Preparation method of carbon electrode material and carbon electrode material

A carbon electrode and spinning technology, which is applied to the preparation of carbon electrode materials and the field of carbon electrode materials, can solve the problems of unsatisfactory fast charging performance, unfavorable industrial production, and difficulty in intercalation of sodium ions, and achieves excellent initial charging capacity and deintercalation. The effect of stable capacity and high sodium ion intercalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

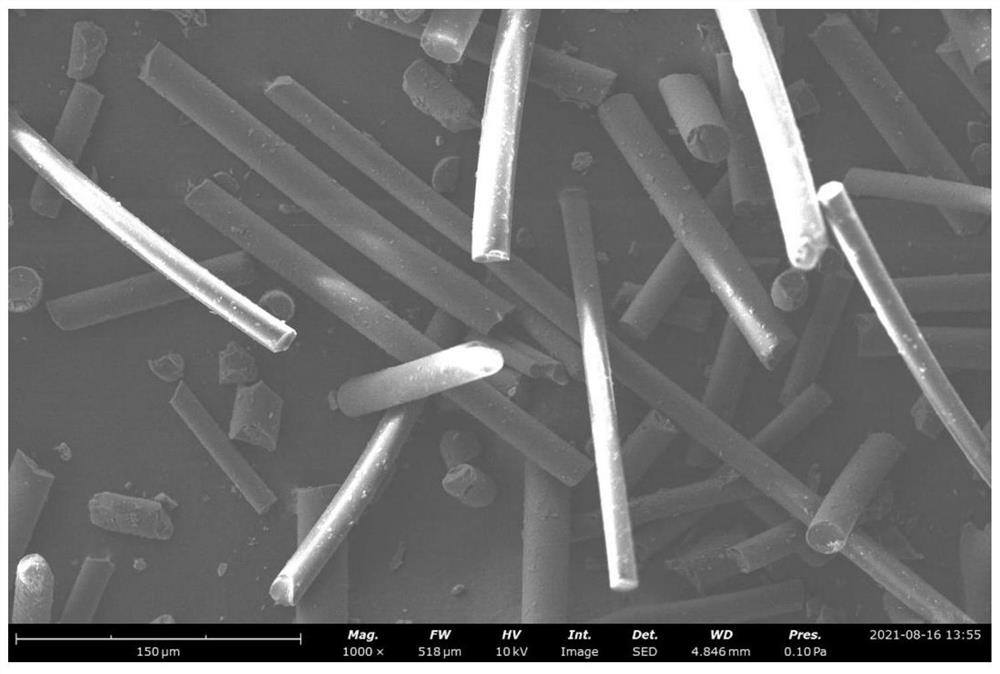

[0075] ① Spinning and curing to prepare fiber raw materials

[0076] The commercially available petroleum pitch with a softening point of 270°C was used as the precursor, and no other ingredients were added. The asphalt was heated to 320°C to melt, and was continuously spun by means of melt pump extrusion. The spinneret single plate was arranged in a single row with 200 holes, made of 304 stainless steel, the hole diameter was 100 μm, and the propulsion rate was 600mL / h. The diameter of the obtained fiber is 18 μm, and it is a continuous cylindrical fiber, and the fiber is straight and has no crimp. The obtained fiber is cured in a curing bath, the curing bath is hot air, and the hot air flow rate is 0.1m 3 / Kg, through 5 temperature zones of 280°C, 300°C, 320°C, 340°C, and 370°C, each temperature zone is 1.2 meters, the residence time is 0.6 hours, and the total residence time of the curing bath is 3 hours. After passing through the curing bath, the asphalt continuous fiber...

Embodiment 2

[0080] Using commercially available petroleum asphalt with a softening point of 270°C, adding a single-walled carbon nanotube-nitrogen methyl pyrrolidone dispersion with a content of 0.4wt% as a precursor , and then heated to 320°C and homogenized at high speed for 30 minutes with a homogenizer as a spinning solution. Others are carried out according to the method of Example 1.

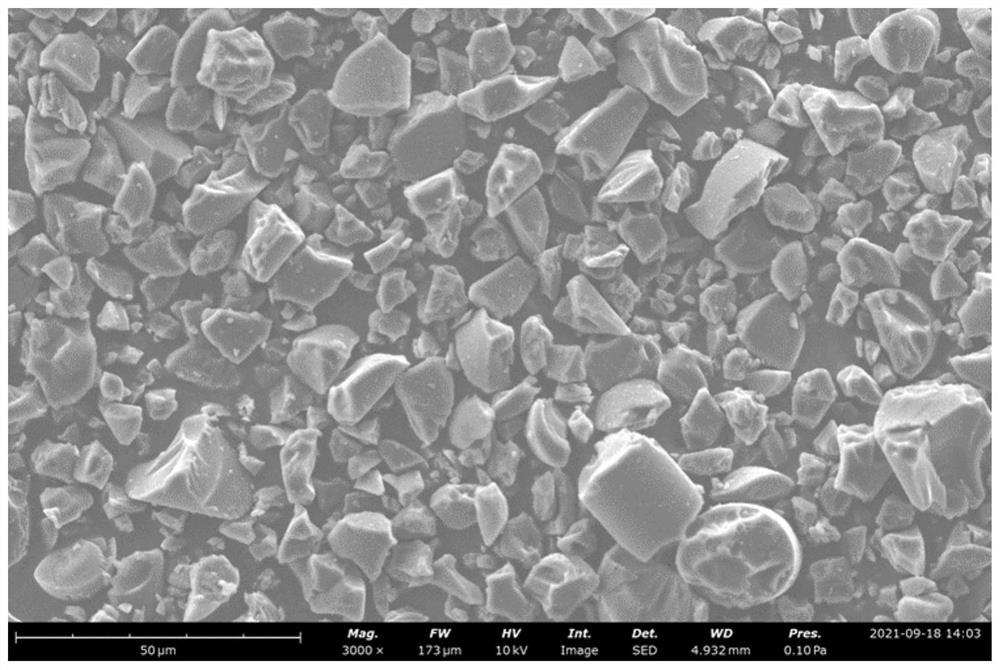

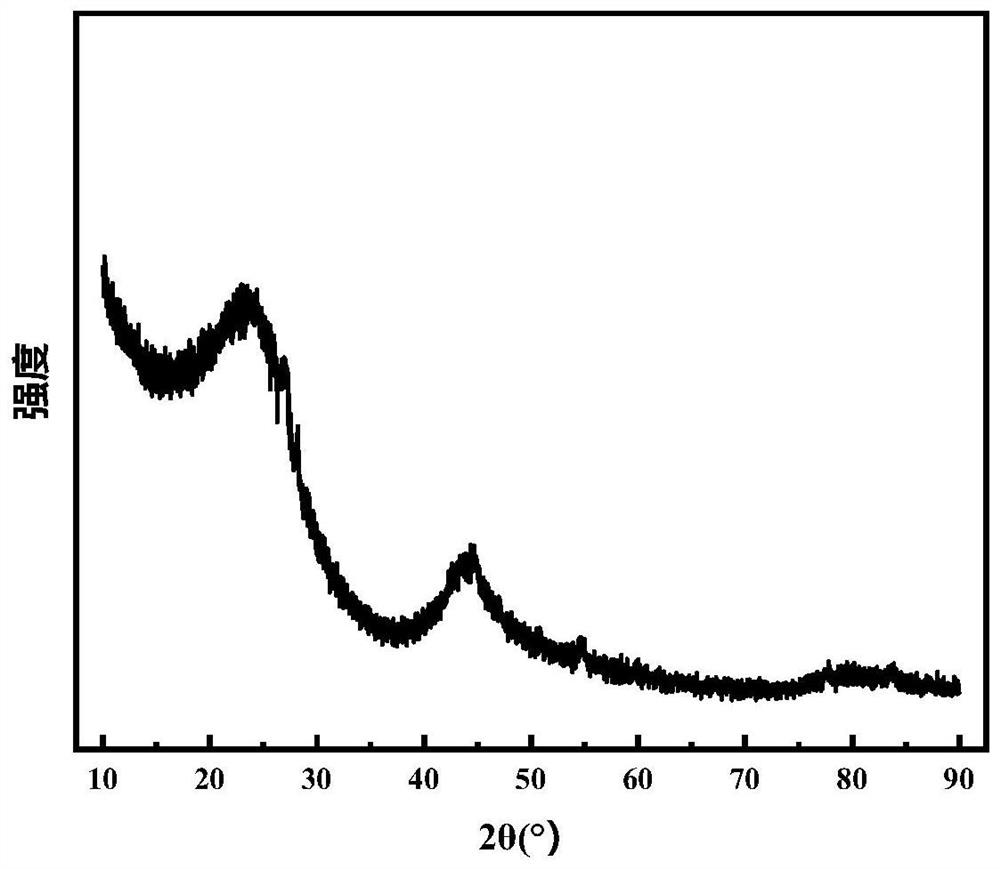

[0081] It can be seen from the XRD pattern that the obtained carbon electrode material is amorphous carbon.

Embodiment 3

[0083] ① Spinning and curing to prepare fiber raw materials

[0084] The commercially available petroleum pitch with a softening point of 270°C was used as the precursor, and no other ingredients were added. The asphalt was heated to 320°C to melt, and was continuously spun by means of melt pump extrusion. The spinneret single plate was arranged in a single row with 200 holes, made of 304 stainless steel, the hole diameter was 100 μm, and the propulsion rate was 400mL / h. The diameter of the obtained fiber was 18 μm, and it was a continuous cylindrical straight fiber. The obtained fiber is cured in a curing bath, the curing bath is hot air, and the hot air flow rate is 0.1m 3 / Kg, through 5 temperature zones of 280°C, 300°C, 330°C, 350°C, and 370°C, each temperature zone is 1.2 meters, the residence time is 0.75 hours, and the total residence time of the curing bath is 3.75 hours. After passing through the curing bath, the pitch continuous fibers prepared by spinning and curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com