Plant organic converting enzyme degradation agent as well as preparation and use methods thereof

A technology for converting enzymes and degrading agents, which is applied in the fields of botanical equipment and methods, plant growth regulators, fertilization methods, etc., can solve the problems of inability to reduce pesticide residues, and the effect of removing pesticide residues and heavy metals is not obvious, so as to reduce pesticide residues. and heavy metal content, promoting cell division and metabolism, and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

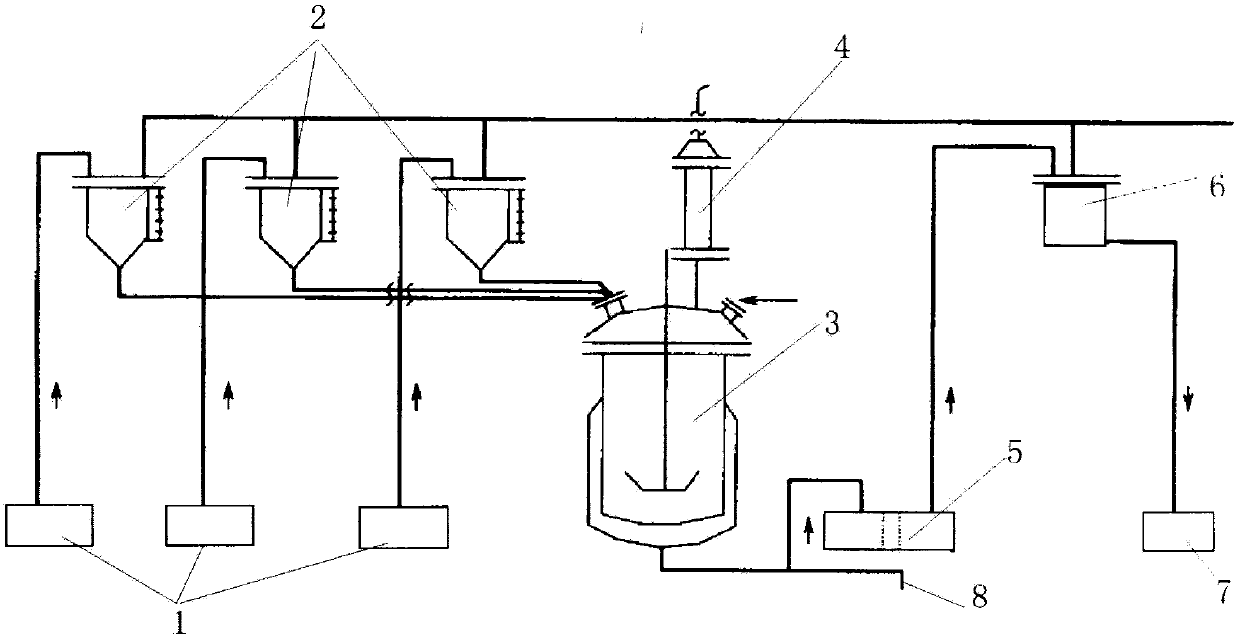

Method used

Image

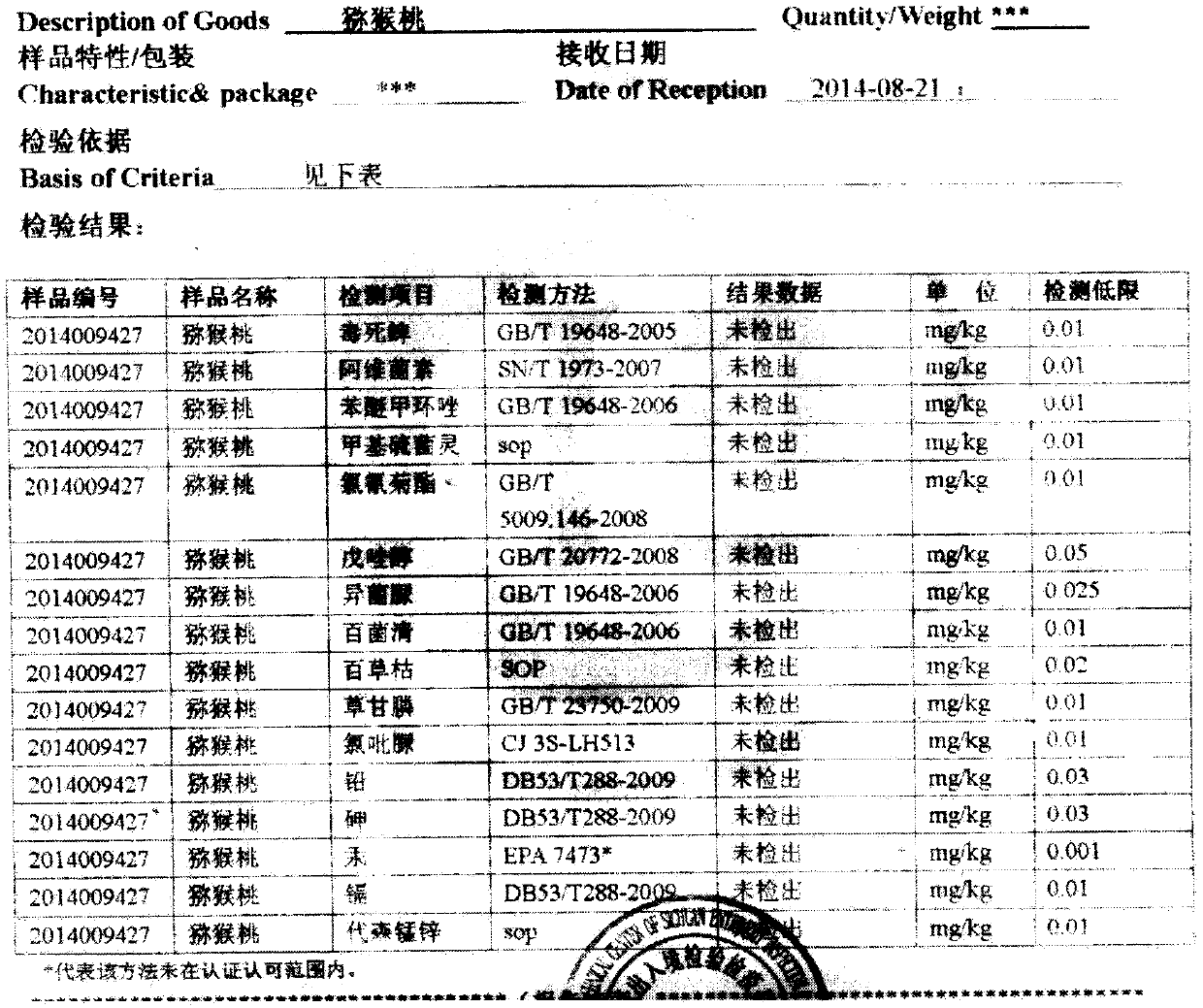

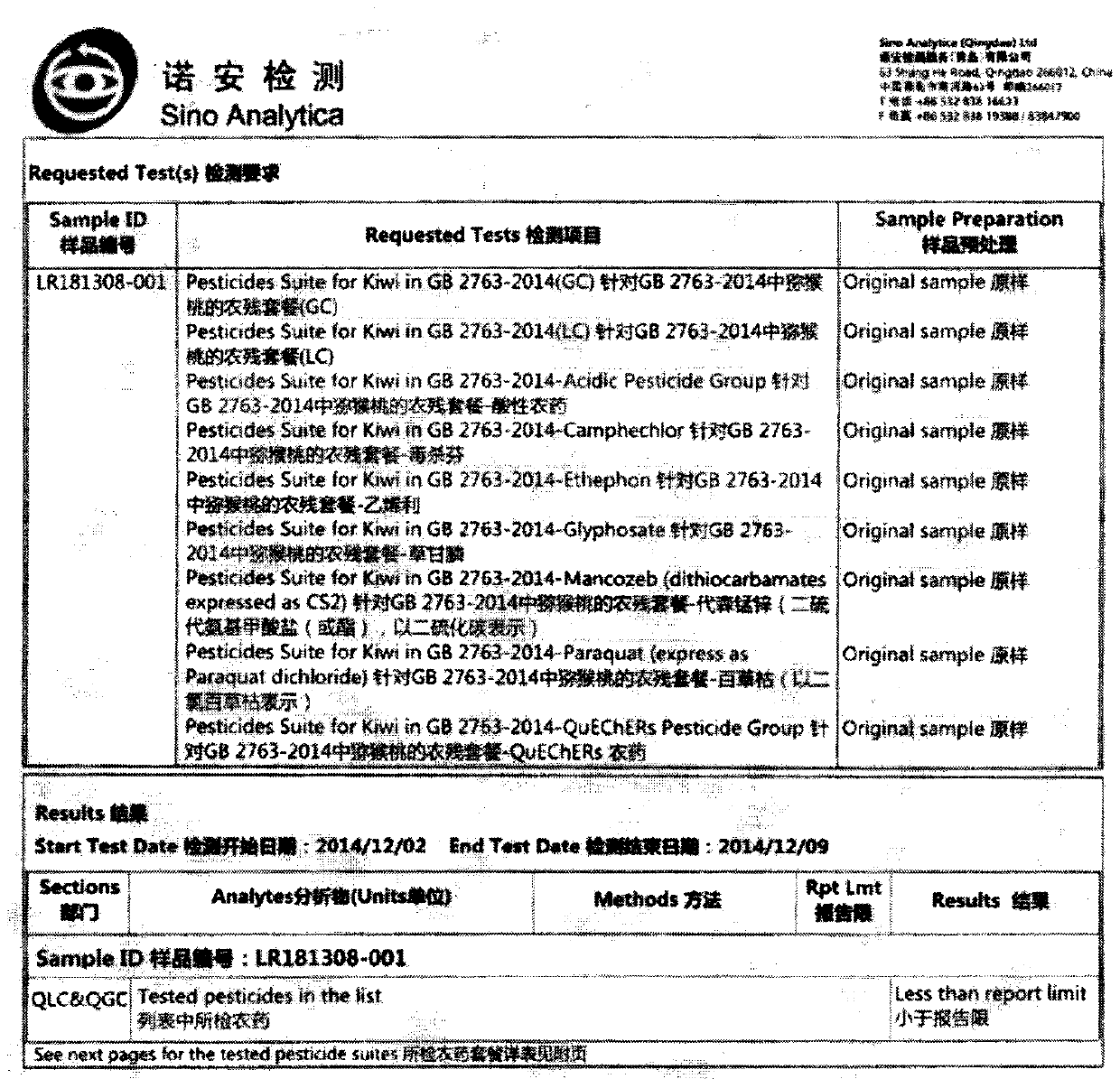

Examples

Embodiment 1

[0050] A plant organic conversion enzyme degradation agent, comprising the following raw materials in mass percentages:

[0051] Boric acid 0.51-0.61%,

[0052] Zinc chloride 0.50-0.56%,

[0053] Ammonium sulfate 1.43-1.58%,

[0054] Potassium dihydrogen phosphate 0.48-0.53%,

[0055] Potassium nitrate 3.05-3.37%,

[0056] Copper citrate 3.11-3.43%,

[0057] Glucose-6-phosphate dehydrogenase 0.27-0.29%,

[0058] Amino acid 13.55-14.98%,

[0059] Magnesium chloride 1.18-1.30%,

[0060] Manganese nitrate 2.30-2.50%,

[0061] Ferrous sulfate 0.14-0.16%,

[0062] Urea 0.48-0.53%,

[0063] Zinc sulfate 1.49-1.64%,

[0064] The balance is water.

[0065] Further optimization, the specific mass percentages of each raw material are as follows:

[0066] Boric acid 0.58%, zinc chloride 0.53%, ammonium sulfate 1.5%, potassium dihydrogen phosphate 0.5%, potassium nitrate 3.21%, copper citrate 3.27%, glucose-6-phosphate dehydrogenase 0.28%, amino acid 14.26%; magnesium chloride...

Embodiment 2

[0088] This embodiment is further optimized on the basis of Example 1. In this embodiment, the specific mass percentages of the raw materials of the plant organic converting enzyme degradation agent are as follows:

[0089]Boric acid 0.61%, zinc chloride 0.56%, ammonium sulfate 1.58%, potassium dihydrogen phosphate 0.53%, potassium nitrate 3.37%, copper citrate 3.43%, glucose-6-phosphate dehydrogenase 0.29%, amino acid 14.98%; magnesium chloride 1.30 %, manganese nitrate 2.50%, ferrous sulfate 0.16%, urea 0.53%, zinc sulfate 1.64%; the balance is water.

[0090] Wherein, the amino acid is composed of amino acid components according to the following proportions, aspartic acid 17.776%, threonine 5.058%, serine 5.772%, glutamic acid 23.754%, glycine 13.520%, alanine 4.455%, Cysteine 0.071%, Valine 3.842%, Methionine 0.042%, Isoleucine 2.030%, Leucine 2.622%, Tyrosine 0.876%, Phenylalanine 1.366%, Lysine 1.932 %, arginine 6.610%, and the balance is proline.

[0091] In this em...

Embodiment 3

[0093] This embodiment is further optimized on the basis of Example 1. In this embodiment, the specific mass percentages of the raw materials of the plant organic converting enzyme degradation agent are as follows:

[0094] Boric acid 0.51%, zinc chloride 0.50%, ammonium sulfate 1.43%, potassium dihydrogen phosphate 0.48%, potassium nitrate 3.05%, copper citrate 3.11%, glucose-6-phosphate dehydrogenase 0.27%, amino acid 13.55%; magnesium chloride 1.18 %, manganese nitrate 2.30%, ferrous sulfate 0.14%, urea 0.48%, zinc sulfate 1.49%; the balance is water.

[0095] Wherein, the amino acid is composed of amino acid components according to the following proportions, aspartic acid 17.776%, threonine 5.058%, serine 5.772%, glutamic acid 23.754%, glycine 13.520%, alanine 4.455%, Cysteine 0.071%, Valine 3.842%, Methionine 0.042%, Isoleucine 2.030%, Leucine 2.622%, Tyrosine 0.876%, Phenylalanine 1.366%, Lysine 1.932 %, arginine 6.610%, and the balance is proline.

[0096] Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com