Sulfonated polyetheretherketone proton exchange membrane as well as preparation method and application thereof

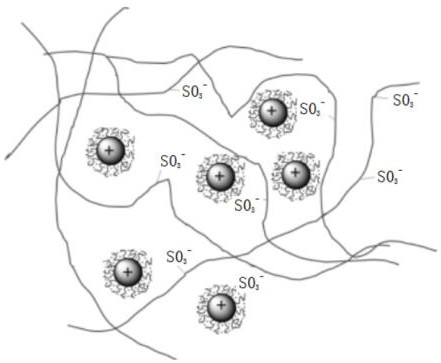

A sulfonated polyether ether ketone and proton exchange membrane technology, applied in the field of proton exchange membrane, can solve the problems of excessive swelling, poor mechanical properties and structural stability, and high water absorption, so as to reduce swelling, improve mechanical properties, and improve water retention. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

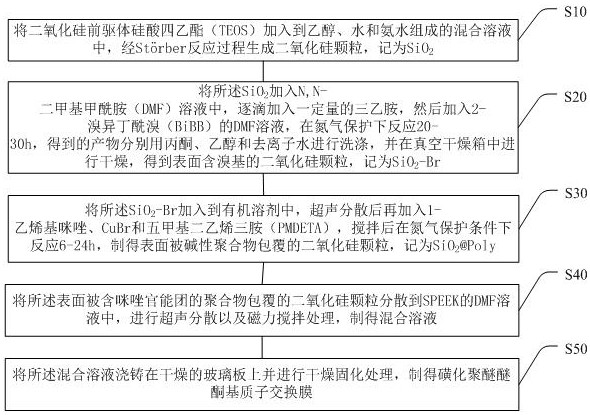

[0045] A preparation method of a proton exchange membrane, comprising the following steps:

[0046] 1) Sulfonation of polyether ether ketone

[0047] 20 g of PEEK was dried in an oven at 105 °C overnight, and then dissolved in 200 mL of concentrated sulfuric acid at room temperature. After dissolving, the temperature was raised to 45°C, and the reaction was carried out under vigorous stirring for 36 hours. After the reaction, the reacted solution was poured into ice water, and the resulting precipitate was washed with deionized water to remove excess acid until the pH of the polymer was 7; the final product (SPEEK) was placed in an oven at 105°C Dry to constant weight.

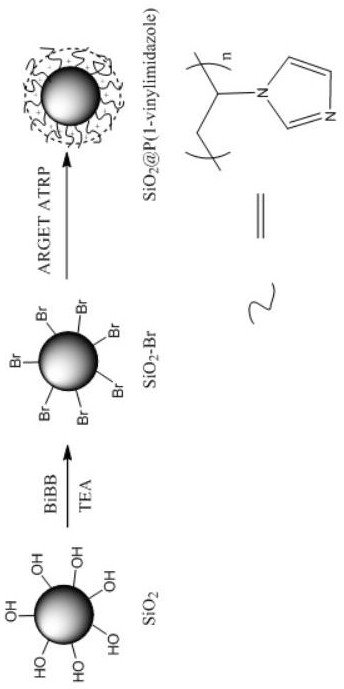

[0048] 2) Preparation of silica particles

[0049] Silica particles were prepared using the Störber method. 10 mL of TEOS was added dropwise to a mixed solution consisting of ethanol (200 mL), water (20 mL) and aqueous ammonia solution (6 mL). The solution was stirred and reacted at room temperature for 12...

Embodiment 2

[0056] A preparation method of a proton exchange membrane, comprising the following steps:

[0057] 1) Sulfonation of polyether ether ketone

[0058] 20 g of PEEK was dried in an oven at 105 °C overnight, and then dissolved in 200 mL of concentrated sulfuric acid at room temperature. After dissolving, the temperature was raised to 45 °C, and the reaction was carried out under vigorous stirring for 8 h. After the reaction, the reacted solution was poured into ice water, and the resulting precipitate was washed with deionized water to remove excess acid until the pH of the polymer was 7; the final product (SPEEK) was placed in an oven at 105°C Dry to constant weight.

[0059] 2) Preparation of silica particles

[0060] Silica particles were prepared using the Störber method. 10 mL of TEOS was added dropwise to a mixed solution consisting of ethanol (200 mL), water (20 mL) and aqueous ammonia solution (6 mL). The solution was stirred and reacted at room temperature for 6 h. A...

Embodiment 3

[0067] A preparation method of a proton exchange membrane, comprising the following steps:

[0068] 1) Sulfonation of polyether ether ketone

[0069] 20 g of PEEK was dried in an oven at 105 °C overnight, and then dissolved in 200 mL of concentrated sulfuric acid at room temperature. After dissolving, the temperature was raised to 45 °C, and the reaction was carried out under vigorous stirring for 72 h. After the reaction, the reacted solution was poured into ice water, and the resulting precipitate was washed with deionized water to remove excess acid until the pH of the polymer was 7.5; the final product (SPEEK) was placed in an oven at 105°C Dry to constant weight.

[0070] 2) Preparation of silica particles

[0071] Silica particles were prepared using the Störber method. 10 mL of TEOS was added dropwise to a mixed solution consisting of ethanol (200 mL), water (20 mL) and aqueous ammonia solution (6 mL). The solution was stirred at room temperature for 24 h. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com