Double-temperature water-heating series two injection type concurrent control valve and manufacturing method thereof

A manufacturing method and technology for controlling valves, applied to valve details, multi-way valves, valve devices, etc., can solve problems such as high cost, achieve cost reduction, high temperature control sensitivity, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

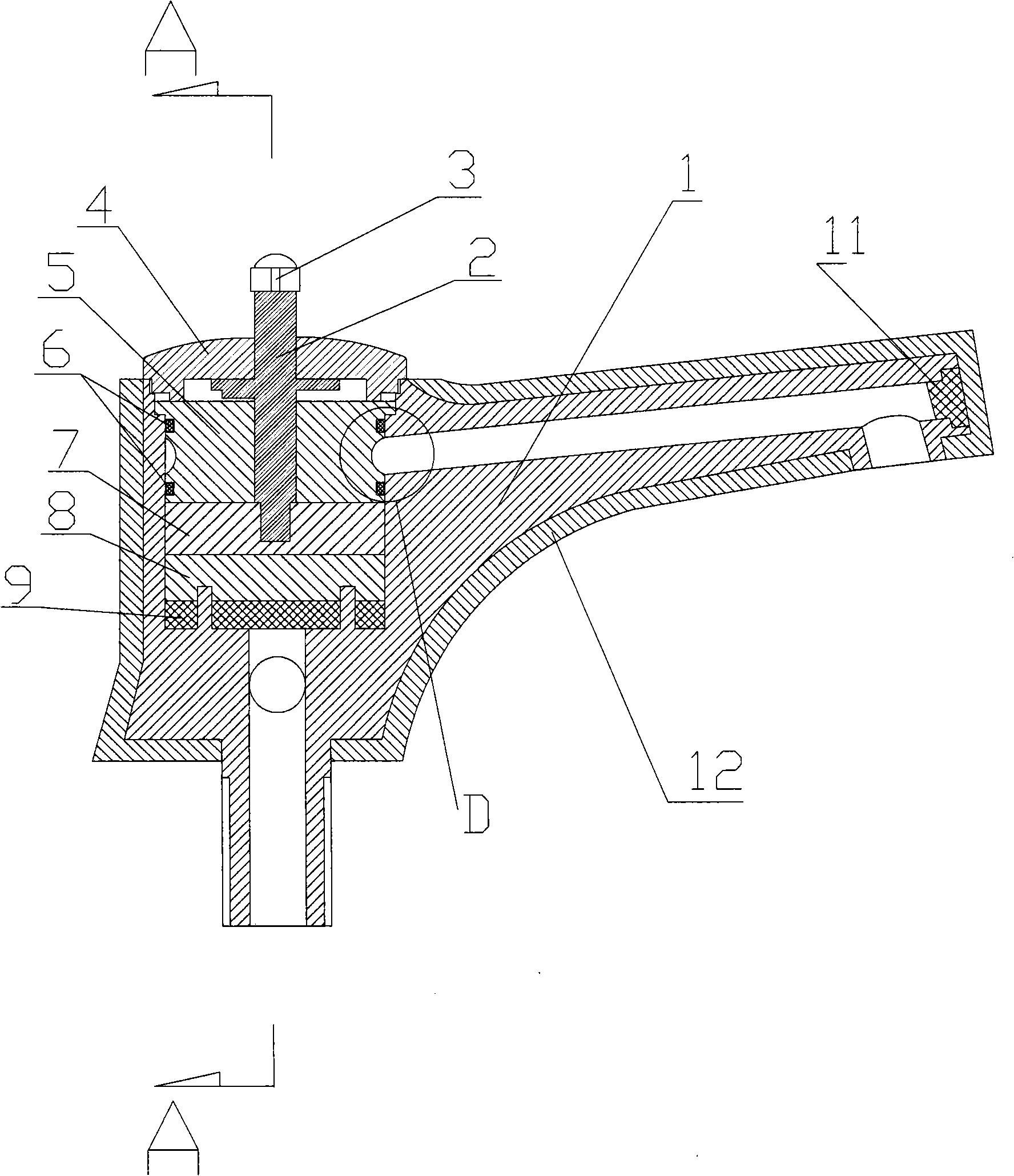

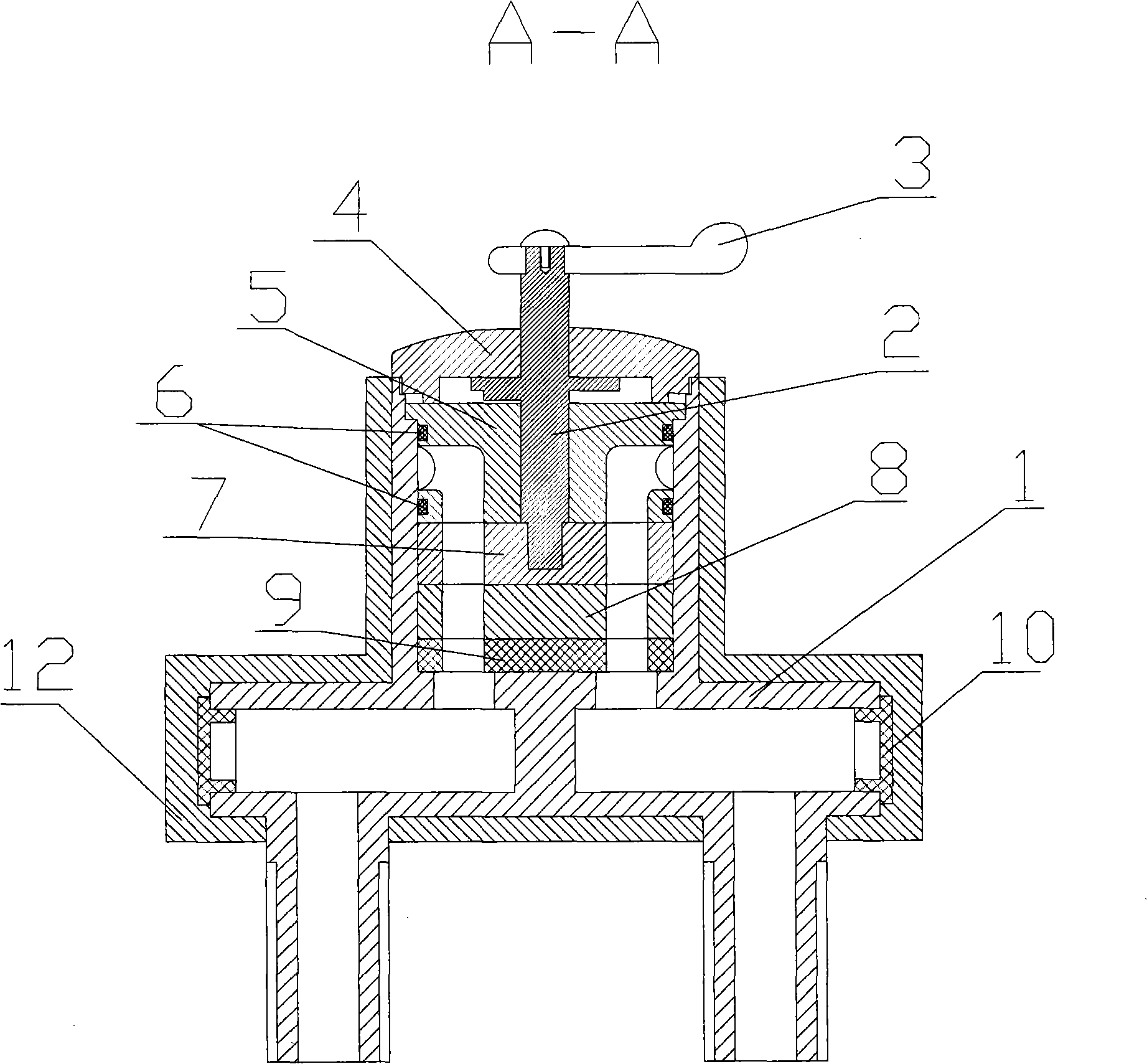

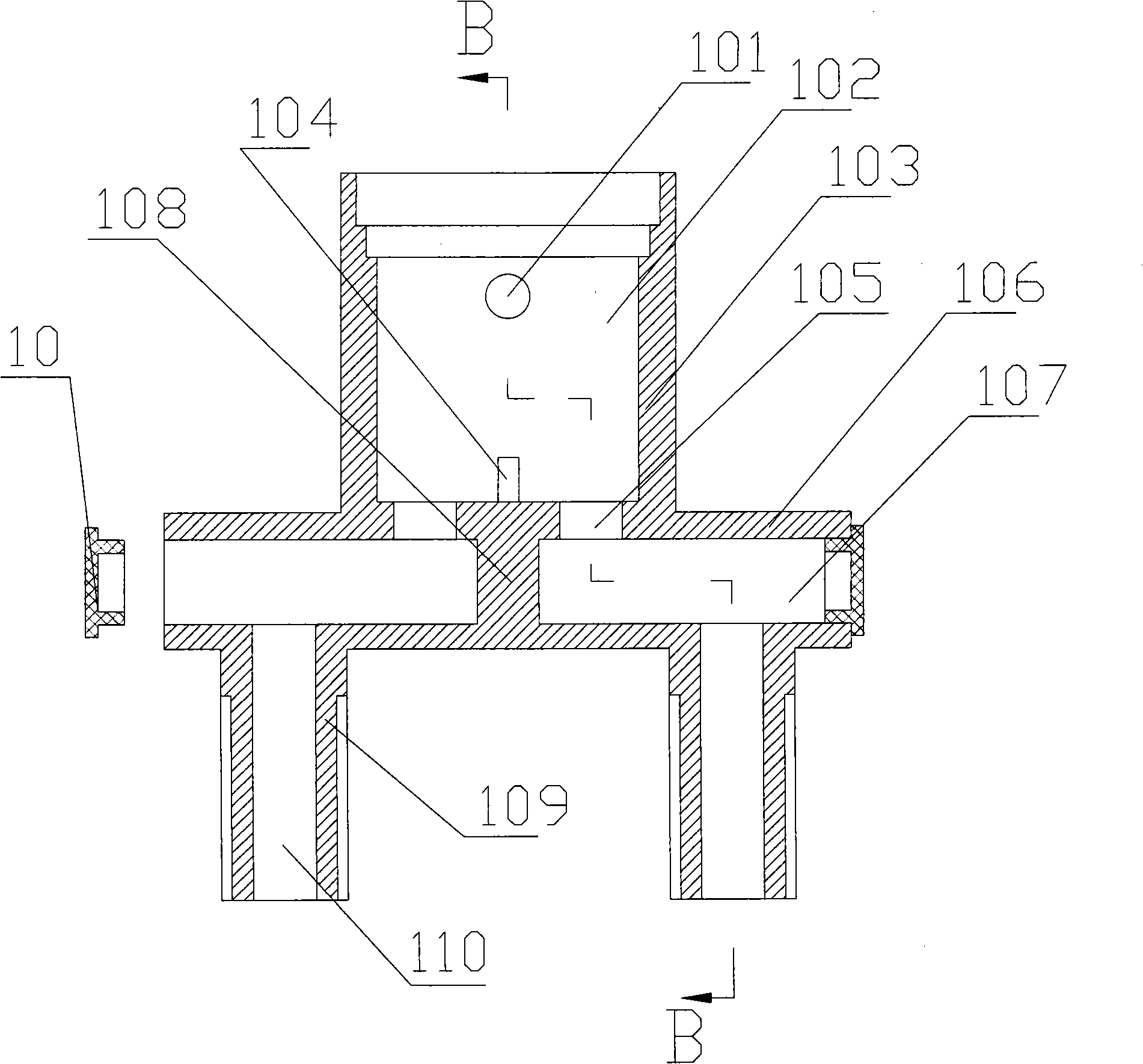

[0058] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 shown.

[0059] 1. Structural composition of double-temperature plumbing series two-injection downstream control valve

[0060] Double-temperature plumbing series two-injection downstream control valve is composed of: one-time molding valve body (1), valve stem (2), rotary handle (3), valve cover (4), valve core upper piece (5), sealing The ring (6), the valve core middle piece (7), the valve core bottom piece (8), the valve core rubber gasket (9), the stuffing cover (10), the stuffing head (11), and the secondary molding valve body (12) are composed.

[0061] The one-step molding valve body (1) of the double-temperature plumbing series two-injection downstream control valve is composed of: a stuffy cover (10), a stuffy head (11), a water outlet pipe of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com