Sodium ion battery anode material and sodium iron battery comprising anode material

A technology of sodium ion battery and cathode material, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low sodium storage capacity, poor stability, poor rate performance, etc., and achieve high sodium storage capacity and good stability. , the effect of excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

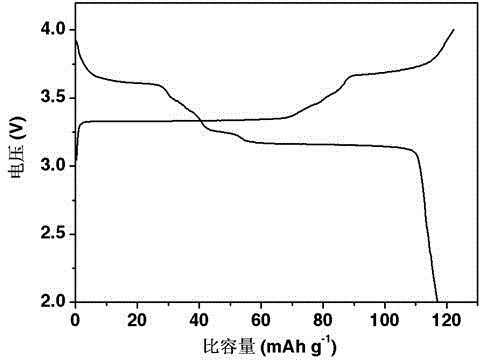

[0030] 0.15 mol Na 2 CO 3 , 0.2 mol NiO and 0.05 mol Sb 2 o 3 Mixed, placed in a high-energy ball mill jar, high-energy ball milled for 4 hours, and then the mixture was calcined at 800°C for 12 hours to prepare Na 3 Ni 2 SbO 6 . Na 3 Ni 2 SbO 6 Mix with acetylene black (10 wt%) high energy ball mill for 30min to get Na 3 Ni 2 SbO 6 / C cathode material. The positive electrode material was uniformly mixed with vinylidene fluoride (PVDF) and acetylene black in a weight ratio of 7:2:1, and coated on aluminum foil to form an electrode film. With the electrode film as the working electrode and the metal sodium sheet as the counter electrode, 1mol L -1 NaPF 6 (The solvent is a mixture of EC and DEC, and the volume ratio of EC and DEC is 1:1). The electrolyte was assembled into a 2016-type coin cell for electrochemical testing. figure 1 Its constant current charge and discharge curve (0.1 C (20mA g -1 ) current density, charging and discharging in the range of 2-4.0 ...

Embodiment 2

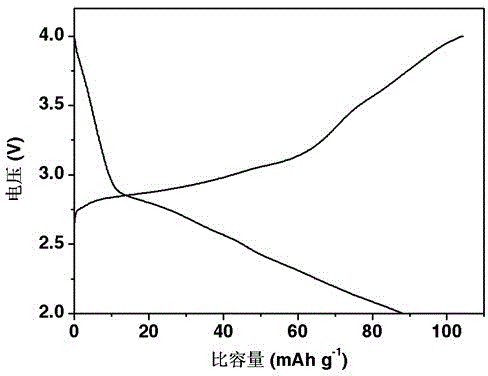

[0032] 0.15 mol Na 2 CO 3 , 0.1 mol Co 2 o 3 and 0.05 mol Sb 2 o 5 , placed in a high-energy ball mill jar, high-energy ball milled for 4 hours, and then calcined at 900°C for 24 hours to prepare Na 3 co 2 SbO 6 . Na 3 co 2 SbO 6 Mix with Super P (20 wt%) planetary ball mill for 6h to get Na 3 co 2 SbO 6 / C cathode material.

[0033] Prepare electrode film by the method in embodiment 1 and carry out constant current charge and discharge test to it, figure 2 Its constant current charge and discharge curve (0.1 C (20mA g -1) current density and charge and discharge in the range of 2-4.0 V), it can be seen from the figure that the first cycle discharge capacity of the material is 88 mAh g -1 .

Embodiment 3

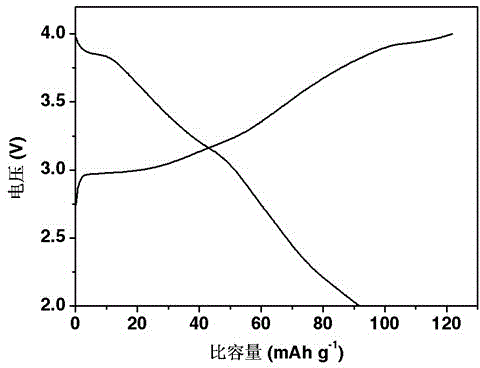

[0035] 0.15 mol Na 2 CO 3 , 0.05 mol Co 2 o 3 , 0.1 mol NiO and 0.05 mol Sb 2 o 3 , placed in a high-energy ball mill jar, high-energy ball milled for 6 hours, and then calcined at 1200°C for 6 hours to prepare Na 3 CoNiSbO 6 . Na 3 CoNiSbO 6 Mix with Ketjen black (5 wt%) planetary ball mill for 6h to get Na 3 CoNiSbO 6 / C cathode material.

[0036] Electrode film is prepared according to the method in embodiment 1 and is tested for row constant current charge and discharge, image 3 For this reason, the charge-discharge curve of the material at a current density of 0.1 C (20mA / g) shows that the discharge specific capacity of this material in the first week is 90 mAh g -1 , has a high sodium storage capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com