Reinforcement layer and wearing layer one-step molding metal shielding mobile rubber jacketed flexible cable

A technology of forming metal and metal shielding, which is applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of reduced electrical insulation performance of cables, non-wearable cable sheaths, and broken conductors, so as to avoid viscosity reduction, The effect of avoiding stain residue and simplifying the processing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

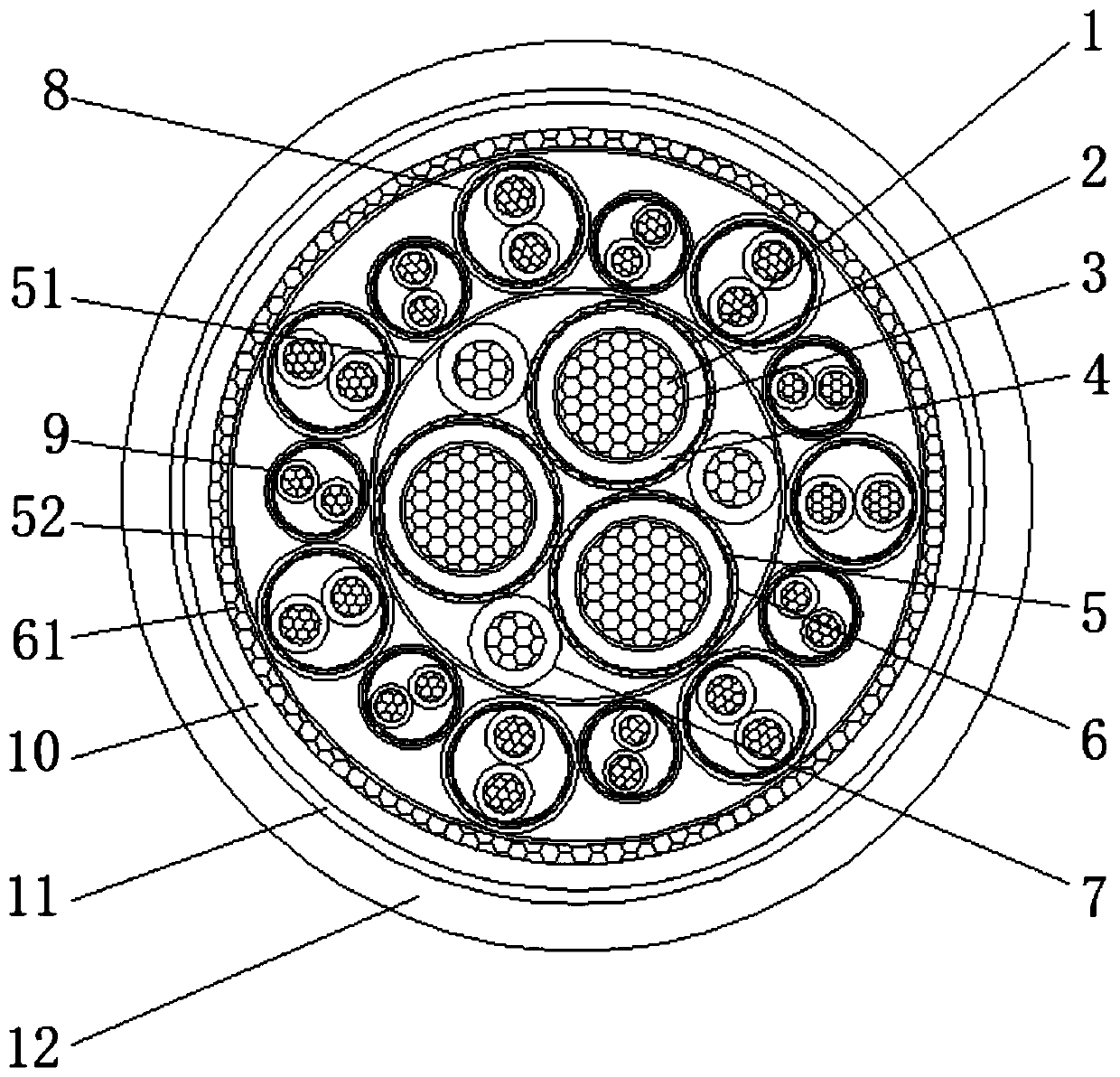

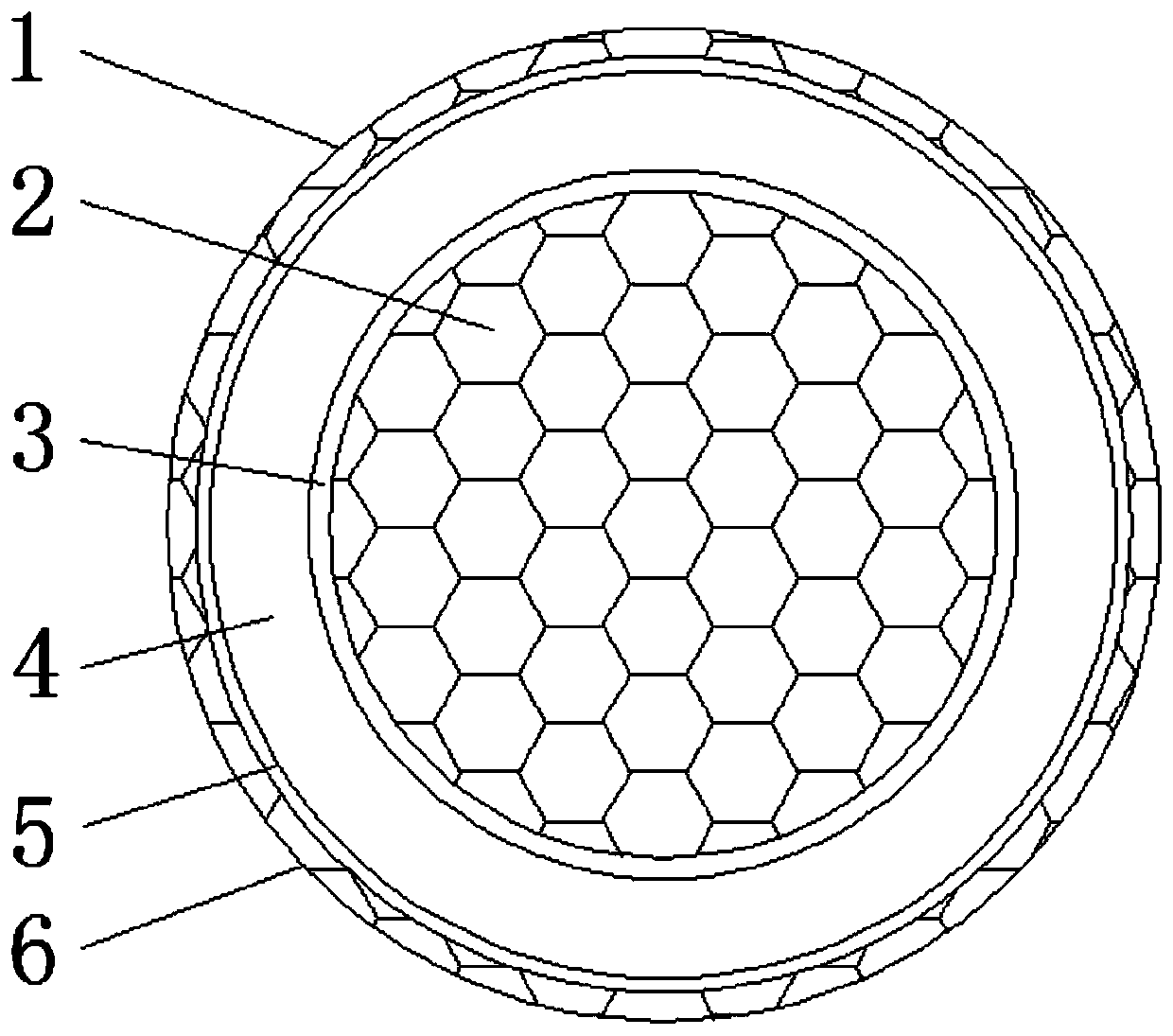

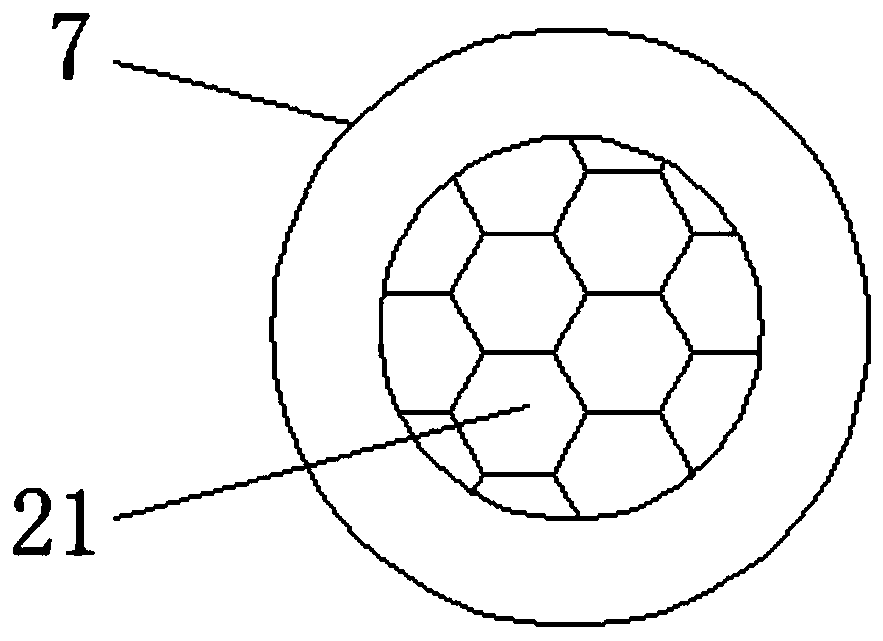

[0048] see Figure 1-6 , an embodiment provided by the present invention: a flexible cable with metal shielding mobile rubber sheath formed by a reinforced layer and a wear-resistant layer at one time, including a wear-resistant layer, a reinforced layer 11, a metal overall shielding layer 61, an outer cable core and an inner cable core ; The inner cable core includes 3 insulated power cores 1 and 3 ground cores twisted in the left direction, and the first insulation isolation resistance wrapped around the stranded structure formed by the insulated power core 1 and the ground core 7 Water-encapsulated tape layer 51; the outer cable core includes the inner cable core as the center, 7 groups of shielded control wire cores 8, 2 to 7 groups of instrument signal wire cores 9 twisted leftward outside the inner cable core, and the outer cable core is also It includes the second insulation isolation water-blocking tape layer 52 and the metal overall shielding layer 61 wrapped around t...

Embodiment 2

[0064] The difference from Embodiment 1 above is that in this example, the braid pitch ratio of the first metal shielding reinforcement layer 6 , the second metal shielding reinforcement layer 62 and the third metal shielding reinforcement layer 63 is three.

[0065] The insulating layer 4, the second insulating layer 41 and the third insulating layer 42 are all made up of the following raw materials in parts by weight:

[0066] 40 parts of methyl silicone rubber, 70 parts of EPDM rubber; 10 parts of ethylene-vinyl acetate copolymer; 5 parts of zinc oxide; 5 parts of DCBP; 6 parts of TAIC; 2 parts of RD; 10 parts of paraffin oil; 4 parts of paraffin; 70 parts of talcum powder; 15 parts of white carbon black; 6 parts of coupling agent.

[0067] In this embodiment, a method for manufacturing a metal-shielded mobile rubber-sheathed flexible cable with a reinforced layer and a wear-resistant layer at one time includes the following steps:

[0068] a. Pass the formed outer cable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com