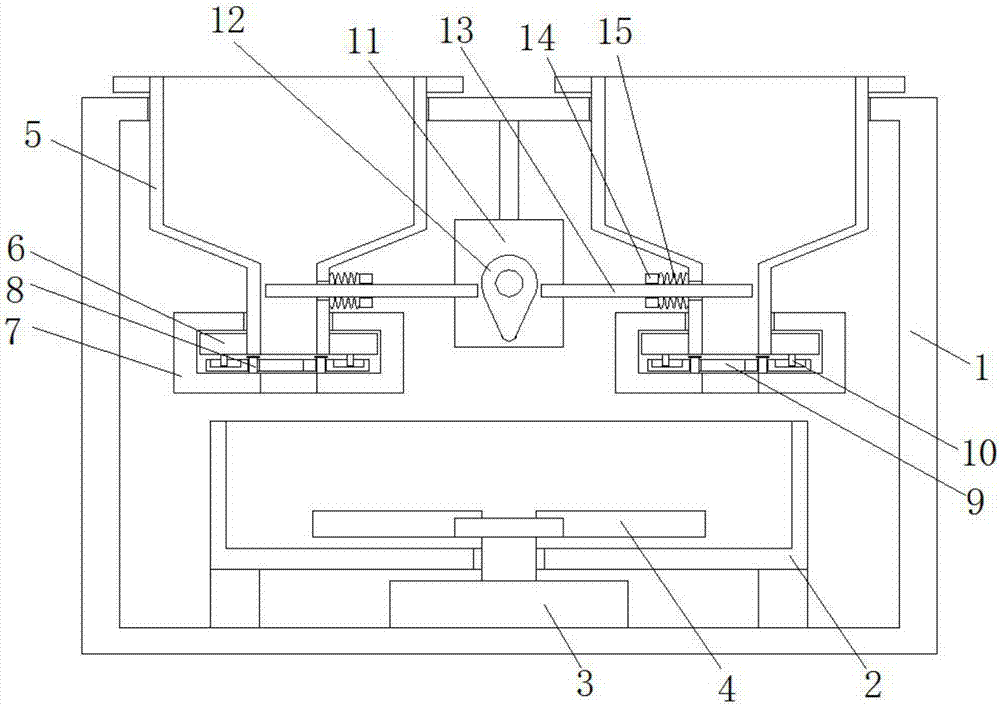

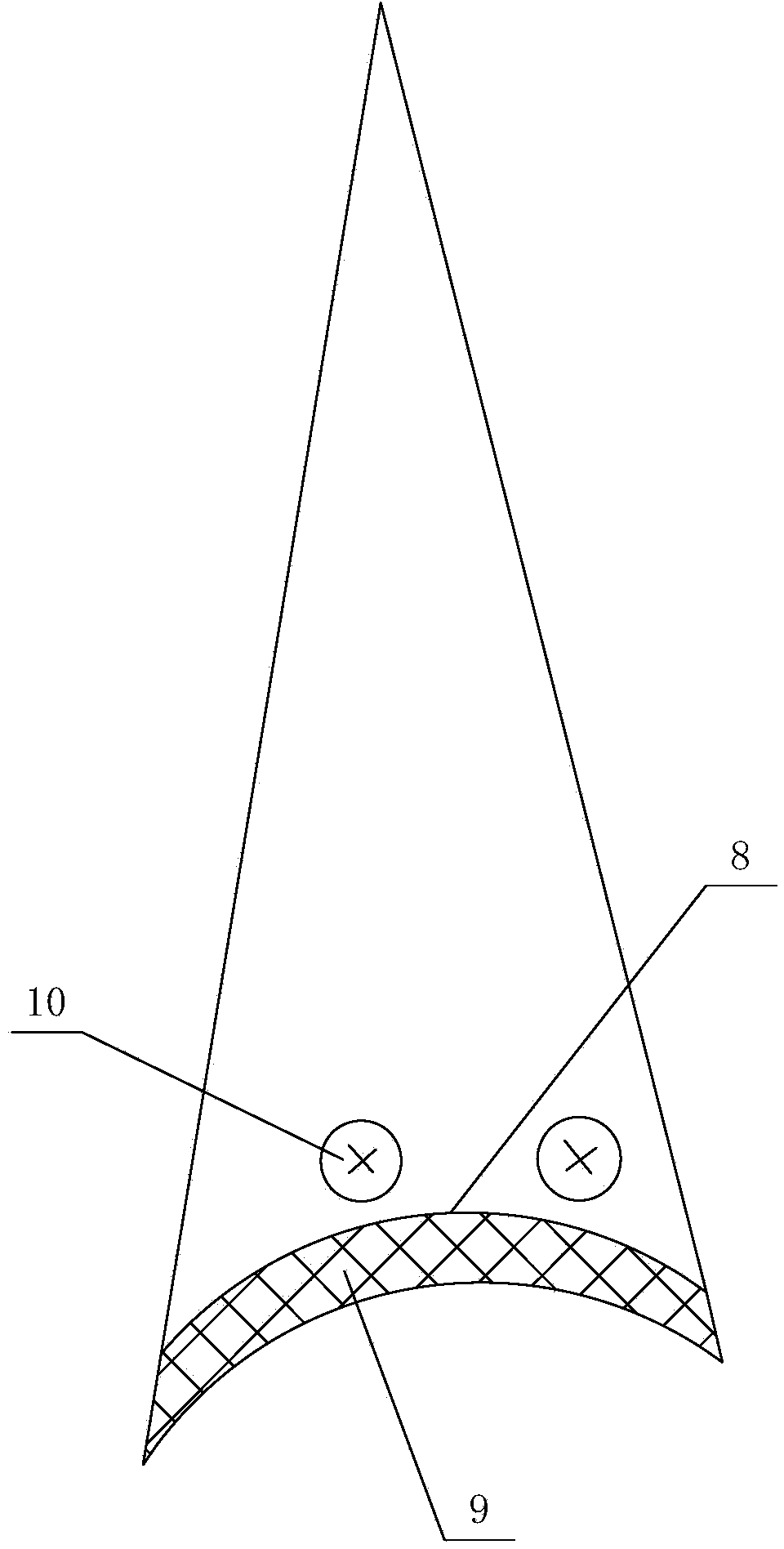

Novel 3D printer nozzle

The invention discloses a novel 3D printer nozzle. The bottom end of a lower adjustment plate (5) is connected with a telescopic limiting mouth; the telescopic limiting mouth comprises an arc-shaped sleeve I (7) with a slideway, and an arc-shaped sleeve II (8) with a slideway; the arc-shaped sleeve I (7) with the slideway is opposite to the arc-shaped sleeve II (8) with the slideway; the left side of the arc-shaped sleeve I (7) with the slideway and the left side of the arc-shaped sleeve II (8) with the slideway are connected with an arc-shaped rod I (9); and the right side of the arc-shaped sleeve I (7) with the slideway and the right side of the arc-shaped sleeve II (8) with the slideway are connected with an arc-shaped rod II (10). The novel 3D printer nozzle is convenient to use, and the preheating time and the nozzle replacing time are shortened.

Owner:芜湖智享三维打印服务有限公司

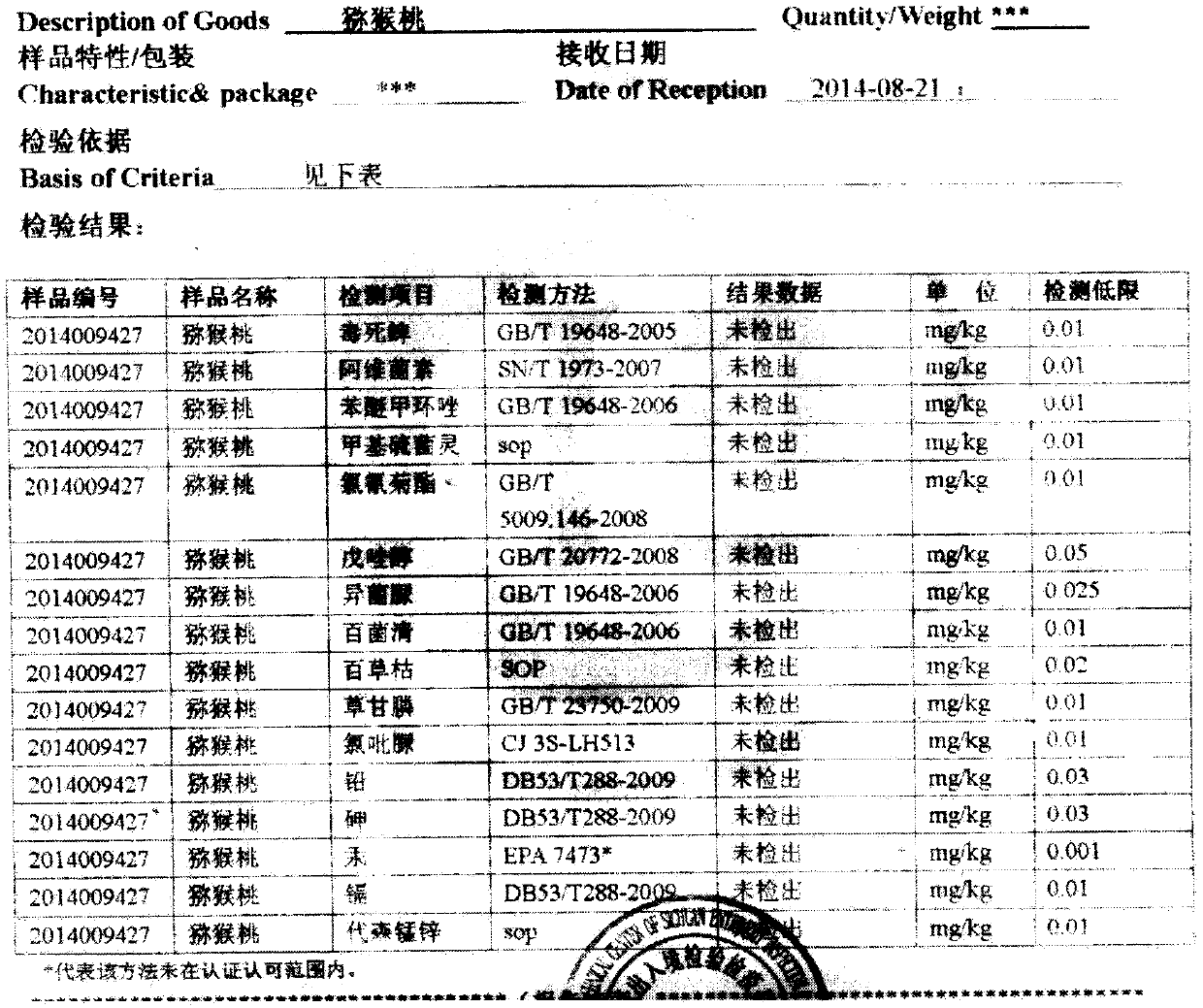

Plant organic converting enzyme degradation agent as well as preparation and use methods thereof

InactiveCN110818480AEfficient removalIncrease organic matterBiocideDead plant preservationPesticide residuePhosphate

The invention discloses a plant organic converting enzyme degradation agent which comprises boric acid, zinc chloride, ammonium sulfate, monopotassium phosphate, potassium nitrate, copper citrate, glucose-6-phosphate dehydrogenase, amino acid, magnesium chloride, manganous nitrate, ferrous sulfate, urea, zinc sulfate and water. The invention also discloses a preparation method and a use method ofthe plant organic converting enzyme degradation agent. The plant organic converting enzyme degradation agent can effectively remove pesticide residues in plants and immobilize heavy metals in plant growth soil at the same time, and can effectively reduce the pesticide residues and the heavy metals in plants, so that the plants reach the detection standards of low pesticide residues and low heavy metals.

Owner:成都碧森生态农业有限公司

Magnesium alloy and macromolecular wire hybrid composite sticking patch and application thereof

ActiveCN108853587AAvoid long-term complicationsStable supportSurgeryTissue regenerationDiseaseAutologous tissue

The invention provides a magnesium alloy and macromolecular wire hybrid composite sticking patch and application thereof. The composite sticking patch is formed through mixed weaving of a magnesium alloy wire material and a degradable macromolecular wire material, and provided with a net structure. The magnesium alloy ad macromolecular wire hybrid composite sticking patch has the advantages that 1, the sticking patch is completely degradable, and absorbed and metabolized by human body in the recovering process from disease, the sticking patch has the good supporting effect in the early implanting stage, and is completely degraded, absorbed and replaced by autologous tissue after tissue recovering is completed in the late stage, and long-term complications caused by a traditional material can be avoided; and 2, by adjusting the size, the appearance and the weaving method of the whole wire material, the composite sticking patches in different types can be obtained, and the sticking patches have different strength and different degradation and absorption time, and can be adaptive to different illness states.

Owner:SHANGHAI JIAO TONG UNIV

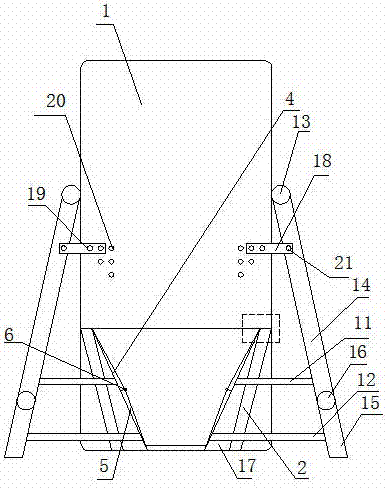

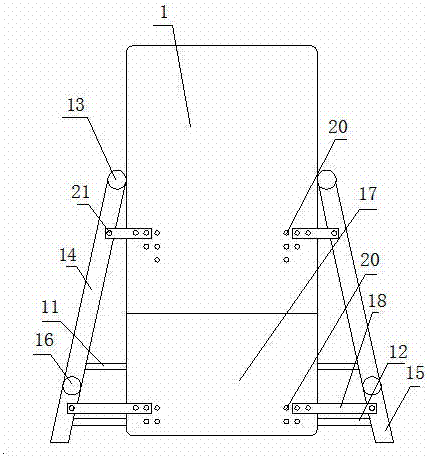

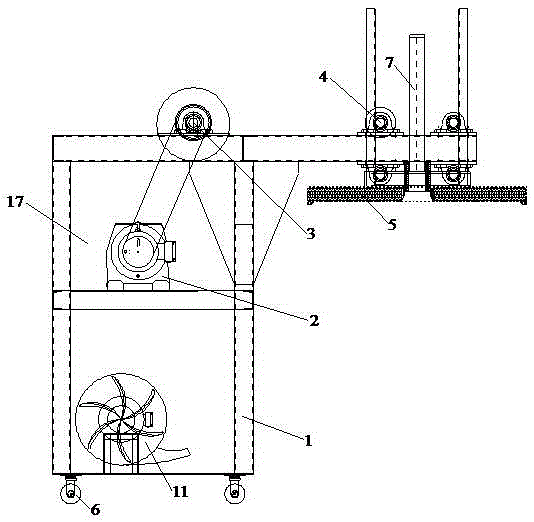

Ladle dryer and control process thereof

The invention discloses a ladle dryer and a control process thereof. The ladle dryer comprises a machine frame; a lifting motor and a transfer shaft driven by the lifting motor are installed at one end of the machine frame; a fixed guide wheel and a burning sealing end cover are installed at the other end of the machine frame; the lifting motor drives the transfer shaft and transmits power to the fixed guide wheel in a chain transmission mode; the burning sealing end cover is driven by the fixed guide wheel to ascend and descend vertically; the burning sealing end cover is provided with a burner; the inlet end of the burner is connected with a hybrid gas pipeline through a connector; the hybrid gas pipeline is connected with a natural gas pipeline and a combustion air pipeline; the outlet end of the burner is provided with a burning sealing end cover. In this way, the ladle dryer and the control process thereof can sufficiently dry casting moulds, adjust the proportion of natural gas to combustion air, ensure the hybrid gas to reach the optimal value and burn sufficiently, and achieve the optimal burning effect.

Owner:JIANGSU HENGLI HYDRAULIC

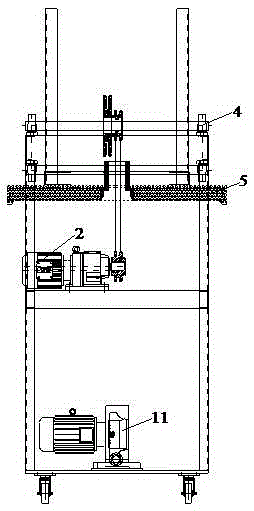

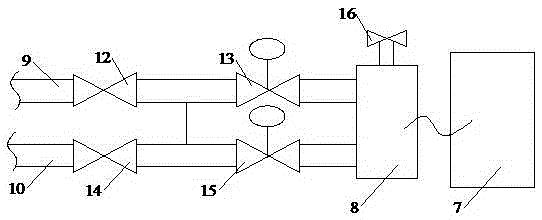

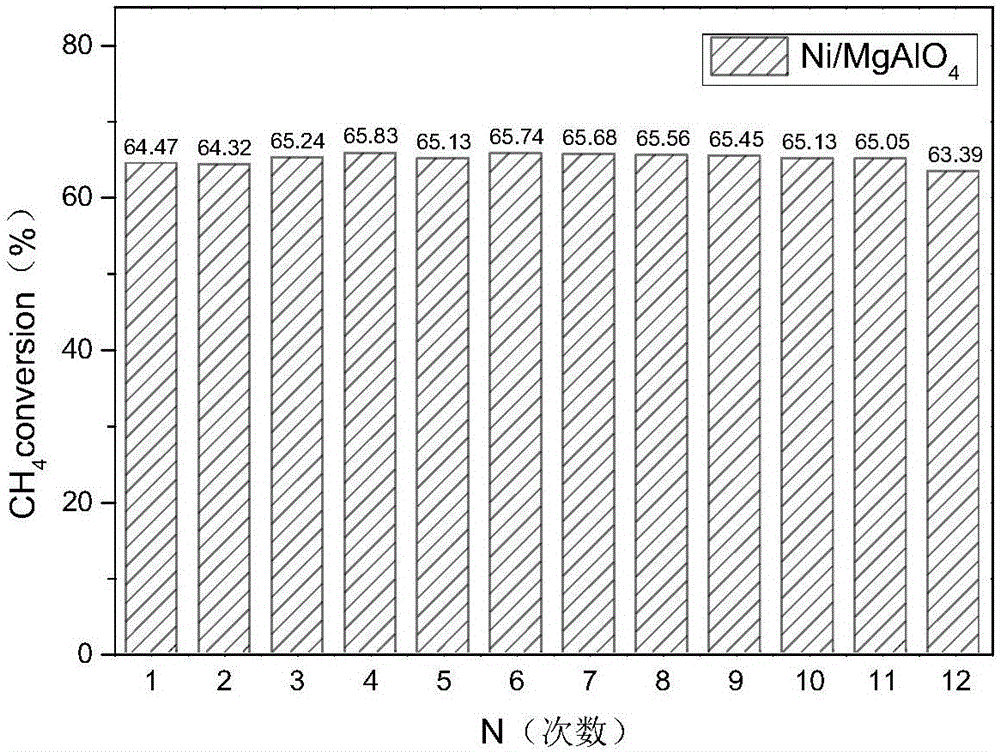

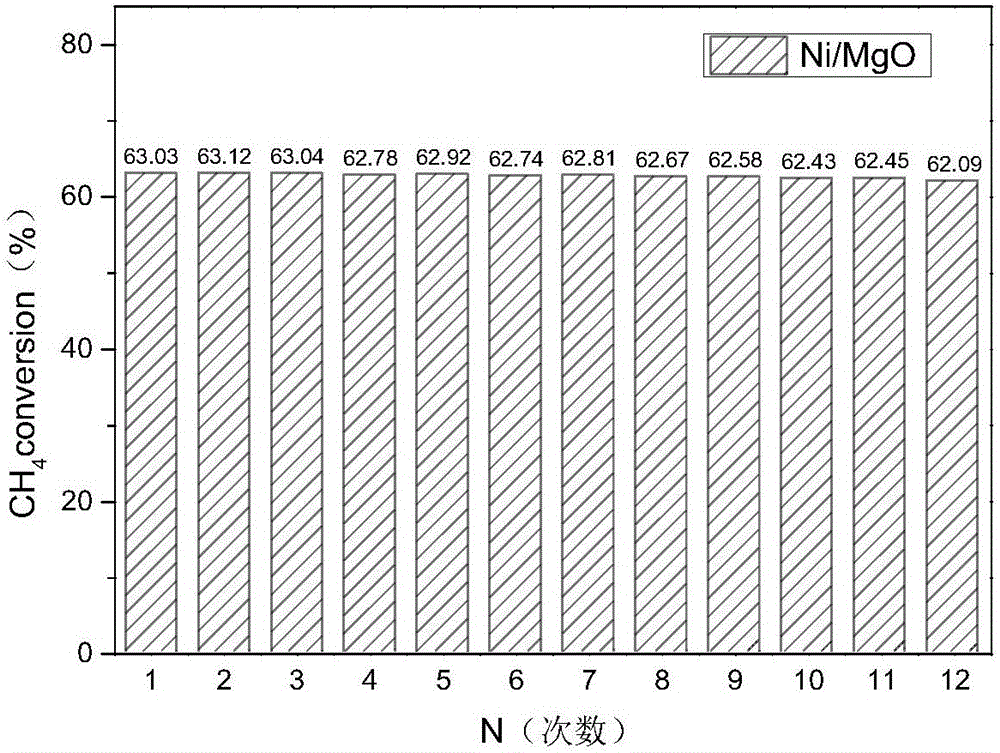

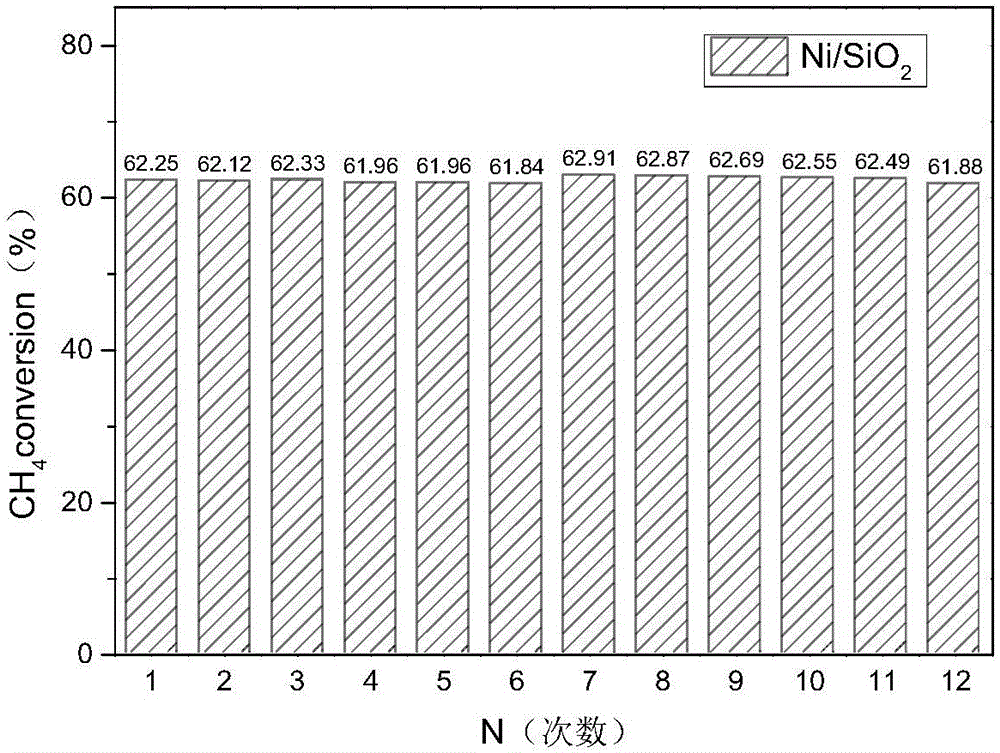

Process for step-by-step improvement of methane conversion through methane cracking and carbon elimination

ActiveCN106082125AReduce energy consumptionRealize anti-carbon depositionHydrogenHydrogen/synthetic gas productionFixed bedCracking reaction

The invention provides a process for step-by-step improvement of methane conversion through methane cracking and carbon elimination. The process comprises the following steps: introducing mixed gas of CH4 and Ar into a fixed bed filled with a catalyst and carrying out a methane cracking reaction at a pressure of 0.1 to 3 MPa and a temperature of 300 to 900 DEG C for 10 to 60 min; carrying out purging with Ar; introducing carbon elimination gas and carrying out a carbon elimination reaction at a pressure of 0.1 to 3 MPa and a temperature of 400 to 900 DEG C for 15 to 60 min; carrying out purging with Ar again to finish a methane conversion reaction once; and repeating the cracking reaction and the carbon elimination reaction to complete the methane conversion reaction a plurality of times. According to the invention, the methane cracking reaction is carried out first and then the carbon elimination reaction is carried out so as to eliminate accumulated carbon the surface of a catalyst; since the separate two-step reactions need low temperature, energy consumption is reduced and sintering of the catalyst at high temperature is avoided at the same time; and the method allows the catalyst to maintain catalytic activity for a long time.

Owner:NORTHWEST UNIV

Water-based tipping paper red ink and preparation method thereof

InactiveCN106433301AStable and mature technology for printing water-based red lettersAdjust ratioInksWater basedAlcohol

The invention relates to water-based tipping paper red ink. The water-based tipping paper red ink is prepared by, by weight percentage, 10-20% of deionized water, 30-45% of alcohol, 0.5-3% of dispersing agent, 0.1-0.5% of defoaming agent, 0.01-3% of thickening agent, 30-40% of connecting material, 5-15% of red powder and 15-30% of black slurry. A preparation method of the water-based tipping paper red ink includes the steps of firstly, preparing materials; secondly, preparing diluent; thirdly, performing primary mixing; fourthly, perform total mixing; fifthly, grinding, filtering and packaging. The water-based tipping paper red ink has the advantages that the defects of water-based tipping water ink in current market are overcome, the printing effect of the red ink is improved by using water-based acrylic resin as the connecting material, using modified acrylic resin and selecting the appropriate wetting and dispersing agent, alcohol-water proportion in the formula is regulated, and the technology for printing water-based red characters on tipping water by using water-based red pigment and special water-based connecting material.

Owner:哈尔滨大东方新材料科技股份有限公司

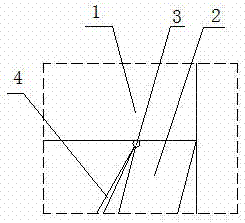

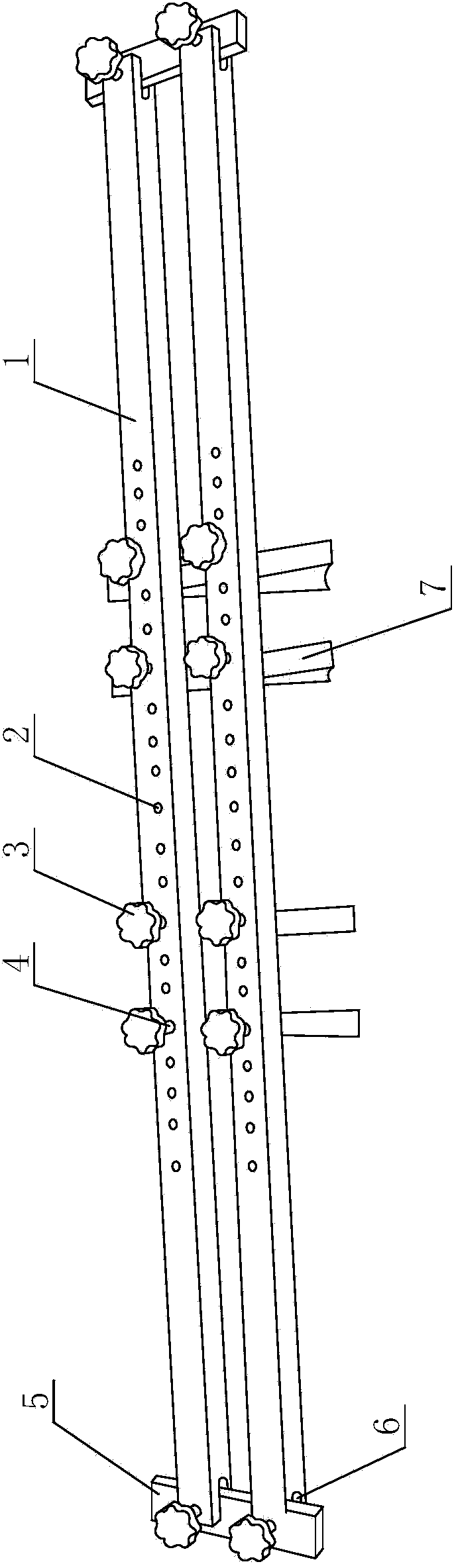

Ink separating device for rainbow printing

The invention discloses an ink separating device for rainbow printing. The ink separating device comprises two fixed rods which are arranged in parallel and distributed obliquely; two ends of the fixed rods are fixed to a support of a side plate of a printing machine; a plurality of threaded mounting holes are formed in the fixed rods, and a separating plate is mounted through screws; the separating plate is composed of a triangular plate with an arc side; an elastic cushion block of an arc-shaped structure is arranged at the arc side of the separating plate; one side of the separating plate is arranged against an inclined plate of the printing plate and while the other side of the separating plate is tightly ejected through the screws on the fixed rods; the arc side of the separating plate is arranged against an ink duct roller. According to the ink separating device for rainbow printing, one side of the separating plate is inclined against the inclined plate of the printing machine and while the other side of the separating plate is tightly ejected with the screws, thus reliable and firm positioning is realized; the separating plates can be simply dismounted by unscrewing the screws, and the operation is convenient and simple; in addition, the plurality of mounting holes are formed in the fixed rods, so that the installation position of the separating plate can be adjusted freely as requirement, and as a result, the ratio adjustment of each type of ink is realized; the ink separating device is simple in structure and easy to be operated.

Owner:WUXI DOUBLE DRAGON INFORMATION PAPER

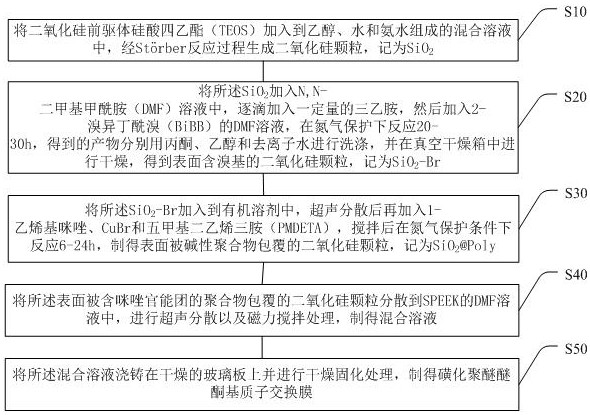

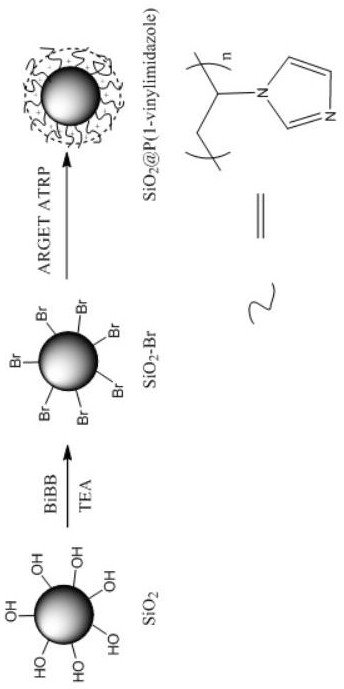

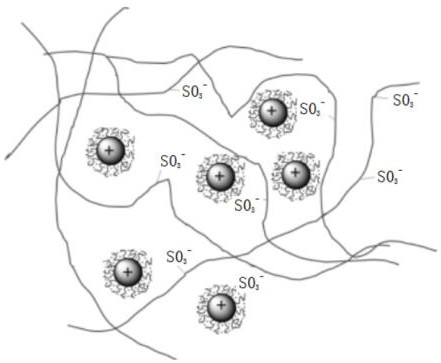

Sulfonated polyetheretherketone proton exchange membrane as well as preparation method and application thereof

ActiveCN114883618AEfficient deliveryImprove water retentionFinal product manufactureFuel cellsSilica particlePolymer science

The invention discloses a sulfonated polyetheretherketone proton exchange membrane and a preparation method and application thereof, and the preparation method comprises the following steps: firstly, preparing silicon dioxide particles by using a Strber method; 2-bromoisobutyryl bromide and Si-OH on the surfaces of the SiO2 particles are subjected to a nucleophilic substitution reaction, and silicon dioxide particles with the tail ends functionalized by bromine functional groups are obtained and marked as SiO2-Br; then initiating 1-vinyl imidazole containing an imidazole group on the surface of the SiO2-Br to generate a polymerization reaction, so as to prepare a silicon dioxide particle of which the surface is coated with a polymer containing an imidazole functional group, and recording the silicon dioxide particle as SiO2 (at) Poly; and finally, adding SiO2-coated Poly into the SPEEK solution, mixing, casting on the surface of glass, and drying and curing to obtain the proton exchange membrane. According to the proton exchange membrane, the membrane stability of the SPEEK membrane under the condition of high sulfonation degree is improved, and the swelling effect of the membrane is reduced.

Owner:佛山市清极能源科技有限公司

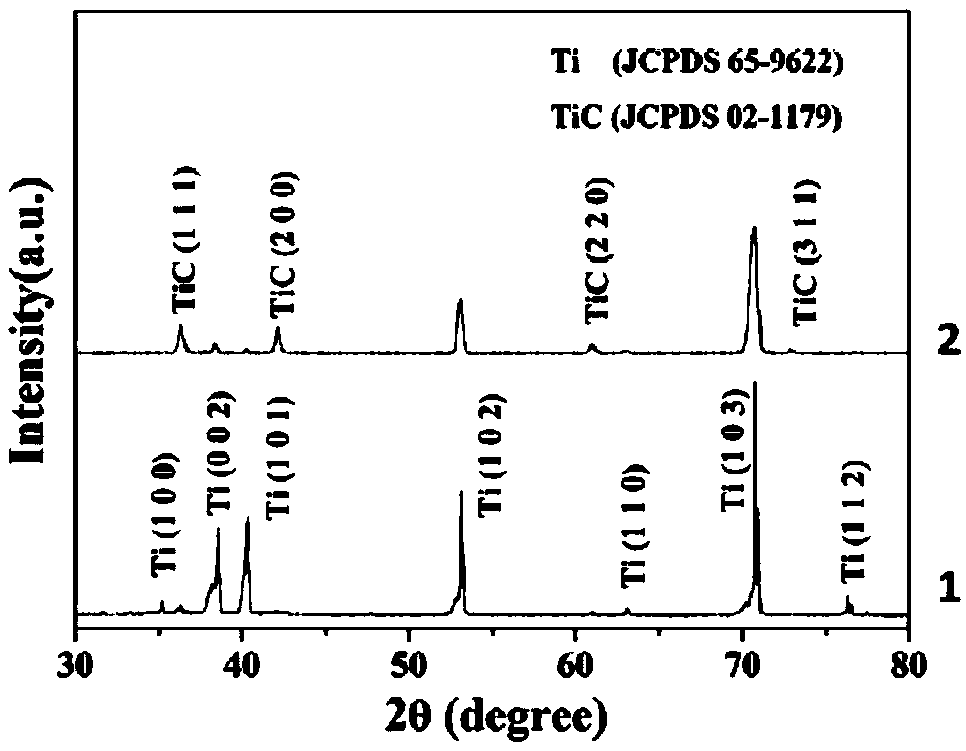

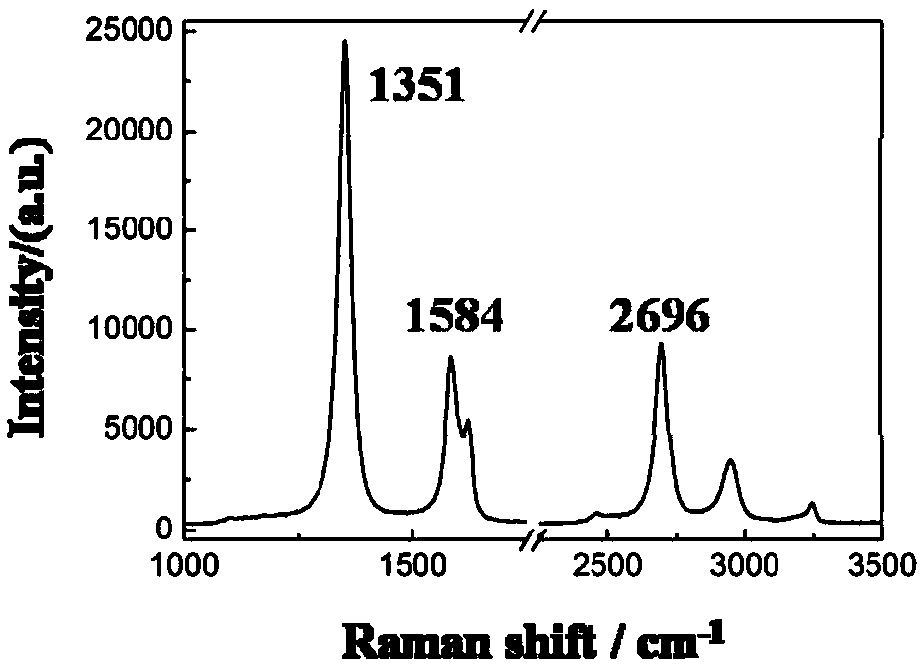

Surface hardness reinforced coating and preparation method thereof

ActiveCN108624863ASimple processReduce pollutionChemical vapor deposition coatingTitanium carbideMethane gas

The invention relates to a surface hardness reinforced coating and a preparation method thereof, and the reinforced coating is composed of a titanium carbide layer and a graphite layer. The preparation method comprises the following steps: (1) ultrasonic cleaning metal titanium or titanium alloy and drying in air by utilizing alcohol and acetone; (2) putting the metal titanium or titanium alloy into plasma reinforced chemical vapor deposition equipment, utilizing a mechanical pump to perform vacuum-pumping until vacuum degree is lower than 1*10<-1>Pa; (3) leading in argon gas of 200 sccm-400 sccm, and heating to 500-900 DEG C at a rate being 3 DEG C / min to 10 DEG C / min; (4) leading in methane gas of 10-50 sccm, closing argon gas, opening a radio frequency source, setting radio frequency power to be 100W-300W, and growing for 0.5-2 hours; and (5) closing the radio frequency source, leading in argon gas of 200 sccm-400 sccm, stopping to lead in methane gas, naturally cooling to the roomtemperature, thereby obtaining the titanium carbide / graphite reinforced coating. The proportion of titanium carbide to the graphite is regulated by controlling parameters such as methane gas flow andgrowth time, so that the performance of the coating is modulated.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com