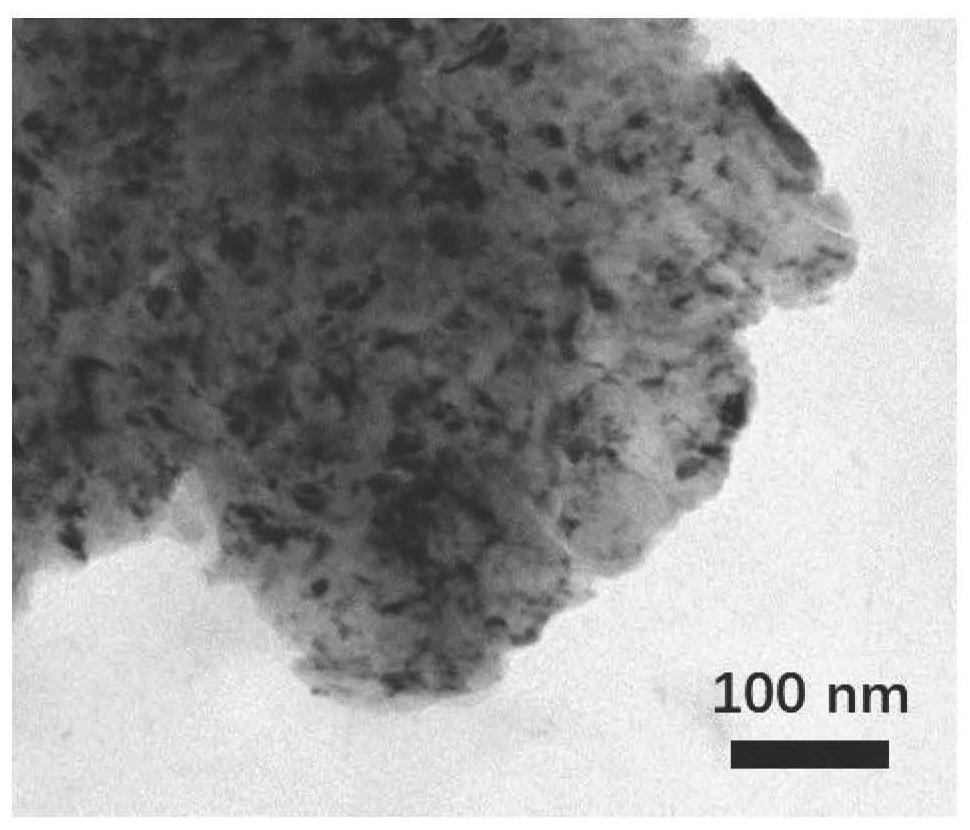

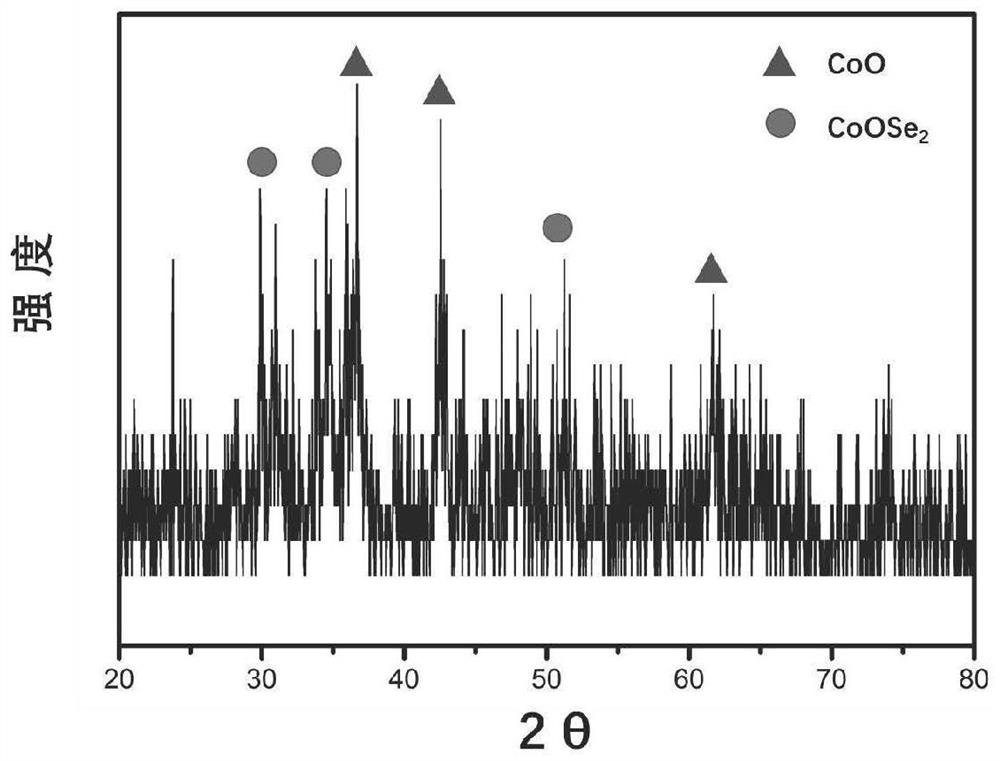

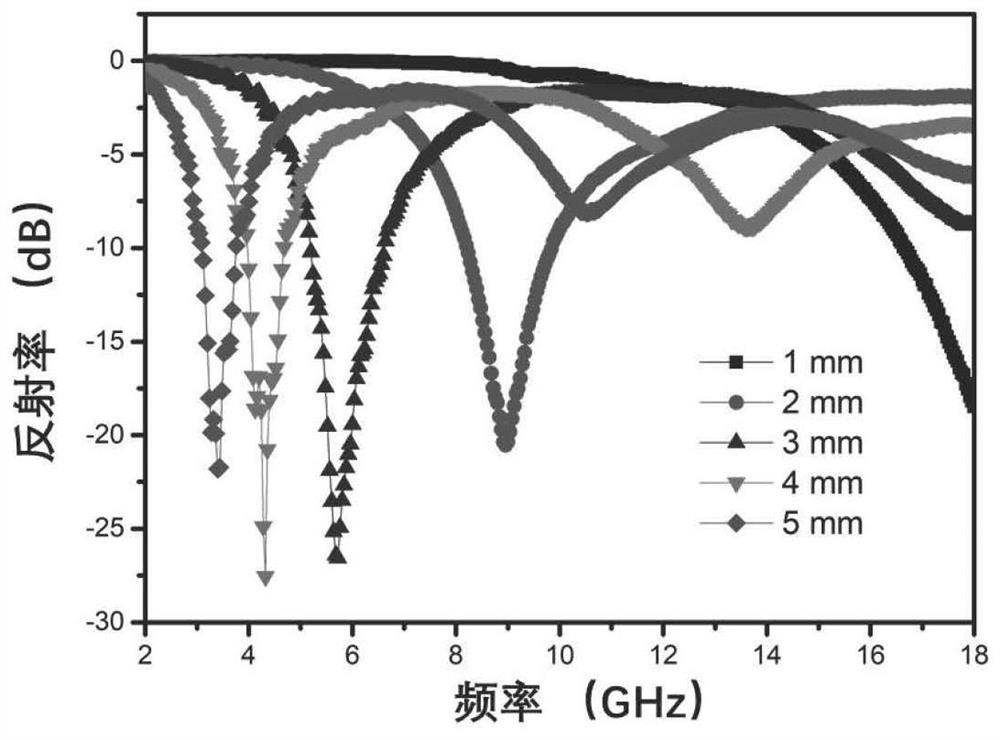

A preparation method of cobalt oxide/cobalt diselenide heterostructure loaded carbon three nitrogen four composite material

A heterogeneous structure, cobalt diselenide technology, applied in the direction of cobalt oxide/cobalt hydroxide, nickel oxide/nickel hydroxide, chemical instruments and methods, etc., can solve the problems of high cost, affecting large-area use, etc. Uniformity, high mobility, and singular mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a cobalt oxide / cobalt diselenide heterostructure loaded C3N4 composite material is completed according to the following steps:

[0037] 1. Disperse the Se powder in the octadecene by an ultrasonic disperser to obtain an organic solvent dispersion of the Se powder. The mass fraction of Se powder in the Se powder-octadecene solution is 10%, and the dispersion time is 60 min;

[0038] Second, the g-C 3 N 4 Disperse into ethanol, then disperse into octadecene, heat to remove ethanol. The g-C 3 N 4 The mass fraction is 1%; the volume ratio of ethanol and octadecene is 1:2;

[0039] 3. Disperse the cobalt source in oleylamine to obtain a cobalt dispersion solution; the cobalt source is cobalt acetate. The mass fraction of cobalt acetate is 10%;

[0040] 4. ①Heating the Se powder solution to 80°C to obtain reaction solution I;

[0041] ② Put g-C 3 N 4 Heat the dispersion to 80°C to obtain reaction solution II;

[0042] ③ Heating the cobalt ac...

Embodiment 2

[0049] A preparation method of a cobalt oxide / cobalt diselenide heterostructure loaded C3N4 composite material is completed according to the following steps:

[0050] 1. Disperse the Se powder in octadecene through an ultrasonic disperser to obtain an organic solvent dispersion of Se powder. The mass fraction of Se powder in the Se powder-octadecene solution is 10%, and the dispersion time is 60 min;

[0051] Second, the g-C 3 N 4 Disperse into ethanol, then put the dispersion into octadecene, and remove the ethanol by heating. The g-C 3 N 4 The mass fraction is 1%; the volume ratio of ethanol and octadecene is 1:2;

[0052] 3. Disperse the cobalt source in oleylamine to obtain a cobalt dispersion solution; the cobalt source is cobalt acetate. The mass fraction of cobalt acetate is 10%;

[0053] 4. ①Heating the Se powder solution to 80°C to obtain reaction solution I;

[0054] ② Put g-C 3 N 4 Heat the dispersion to 80°C to obtain reaction solution II;

[0055] ③ Hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com