Cleaning brush structure for washing machine

A technology for descaling brushes and washing machines, applied to other washing machines, brushes, brush bodies, etc., which can solve the problems of limited applicability, increased cost, and complicated components, and achieve the effects of maintaining effectiveness, avoiding stubborn dirt, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

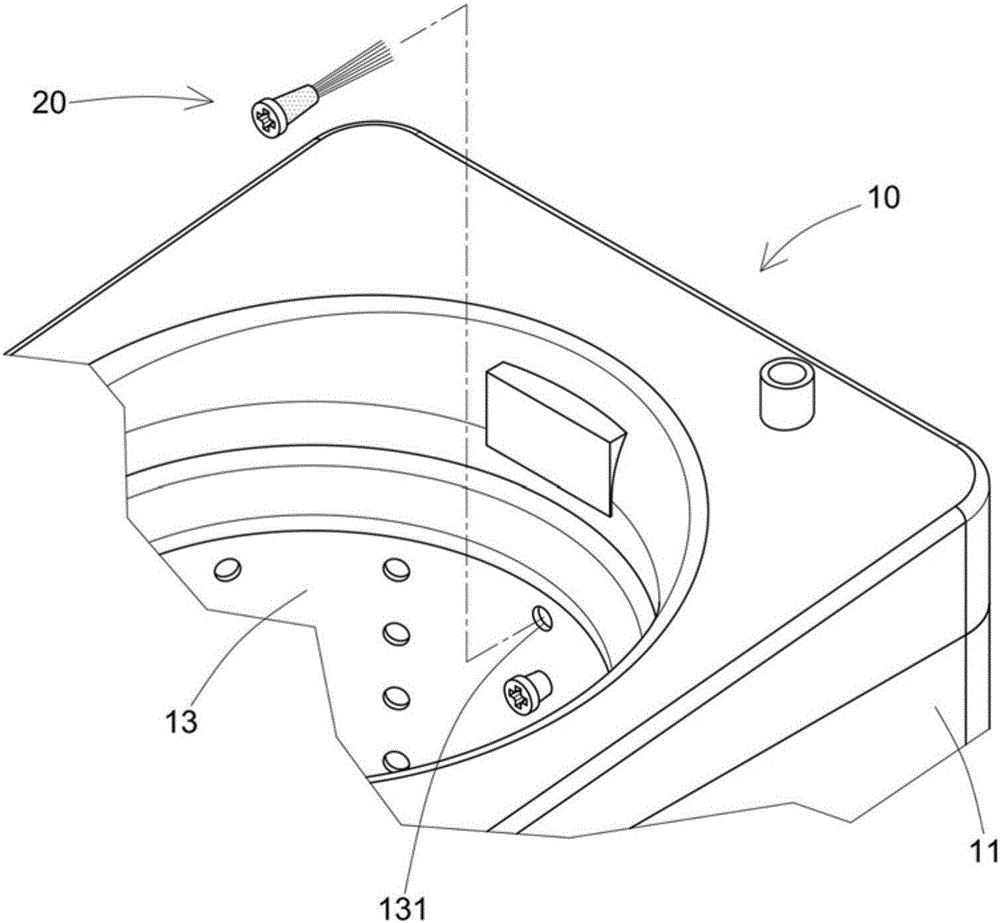

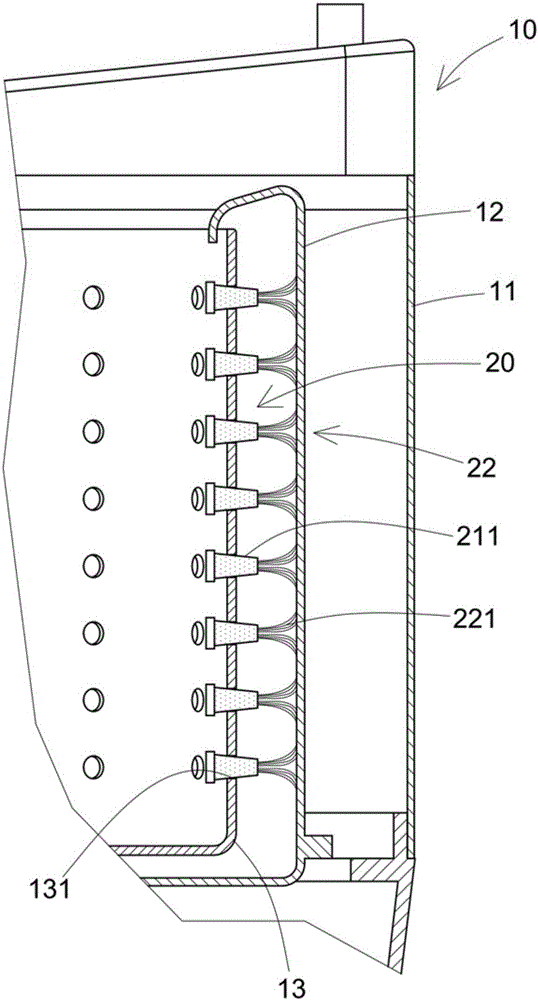

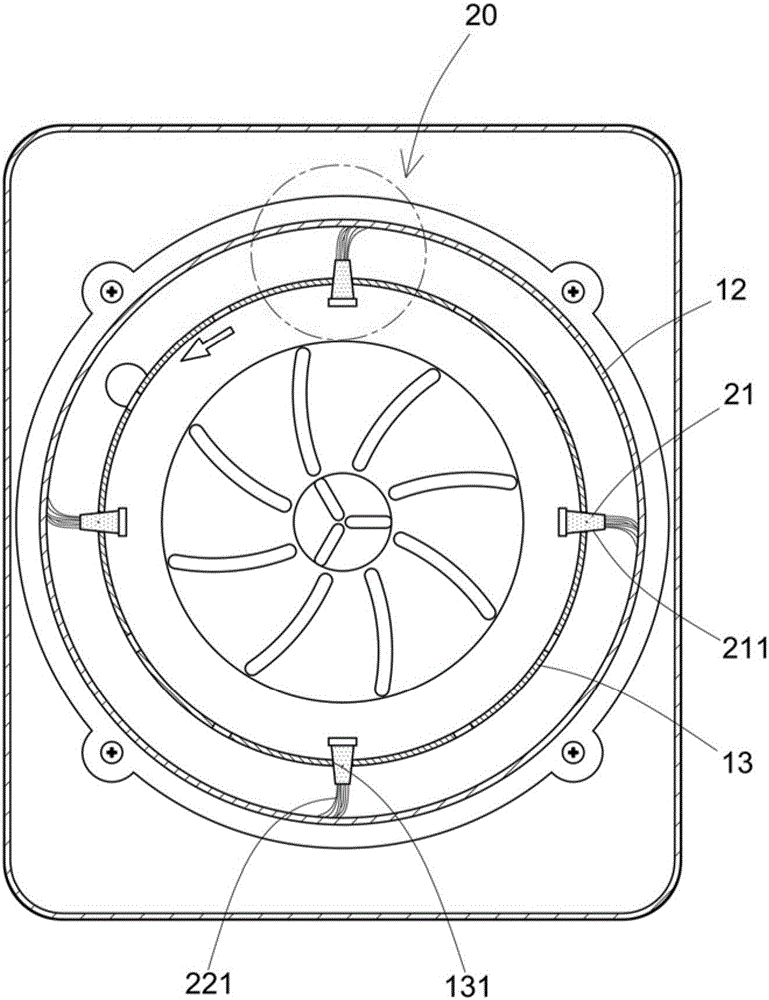

[0032] Such as Figure 1 to Figure 10 As shown, the present invention provides a descaling brush for a washing machine. The washing machine includes a body 11, an outer cylinder 12 is arranged inside the body 11, and an inner cylinder 13 with several perforations 131 is installed inside the outer cylinder 12 (such as figure 1 shown), through the action of the transmission mechanism of the washing machine 10, it can be linked to the rotation of the inner tube 13, and then perform the laundry action; each perforation 131 of the inner tube 13 is respectively provided with a descaling brush 20, the Descaling brush 20 is made up of fixing part 21 and bristle part 22, and the outside of described fixing part 21 is tapered surface 211, makes described fixing part 21 comprise small-diameter end 21A and large-diameter end 21B,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com