Method and device for removing nitrogen

A technology of ammoniacal nitrogen and raw water, applied in the direction of chemical instruments and methods, biochemical equipment and methods, enzymes, etc., can solve the problems of non-methods and equipment large-scale operation cost increase, and achieve the effect of effective denitrification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the nitrogen removal method and device of the present invention will be described according to the accompanying drawings.

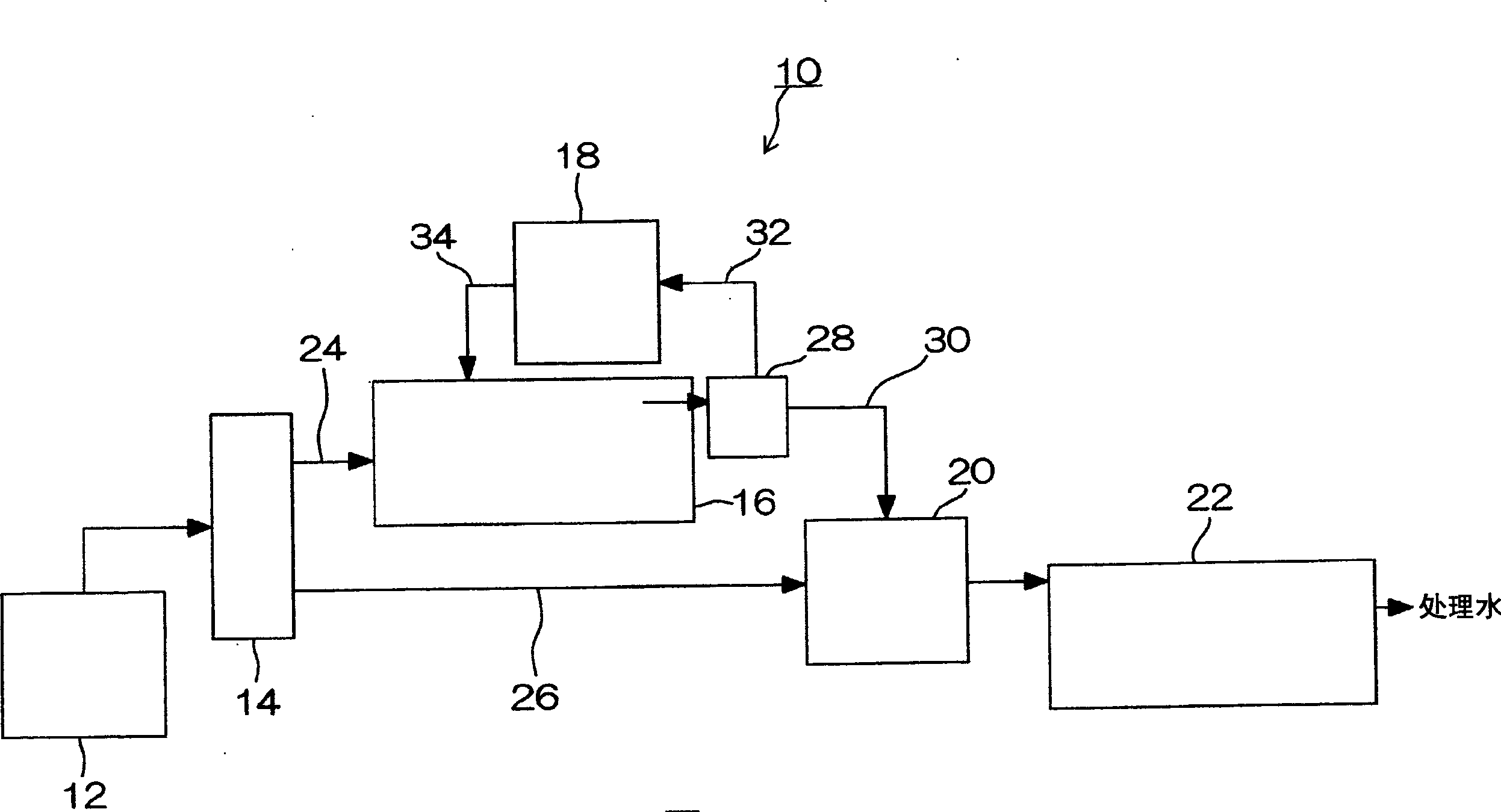

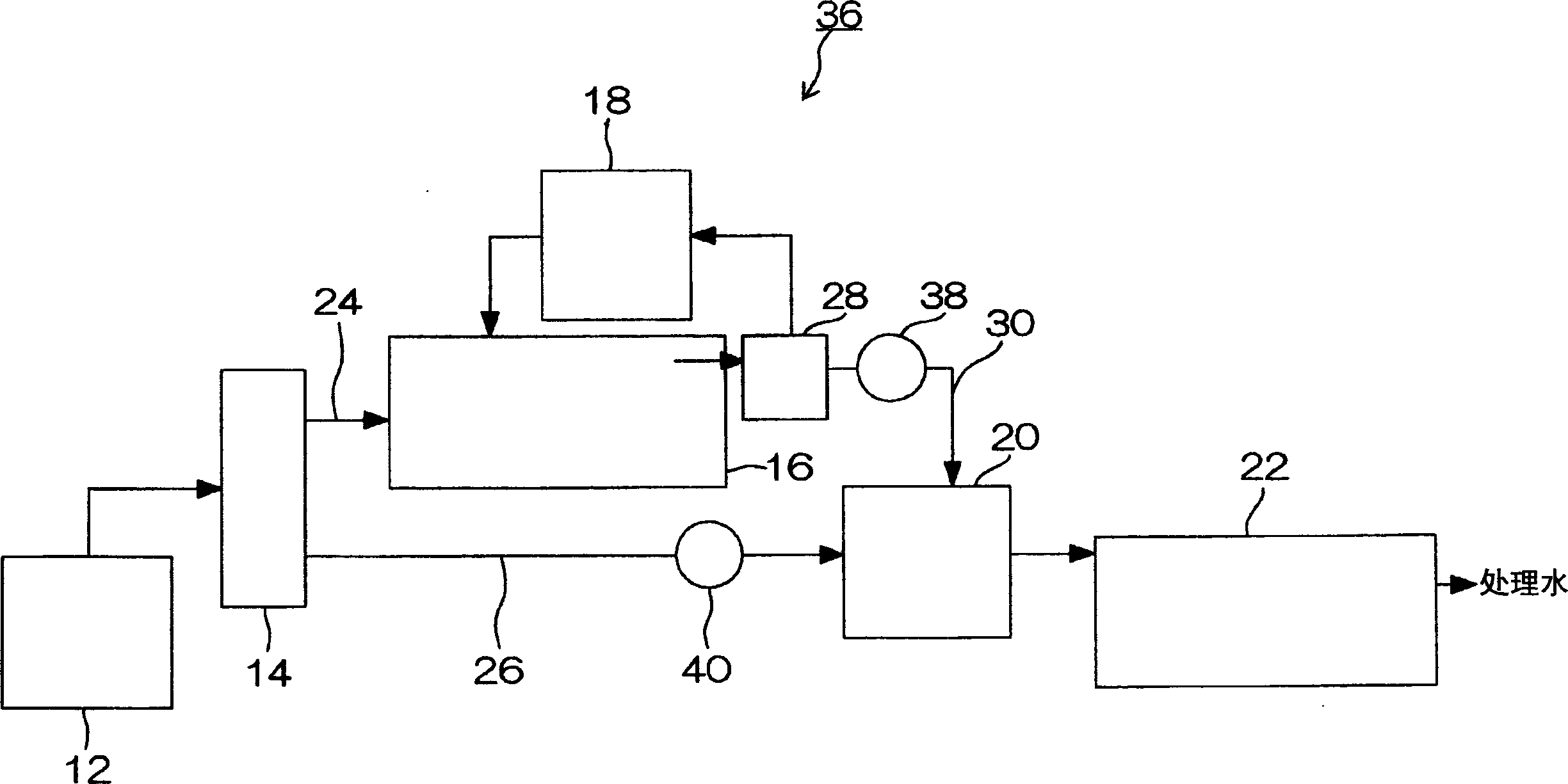

[0027] figure 1 It is a schematic diagram showing the structure of Embodiment 1 of the nitrogen removal device of the present invention.

[0028] Such as figure 1 As shown, the nitrogen removal device 10 of Embodiment 1 is mainly composed of a raw water tank 12, a distribution tank 14, a nitrification tank 16, a heat treatment tank 18, a mixing tank 20 and an anammox device 22, and is stored in the raw water tank 12. The raw water is sent to distribution tank 14.

[0029] A first infusion line 24 and a second infusion line 26 are connected to the distribution tank 14 . The distribution tank 14 distributes the raw water at a predetermined flow ratio and sends it to the first infusion line 24 and the second infusion line 26 . For example, the ratio of the flow rate of the raw water flowing through the first infusion line 24 to the flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com