Foamy copper in-situ growth copper oxide/cuprous oxide photocatalytic material as well as preparation method and application thereof

A photocatalytic material and in-situ growth technology, applied in the field of photocatalysis, can solve the problem that powder photocatalysts are not easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a copper oxide / cuprous oxide photocatalytic material grown in situ on foamed copper, comprising the following steps:

[0038] S1. Cut the foamed copper into flakes, put them in absolute ethanol, acetone, and deionized water for ultrasonic treatment, and soak in 0.1-1M hydrochloric acid for 5-20 minutes; obtain a cleaned foamed copper sheet;

[0039] S2, dissolving NaOH in deionized water to obtain solution A; adding NaCl to solution A to obtain solution B, the molar mass ratio of NaOH to NaCl is 1-5;

[0040] S3. Add 0.1-2 g / L of polyethylene glycol (PEG), a dispersant with a relative molecular mass of 400, to solution B to obtain solution C;

[0041] S4, adjust the output parameters of the three constant electrophoresis instrument, the control current is 5 ~ 30mA, the voltage is 5 ~ 50V, the inert electrode is used as the cathode, the foamed copper prepared in step S1 is used as the anode, and the solution C prepared in ste...

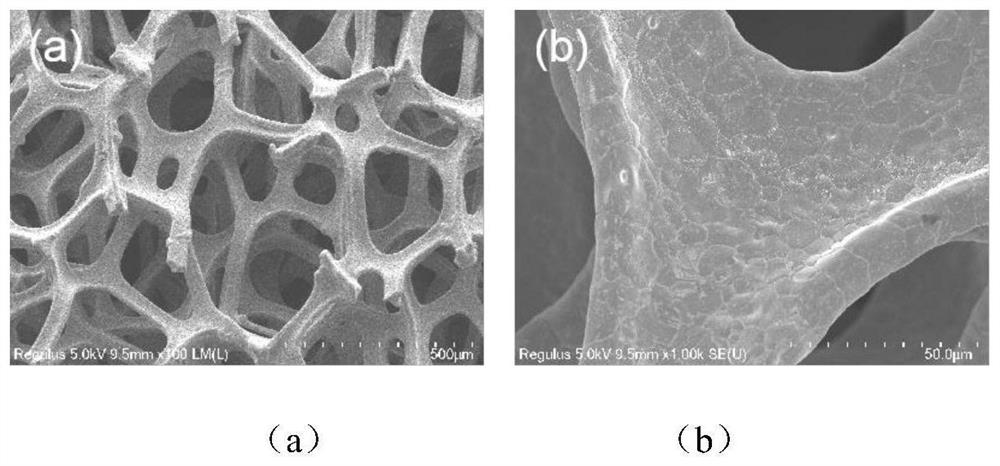

Embodiment 1

[0048] (1) Cut the foamed copper into a sheet-like structure, put it into absolute ethanol, acetone, and deionized water for ultrasonic treatment for 5 minutes, and soak in 1.0M hydrochloric acid for 5 minutes to obtain some clean foamed copper;

[0049] (2) 1M NaOH was dissolved in 300ml deionized water to obtain solution A;

[0050] (3) Dissolve 2.5M NaCl in solution A, stir for 20 min to obtain solution B containing NaOH and NaCl, then add 0.1 g / L PEG with a relative molecular mass of 400 to solution B and continue stirring for 30 min to obtain solution C.

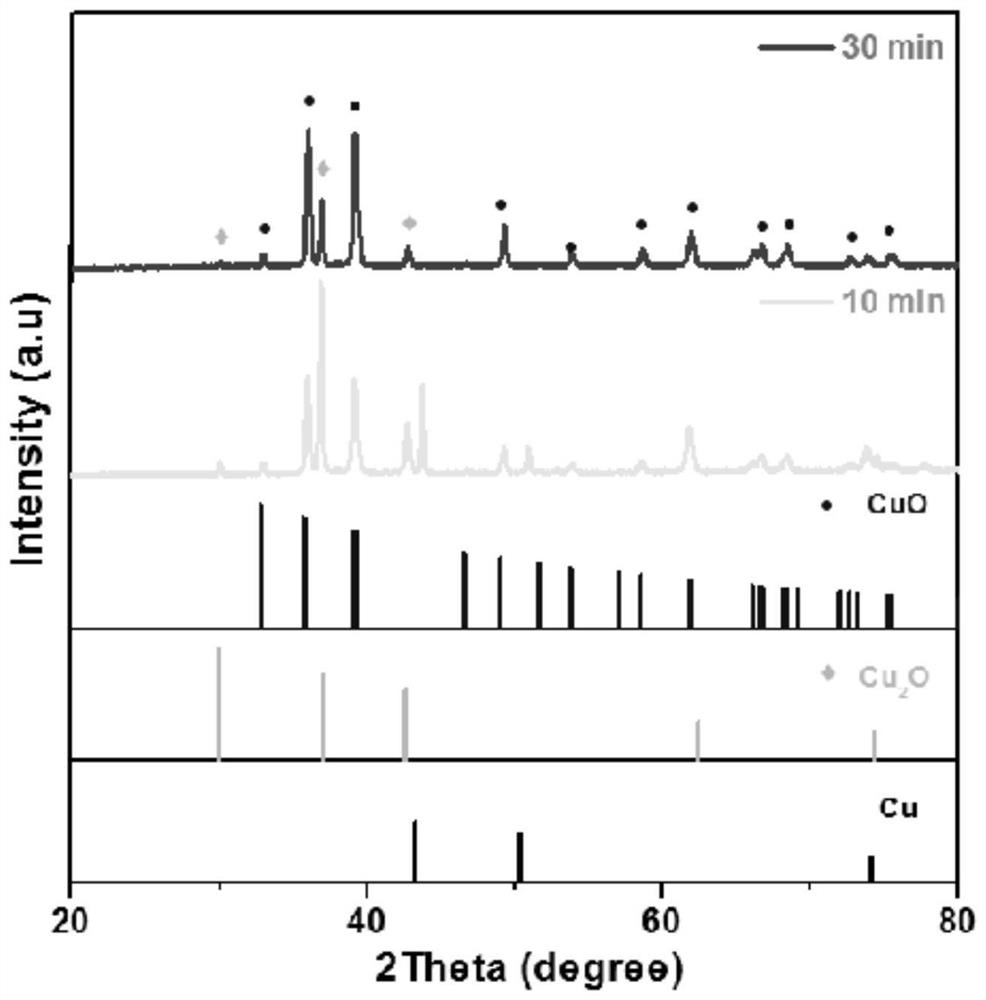

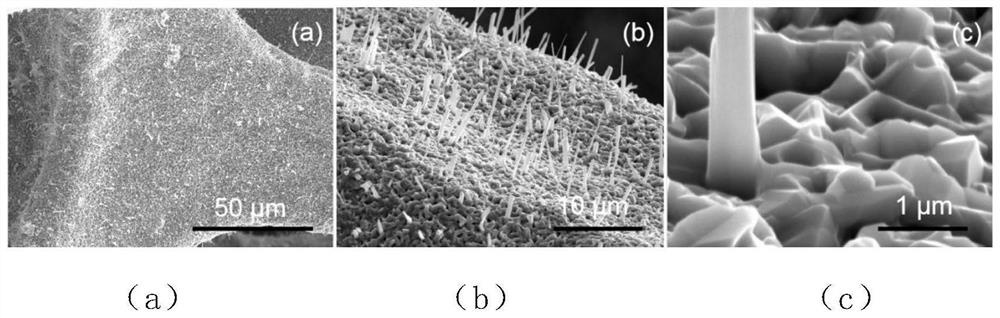

[0051] (4) Adjust the output parameters of the three-constant electrophoresis instrument, use a constant current output of 10mA, use graphite as the cathode, foam copper as the anode, solution C as the electrolyte, and anodize for 10 minutes. Product D was obtained after repeated washing with deionized water for anodic oxidation;

[0052] (5) Place the product D in a muffle furnace, anneal at 200°C, raise the temperatu...

Embodiment 2

[0054] (1) Cut the foamed copper into a sheet-like structure, put it into absolute ethanol, acetone, and deionized water for ultrasonic treatment for 5 minutes respectively, and soak in 1M hydrochloric acid for 5 minutes to obtain some clean foamed copper;

[0055] (2) 1M NaOH was dissolved in 300ml deionized water to obtain solution A;

[0056] (3) Dissolve 2.5M NaCl in solution A, stir for 20 min to obtain solution B containing NaOH and NaCl, then add 0.5 g / L PEG with a relative molecular mass of 400 to solution B and continue stirring for 30 min to obtain solution C.

[0057] (4) Adjust the output parameters of the three-constant electrophoresis instrument, with a constant current output of 10mA, graphite as the cathode, foamed copper as the anode, solution C as the electrolyte, and anodize for 30 minutes. Product D was obtained after repeated washing with deionized water for anodic oxidation;

[0058] (5) Place the product D in a muffle furnace, anneal at 250°C, raise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com