Method for crack communication, channel processing and underground gasification of underground mineral contained organic carbon reservoir

An organic mineral and underground gasification technology, which can be used in fracture communication, carbon-containing organic mineral reservoirs, and new underground gasification technology fields. The effect of capture and resource utilization, suppression of CO2 generation, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

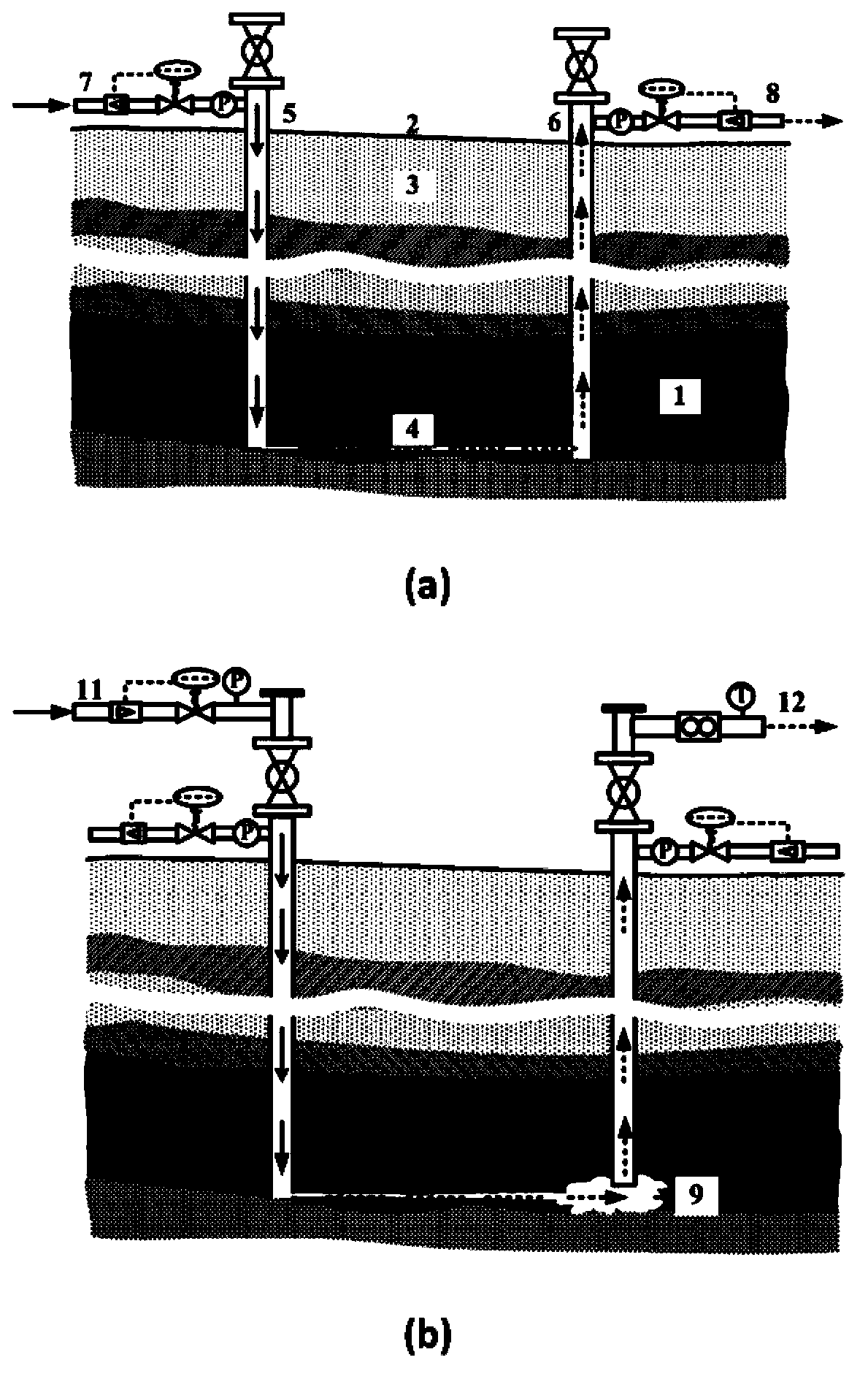

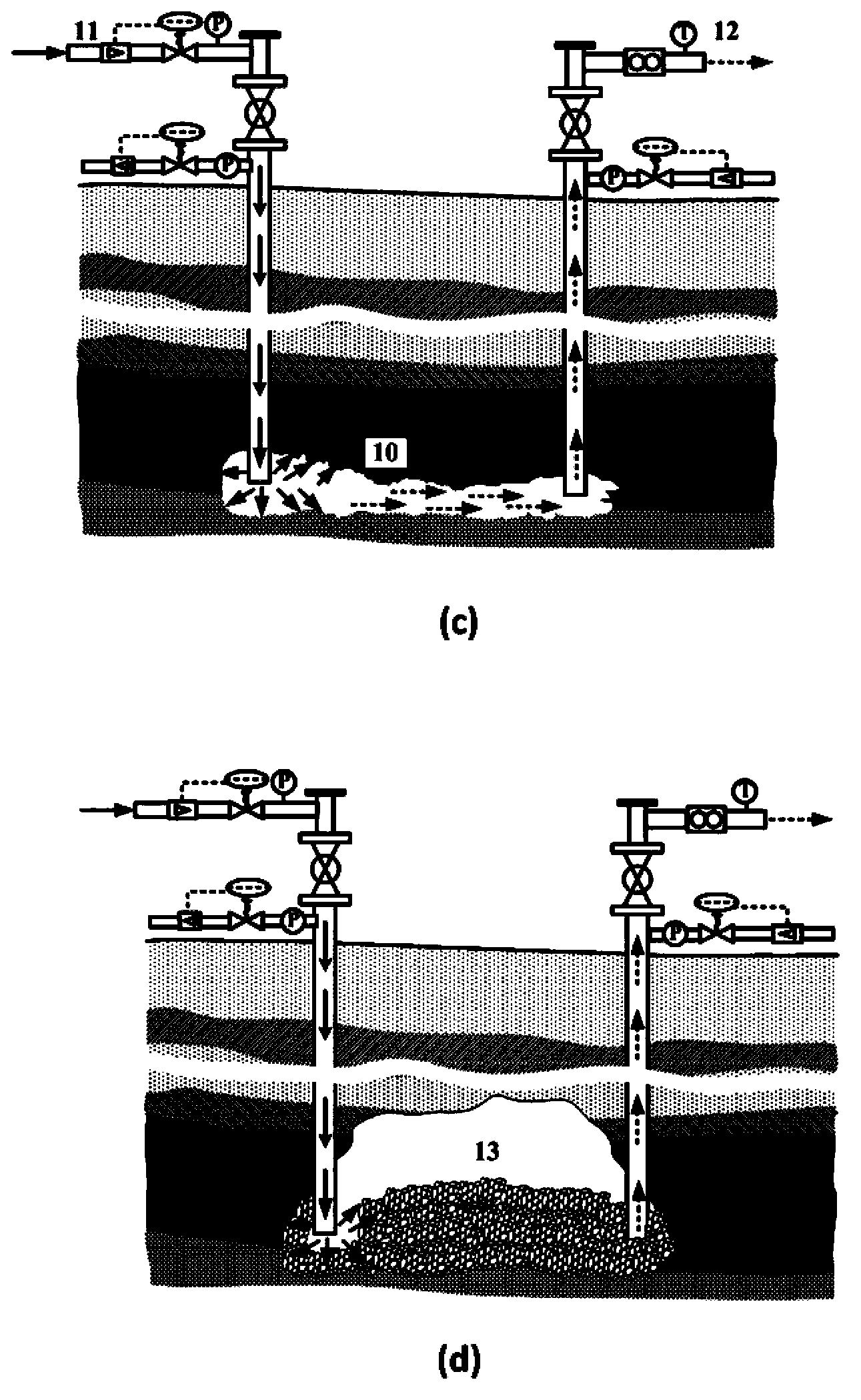

[0091] figure 1 It is a schematic diagram of the process of an underground gasification method according to an embodiment of the present invention, wherein (a) is a fracture communication process; (b) is a channel processing process; (c) is a gasification process; (d) is CO 2 Sealing up, wherein adopting the method of the present invention to carry out gasification mining of the coal seam. In this embodiment, the boreholes are set according to the scope of the proposed gasification coal seam, and the number and layout of the boreholes are determined by the characteristics of the coal seam and the production scale of raw gas, but in order to realize the present invention, at least one air intake borehole and A gas outlet drilling, the specific process is as follows:

[0092] see figure 1 (a). Construct air intake borehole 5 from ground 2 via overburden 3 to coal seam (i.e. carbon-containing organic mineral reservoir) 1, within a certain distance range from air intake borehol...

Embodiment 2

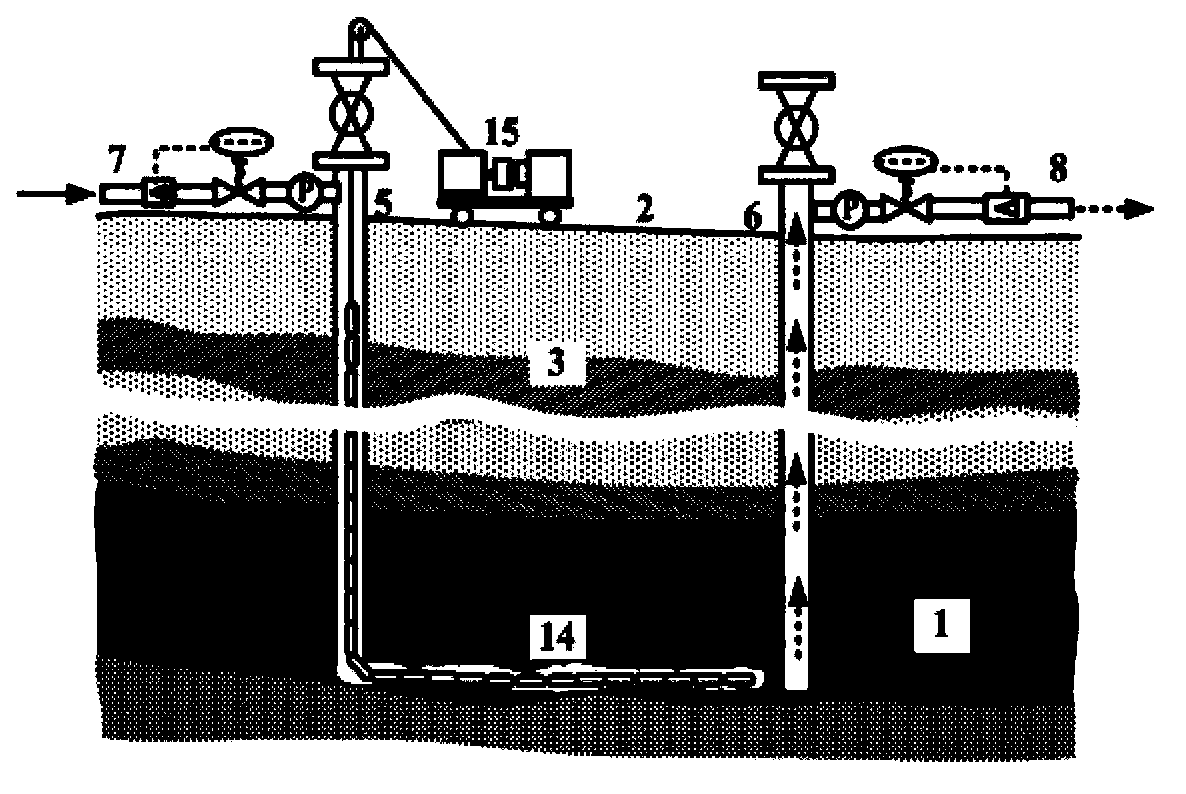

[0102] The method adopted in embodiment 2 is basically the same as that in embodiment 1, except that embodiment 2 adopts ultra-short-radius horizontal drilling technology in the fracture communication step. figure 2 It is a schematic diagram of the fracture communication process of the underground gasification method according to Embodiment 2 of the present invention, wherein ultra-short radius horizontal drilling technology is used to create gaps to form connected fractures. Such as figure 2 As shown, the air intake borehole 5 is constructed from the ground 2 through the overlying rock layer 3 to the coal seam (that is, the carbon-containing organic mineral reservoir) 1, within a certain distance from the air intake borehole 5 (about 40 meters to 100 meters, this Those skilled in the art can construct the gas outlet borehole 6 according to the maximum length that the ultrashort horizontal drill can construct. The air inlet and outlet boreholes 5 and 6 are vertical boreholes...

Embodiment 3

[0106] The method used in embodiment 3 is basically the same as that in embodiment 2, except that in embodiment 3, the carbon-containing organic mineral reservoir already has a fire zone before the fracture communication step, and directional horizontal drilling is used in the fracture communication stage The technology is directly connected to the existing fire zone. image 3 It is a schematic diagram of the fracture communication process of the underground gasification method according to Embodiment 3 of the present invention, wherein the directional horizontal drilling technology is used to directly connect with the fire zone. Such as image 3 As shown, the existing gas outlet borehole 6 has a fire zone 16 at the bottom of the borehole, and it is planned to adopt the method of the present invention to gasify the new coal seam to produce synthetic gas.

[0107] Using the directional drilling method, within a certain distance from the gas outlet drilling hole 6, the air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com