Novel 3D printer nozzle

A 3D printer and nozzle technology, applied in coating devices, additive processing, etc., can solve problems such as reducing work efficiency, reduce waste, ensure material output, and facilitate use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

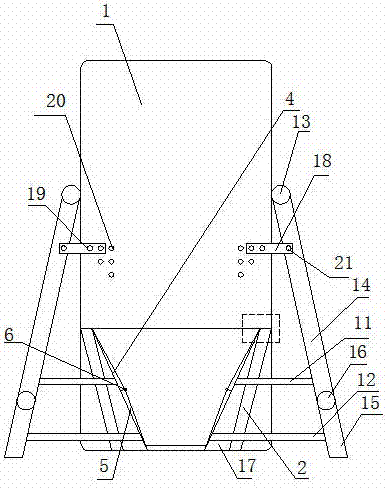

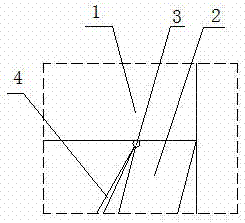

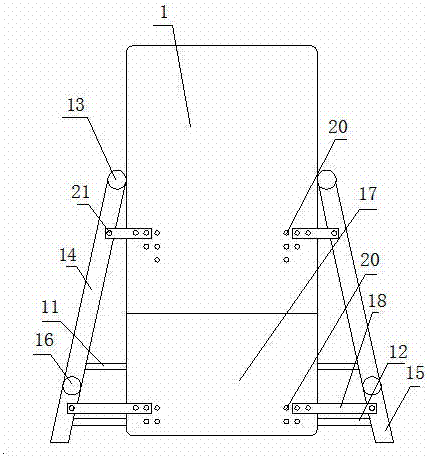

[0020] Such as figure 1 As shown, a new type of 3D printer nozzle, which consists of: extruder body 1, the bottom end of the extruder body 1 is connected to the nozzle 2, and the top of the inner wall of the nozzle 2 is connected by an annular fixed shaft 3. Adjust the guide plate, the adjustable guide plate includes an upper adjustment plate 4 and a lower adjustment plate 5, the upper adjustment plate 4 and the lower adjustment plate 5 are connected by a ring shaft 6; the bottom of the lower adjustment plate 5 The end is connected to the telescopic limit port. The telescopic limit port includes the arc sleeve I7 with slides and the arc sleeve II8 with slides. The arc sleeve I7 with slides and the arc sleeve with slides The arc-shaped sleeve II8 is arranged oppositely, and the left side of the arc-shaped sleeve I7 with the slideway and the arc-shaped sleeve II8 with the slideway is connected with the arc-shaped rod I9, and the arc-shaped sleeve I7 with the slideway is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com