Copper-composite molecular sieve catalyst used for synthesis of diethyl carbonate through gas-phase oxidative carbonylation and its preparation method

A composite molecular sieve and diethyl carbonate technology, which is applied in the direction of molecular sieve catalyst, carbonate/haloformate preparation, organic compound preparation, etc., can solve problems such as equipment corrosion, catalyst deactivation, chlorine loss, etc., to avoid Equipment corrosion issues, effects of optimal activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the Yβ carrier is as follows: add 4.5g of the template agent tetraethylammonium bromide (TEAB) into 8mL of 25% ammonia (density 0.91g / mL) solution, then add 1mL of water, stir to dissolve, and then Add 0.3g NaAlO 2 and 0.3g NaOH and 7.5mL H 2 After O was stirred until completely dissolved, 13g of silica sol (SiO 2 The mass fraction is 30%) and 2mL H 2 O, a suspension was formed after vigorous stirring for 1 h, in which the n(SiO 2 ) / n(Al 2 o 3 )=36, n(NH 3 +NaOH) / n(SiO 2 )=1.8. Then add 2g of commercially available NaY molecular sieve powder (Nankai Catalyst Factory, n(SiO 2 ) / n(Al 2 o 3 )=5) and 25mL H 2 O, stirred for 0.5h, then moved to a crystallization kettle, hydrothermally crystallized at 140°C for 180h, after the crystallization was completed, filtered and washed until the filtrate was neutral. After drying at 120°C for 8 hours, put it into a muffle furnace to raise the temperature to 590°C at a rate of 2°C / min, keep the tem...

Embodiment 2-4

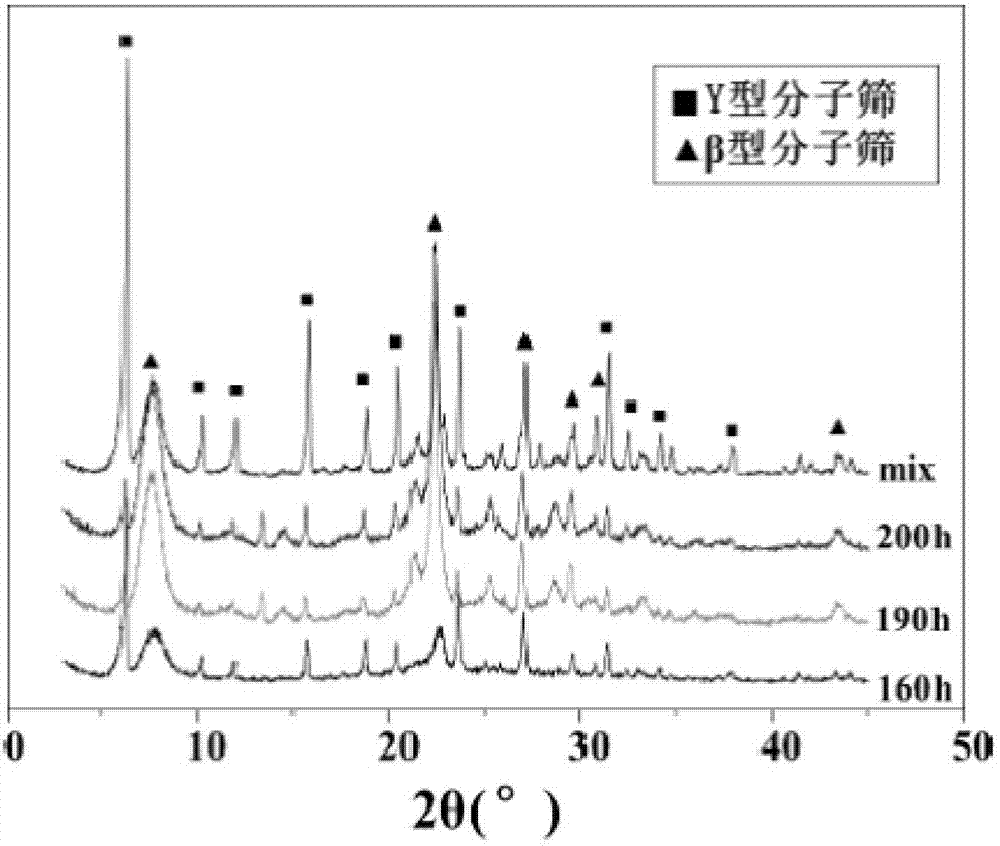

[0026] In the case that other experimental conditions are exactly the same as in Example 1, the crystallization time in the preparation process of the sodium-type Yβ composite molecular sieve is changed to 160h, 190h, and 200h, wherein the mix state refers to the situation of Comparative Example 1, that is, the two molecular sieves Condition after physical mixing. The XRD spectrogram of the NaYβ molecular sieve that it obtains and the NaY-β molecular sieve that physically mixes is as follows figure 1 As shown (XRD adopts the Rigaku D / max2500v / pc diffractometer of Japan Rigaku, and uses Cu / K-alphal rays as the light source for measurement. The target is a copper target, the 2θ angle measurement range is 20~80°, and the scanning speed is 8° / min, the test samples are all powder, the same below). When the crystallization time is longer than 160h, the crystal phases of Y and β molecular sieves can appear at the same time, indicating that the composite molecular sieve has been suc...

Embodiment 5-7

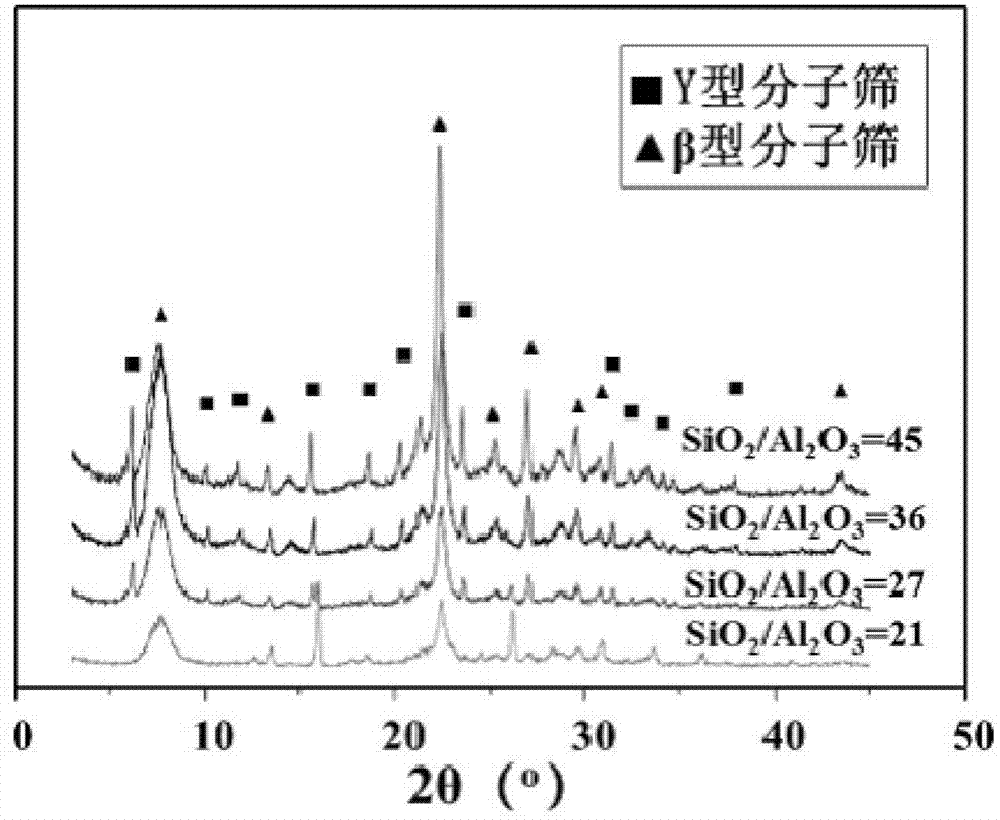

[0028] In the case that other experimental conditions are exactly the same as in Example 1, change the NaAlO added in the system of the β molecular sieve in the preparation process of the NaYβ composite molecular sieve 2 The mass of SiO, i.e. changing the 2 / Al 2 o 3 The ratio n(SiO 2 ) / n(Al 2 o 3 )=21, 27, 45. The XRD spectrogram of the NaYβ molecular sieve that it obtains and example 1 is as figure 2 shown. When n(SiO 2 ) / n(Al 2 o 3) ratio between 21 and 45, NaYβ composite molecular sieves can be successfully synthesized, and the higher the ratio, the higher the proportion of β crystal phase in the composite molecular sieve. Therefore, by controlling the SiO 2 / Al 2 o 3 The ratio of the β molecular sieve can change the proportion of the crystal phase in the composite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com