Environmentally-friendly cross-linked acrylate polymer emulsion and preparation method thereof

A technology of polymer emulsion and acrylate, which is applied in the field of environment-friendly cross-linked acrylate polymer emulsion and its preparation, can solve the problems of large environmental pollution, poor biodegradability, and application restrictions, so as to broaden the application field and improve performance, excellent environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 250mL four-neck flask equipped with a stirrer, reflux condenser, and dropping funnel, add 0.50g sodium myristoyl sarcosinate, 1.00g alkyl polyglycoside, 1.05g sodium bicarbonate and 60.00g deionized water , stirred and heated to 80°C in a water bath. Add 10% of the mixed monomer and 10% of the initiator solution dropwise within 15 minutes, and continue to keep warm for 15 minutes after the dropwise addition is completed. Then the remaining initiator emulsion and mixed monomers were added dropwise into the four-necked flask within 3.0 hours. After the dropwise addition was completed, the temperature was raised to 90° C., and the temperature was continued for 40 minutes. The temperature was lowered to 40°C, the pH value was adjusted with ammonia water, and the environmentally friendly polymer emulsion was obtained after filtering and discharging. Wherein the composition of the mixed monomer is 30.00g of butyl acrylate, 22.50g of methyl methacrylate, 3.20g of hydroxy...

Embodiment 2

[0038] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 1.00g of sodium lauroyl sarcosinate, 0.48g of alkyl polyglycosides, 0.70g of sodium bicarbonate and 40.00g of deionized water, Stir and warm to 80°C in a water bath. Add 10% of the mixed monomer and 10% of the initiator solution dropwise within 15 minutes, and continue to keep warm for 15 minutes after the dropwise addition is completed. Then the remaining initiator emulsion and mixed monomers were added dropwise into the four-necked flask within 3.0 hours. After the dropwise addition was completed, the temperature was raised to 90° C., and the temperature was continued for 40 minutes. The temperature was lowered to 40°C, the pH value was adjusted with ammonia water, and the environmentally friendly polymer emulsion was obtained after filtering and discharging. Wherein the composition of the mixed monomer is 20.00g of butyl acrylate, 15.00g of methyl methacrylate; the c...

Embodiment 3

[0040]In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 0.60g sodium lauroyl glutamate, 1.20g alkyl polyglycosides, 1.20g sodium bicarbonate and 110.00g of deionized water, Stir and warm to 80°C in a water bath. Add 10% of the mixed monomer and 10% of the initiator solution dropwise within 15 minutes, and continue to keep warm for 15 minutes after the dropwise addition is completed. Then the remaining initiator emulsion and mixed monomers were added dropwise into the four-necked flask within 3.0 hours. After the dropwise addition was completed, the temperature was raised to 90° C., and the temperature was continued for 40 minutes. The temperature was lowered to 40°C, the pH value was adjusted with ammonia water, and the environmentally friendly polymer emulsion was obtained after filtering and discharging. Wherein the composition of the mixed monomer is 35.00g of butyl acrylate, 20.00g of methyl methacrylate and 3.00g of itac...

PUM

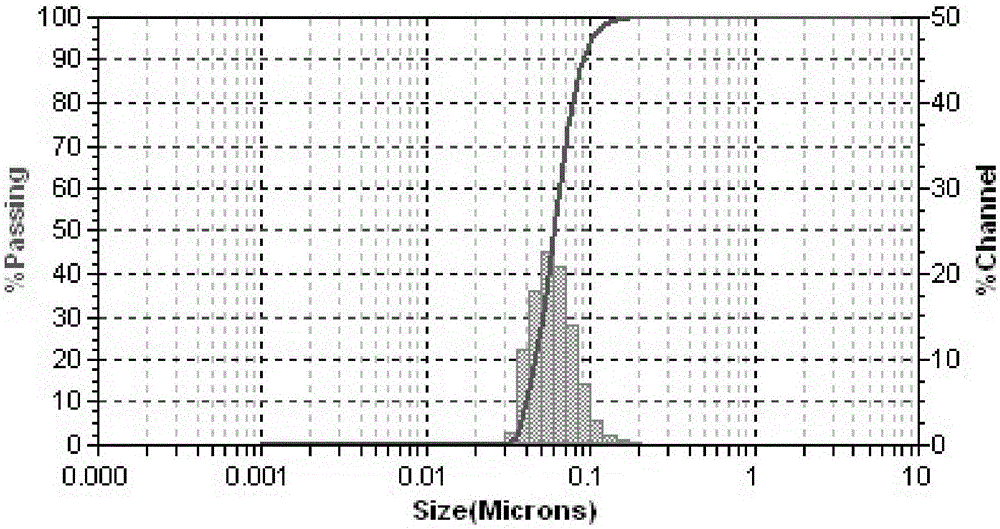

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com