Dual-mode multi-beam electronic gun for dual-mode traveling wave tube and method for controlling dual-mode multi-beam electronic gun

A dual-mode traveling wave tube and dual-mode technology, applied to the electron/ion gun of the time-of-flight electron tube, the cathode of the time-of-flight electron tube, etc., can solve the problems of restricting technological development and not fully complying with the dual-mode electron gun , to achieve the effect of simplified process, easy processing and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

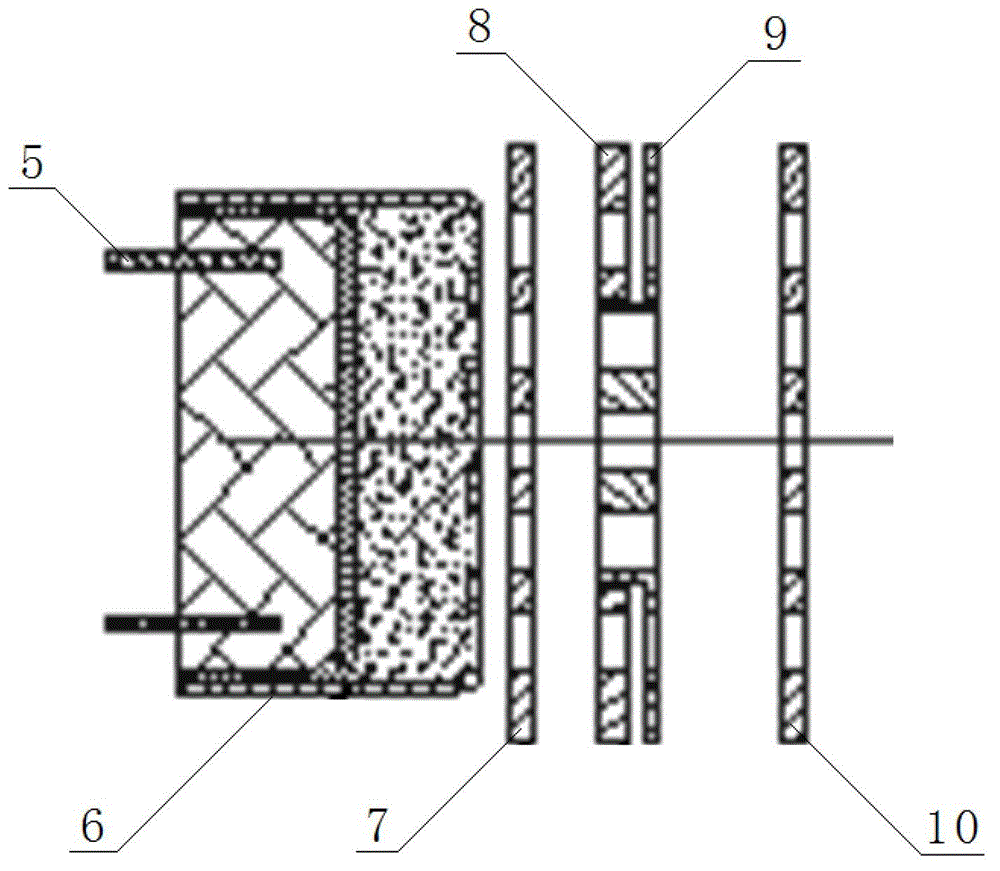

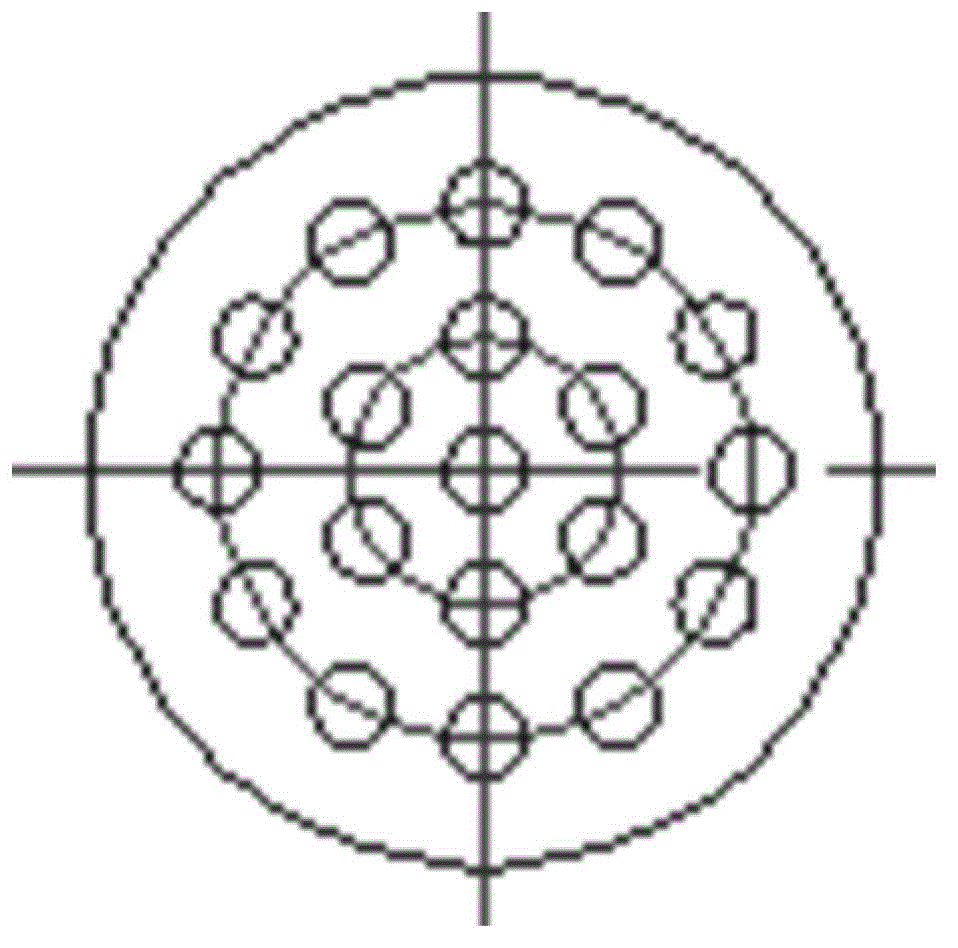

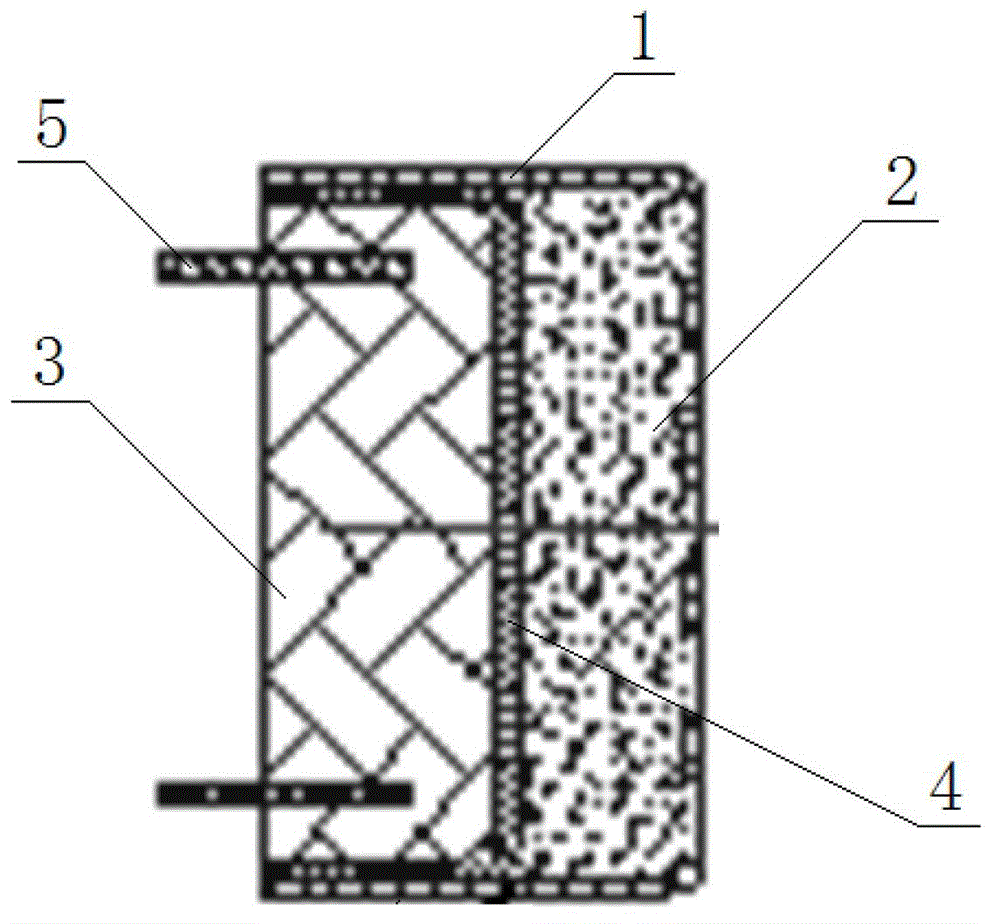

[0034] Depend on Figure 1-12 Combining the shown structures, it can be seen that this dual-mode multi-injection electron gun for dual-mode traveling wave tubes includes sequentially arranged cathodes 6, shadow grids 7, inner grids 8, outer grids 9 and anodes 10; the cathode 6 includes cathode molybdenum Cylinder 1, the cathode molybdenum cylinder 1 is divided into two parts along the axis of the cathode molybdenum cylinder 1, the two parts are separated by insulating ceramics 4, a cathode sponge 2 is installed in one part, and a filament potting is installed in the other part An insulator 3, and a filament potting insulator 3 is provided with a filament 5; the end face of the cathode molybdenum cylinder 1 is provided with several holes, the inner grid 8 controls the electron beam in a part of the holes, and the outer grid 9 controls the electron beam in the remaining holes. The electron beam realizes dual-mode operation.

[0035] The diameter of the holes on the end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com