Preparation and application method of nanofiber sodium-storage positive material assembled by nanoparticles

A nanofiber and nanoparticle technology, applied in the field of nanofiber sodium storage cathode material preparation, can solve the problems of unsuitability for industrial production, complex synthesis conditions, poor air stability, etc., and achieves easy control of reaction conditions, simple preparation process, and cycle life. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Dissolve 4.4g of polyvinylpyrrolidone (PVP) in 30mL of deionized water, stir until completely dissolved, add 3mL of glacial acetic acid to adjust the pH of the solution to 4-5, and make solution A;

[0030] 2) 0.4462g sodium nitrate (NaNO 3 ) (5% excess), 0.727g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), 1.2255g manganese acetate (Mn(CH 3 COOH) 2 4H 2 O) add in solution A successively, form homogeneous solution B under continuous magnetic stirring;

[0031] 3) Transfer the above solution B into a syringe, with 12-15 μL min -1 The propulsion speed is injected into the receiving aluminum foil, the distance between the injector and the receiving aluminum foil is 15-20cm, and a high-voltage electrostatic field of 16-18kV is applied between the injector and the receiving aluminum foil, and the spinning time is 10-15h, and the collected electrospun Film thickness is 30-50μm;

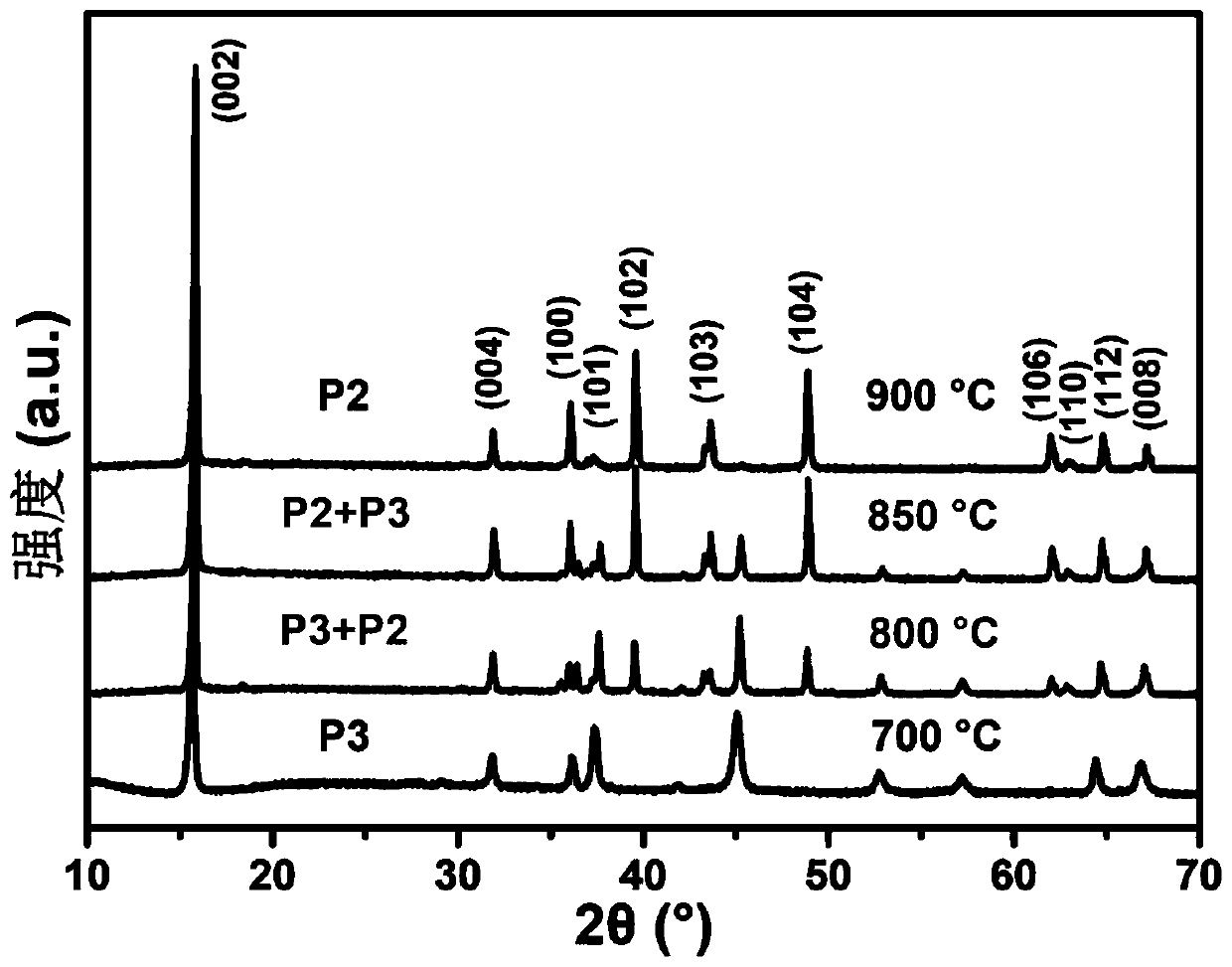

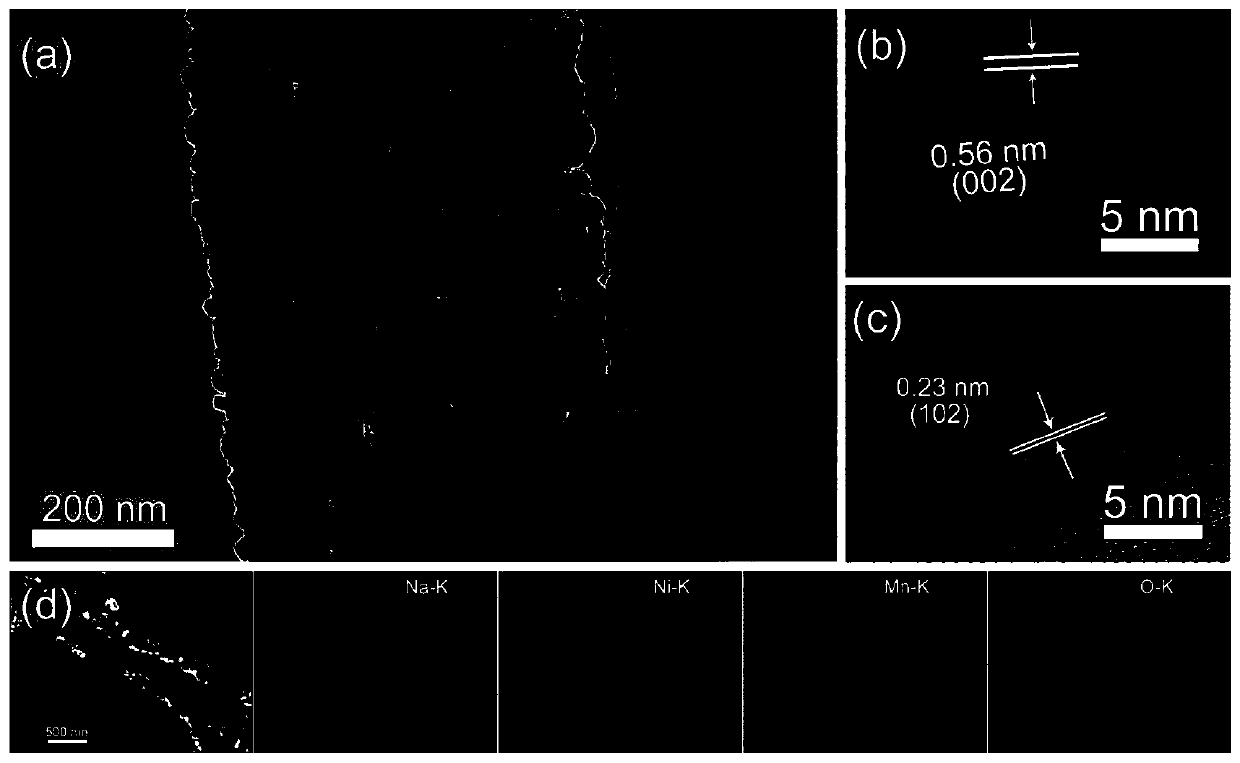

[0032] 4) Heat the electrospun film collected above in an air atmosphere to 500°C at a heating...

Embodiment 2

[0038] 1) Dissolve 4.4g of polyvinylpyrrolidone (PVP) in 30mL of deionized water, stir until completely dissolved, and make solution A;

[0039] 2) 0.4462g sodium nitrate (NaNO 3 ) (5% excess), 0.727g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O), 1.250g manganese nitrate (Mn(NO 3 ) 2 4H 2 O) add in solution A successively, form homogeneous solution B under continuous magnetic stirring;

[0040] 3) Transfer the above solution B into a syringe, with 12-15 μL min -1 The propulsion speed is injected into the receiving aluminum foil, the distance between the injector and the receiving aluminum foil is 15-20cm, and a high-voltage electrostatic field of 16-18kV is applied between the injector and the receiving aluminum foil, and the spinning time is 10-15h, and the collected electrospun Film thickness is 30-50μm;

[0041] 4) Heat the electrospun film collected above in an air atmosphere to 500°C at a heating rate of 2°C / min and keep it warm for 2 hours to decompose PVP and form a por...

Embodiment 3

[0045] 1) Dissolve 4.4g of polyvinylpyrrolidone (PVP) in 30mL of deionized water, stir until completely dissolved, add 3mL of glacial acetic acid to adjust the pH of the solution to 4-5, and make solution A;

[0046] 2) 0.7144g sodium acetate (CH 3 COONa·3H 2 O) (5% excess), 0.6218g nickel acetate (Ni(CH 3 COOH) 2 4H 2 O), 1.2255g manganese acetate (Mn(CH 3 COOH) 2 4H 2 O) add in solution A successively, form homogeneous solution B under continuous magnetic stirring;

[0047] 3) Transfer the above solution B into a syringe, with 12-15 μL min -1 The propulsion speed is injected into the receiving aluminum foil, the distance between the injector and the receiving aluminum foil is 15-20cm, and a high-voltage electrostatic field of 16-18kV is applied between the injector and the receiving aluminum foil, and the spinning time is 10-15h, and the collected electrospun Film thickness is 30-50μm;

[0048] 4) Heat the electrospun film collected above in an air atmosphere to 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com