Sulfur vacancy nitrogen-doped carbon-coated nickel sulfide composite electrode material and preparation method thereof

A nitrogen-doped carbon and composite electrode technology, which is applied in the preparation/purification of nickel sulfide, carbon, negative electrodes, etc., can solve the problems of complex process, low production efficiency, and difficulty in large-scale industrial production, so as to improve interstitial diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the sulfur-vacancy nitrogen-doped carbon-coated nickel sulfide composite electrode material of the present invention comprises the following steps in sequence:

[0033] S1: Dissolve 5mmol of nickel acetate in 20mL of deionized water to obtain a nickel acetate solution; dissolve 5mmol of hexamethylenetetramine in 20mL of ethanol to obtain a hexamethylenetetramine solution;

[0034] S2: Mix the nickel acetate solution and the hexamethylenetetramine solution uniformly by dropping, and then stand and grow at 100° C. for 20 hours to obtain the primary product containing the nickel-based metal organic framework template;

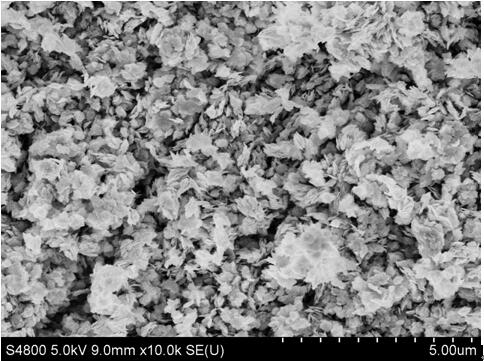

[0035] S3: centrifuge the primary product containing the nickel-based metal organic framework template, wash with deionized water and absolute ethanol three times respectively, to obtain a clean nickel-based metal organic framework template; figure 1 As shown, the nickel-based metal-organic framework template prepared in Example 1 ...

Embodiment 2

[0039] The preparation method of the sulfur-vacancy nitrogen-doped carbon-coated nickel sulfide composite electrode material of the present invention comprises the following steps in sequence:

[0040] S1: Dissolve 10mmol of nickel nitrate in 40mL of deionized water to obtain a nickel acetate solution; dissolve 30mmol of hexamethylenetetramine in 40mL of methanol to obtain a hexamethylenetetramine solution;

[0041] S2: The nickel nitrate solution and the hexamethylenetetramine solution were mixed uniformly by dropping, and then left to grow at 80° C. for 24 hours to obtain the primary product containing the nickel-based metal organic framework template;

[0042] S3: centrifuge the primary product containing the nickel-based metal-organic framework template, wash it with deionized water and absolute ethanol three times respectively, and obtain a clean nickel-based metal-organic framework template;

[0043] S4: After mixing the clean nickel-based metal-organic framework template ...

Embodiment 3

[0046] The preparation method of the sulfur-vacancy nitrogen-doped carbon-coated nickel sulfide composite electrode material of the present invention comprises the following steps in sequence:

[0047] S1: Dissolve 10mmol of nickel chloride in 50mL of deionized water to obtain a nickel acetate solution; dissolve 70mmol of hexamethylenetetramine in 100mL of acetone to obtain a hexamethylenetetramine solution;

[0048] S2: Mix the nickel chloride solution and the hexamethylenetetramine solution uniformly by dropping, and then stand and grow at 150° C. for 15 hours to obtain the primary product containing the nickel-based metal-organic framework template;

[0049] S3: centrifuge the primary product containing the nickel-based metal-organic framework template, wash it with deionized water and absolute ethanol three times respectively, and obtain a clean nickel-based metal-organic framework template;

[0050] S4: After mixing the clean nickel-based metal-organic framework template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com