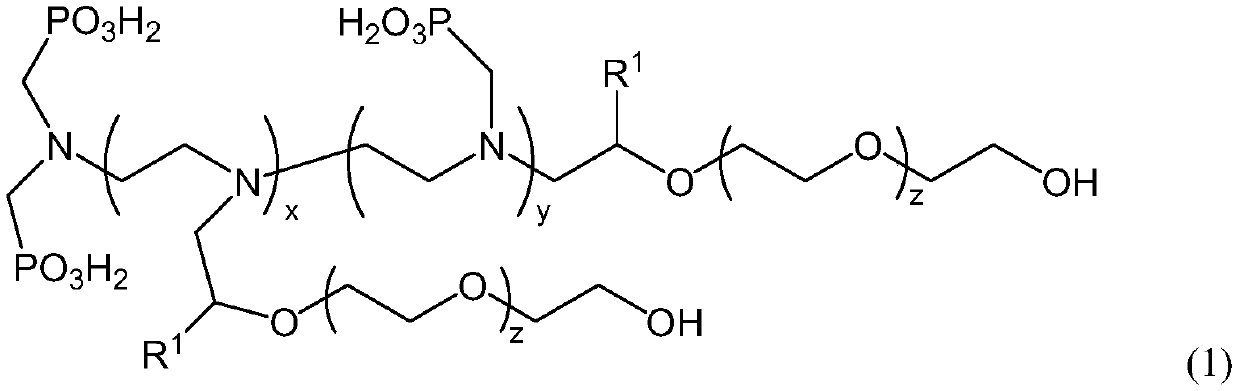

Halogen ion-free phosphate water reducing agent and preparation method and application thereof

A technology of halide ion and water reducing agent, applied in the field of phosphonate water reducing agent and its preparation, can solve the problems of high content of halide ion, many reaction steps, and research, popularization and application affecting the structure-activity relationship of water reducing agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

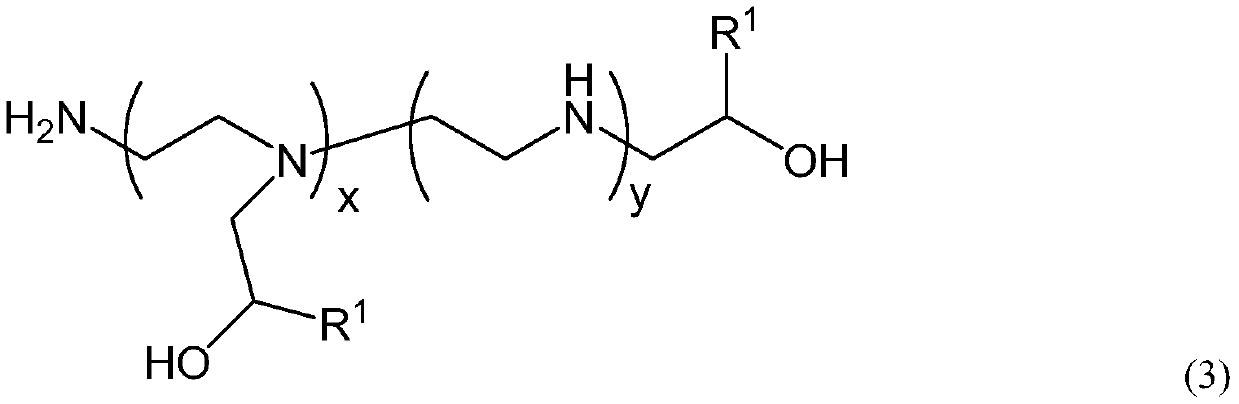

[0058] The synthesis of the amine monomer of embodiment 1 partial ethoxylation

[0059] Preparation of propylene oxide grafted with 1 amino group of ethylenediamine.

[0060] The molar ratio of amino hydrogen to propylene oxide in ethylenediamine is 4:1. Weigh 100.00 parts of ethylenediamine, add 0.50 parts of catalyst sodium hydroxide, seal the polyether reaction kettle, carry out nitrogen replacement 3 times at room temperature, and then pump the negative pressure in the kettle to -0.08~-0.1MPa. When the temperature of the reaction kettle was raised to 100°C, 96.67 parts of propylene oxide was continuously fed in. During the feeding process, the temperature inside the kettle was kept between 100°C and 150°C, and the pressure inside the kettle was between 0.1 and 0.3MPa. After feeding, keep warm and continue to react for 30 minutes, then cool down to about 50°C and discharge to obtain 194.82 parts of tan liquid, denoted as N1.

[0061] Similarly, the following partially eth...

Embodiment 2

[0067] The preparation of embodiment 2 starter intermediates

[0068] N1, dimethyl phosphite is prepared as an initiator intermediate as a raw material.

[0069] The molar ratio of NI, dimethyl phosphite and formaldehyde is 1:3:3. Weigh 100.00 parts of N1 into the reactor, connect the reflux condenser device, open the reactor and the reflux condenser to circulate cooling water. Under stirring conditions, 5 parts of catalyst solid acid catalyst, 279.66 parts of dimethyl phosphite, and 76.27 parts of paraformaldehyde were successively added. After the feeding of materials is completed, the temperature of the reactor is raised to 130° C., and the reaction is kept for 8 hours under the condition of reflux at normal pressure. After the reaction was completed, filter operations were performed sequentially to separate the liquid material from the solid acid catalyst, and the volatile substances in the reaction system were removed by vacuum distillation to obtain 437.12 parts of dar...

Embodiment 3

[0077]The amount of catalyst used is 0.5% of the mass of the starter intermediate. Weigh 100.00 parts of starter intermediate Q1 and 0.50 parts of catalyst magnesium acetate, and add the above materials into the polyether reactor. Nitrogen replacement 3 times, and then vacuum to -0.08 ~ -0.1MPa. Raise the temperature of the reactor to 100°C, and start feeding 1552.89 parts of ethylene oxide continuously. During the feeding process, keep the temperature in the reactor between 120-130°C and the pressure in the reactor between 0.2-0.5 MPa. After feeding, keep warm and continue to react for 30 minutes, then cool down to about 80°C and discharge. To obtain 1647.91 parts of light brown yellow liquid with a certain viscosity, add 1098.61 parts of water for dilution.

[0078] Add 77 parts of 32% sodium hydroxide aqueous solution to the polyether intermediate aqueous solution, raise the temperature to 80°C, and react for 5 hours to obtain a light brown yellow transparent solution. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com