A cathode material for sodium ion battery and a preparation method thereof

A technology for sodium ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that the coating agent does not have the reactivity of the positive electrode material, and cannot enhance the conductivity of the composite material, so as to improve the sodium storage capacity and Cycling stability, the effect of improving the cycling stability, and increasing the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a sodium ion battery cathode material. The iron salt is dissolved in a fluorine-containing ionic liquid, and the resulting mixed solution is stirred with a carbon source and a Prussian blue-type sodium ion cathode material to perform a solvothermal reaction to obtain iron-based fluorine Prussian blue-based composite sodium ion battery cathode material is modified by in-situ coating of compound and carbon.

[0029] Preferably, in the preparation method, the mass ratio of the Prussian blue-based sodium ion cathode material, the iron salt and the carbon source is 1:(0.01-0.5):(0.01-0.5); further preferably, the Prussian blue-based sodium ion cathode material, The mass ratio of the iron salt and the carbon source is 1: (0.01-0.2): (0.1-0.5).

[0030] Preferably, in the preparation method, the iron salt is a trivalent iron salt; further preferably, the iron salt is ferric nitrate; still further, the iron salt is Fe(NO 3 ) 3 ·9H 2 O.

[0031] Preferably, in t...

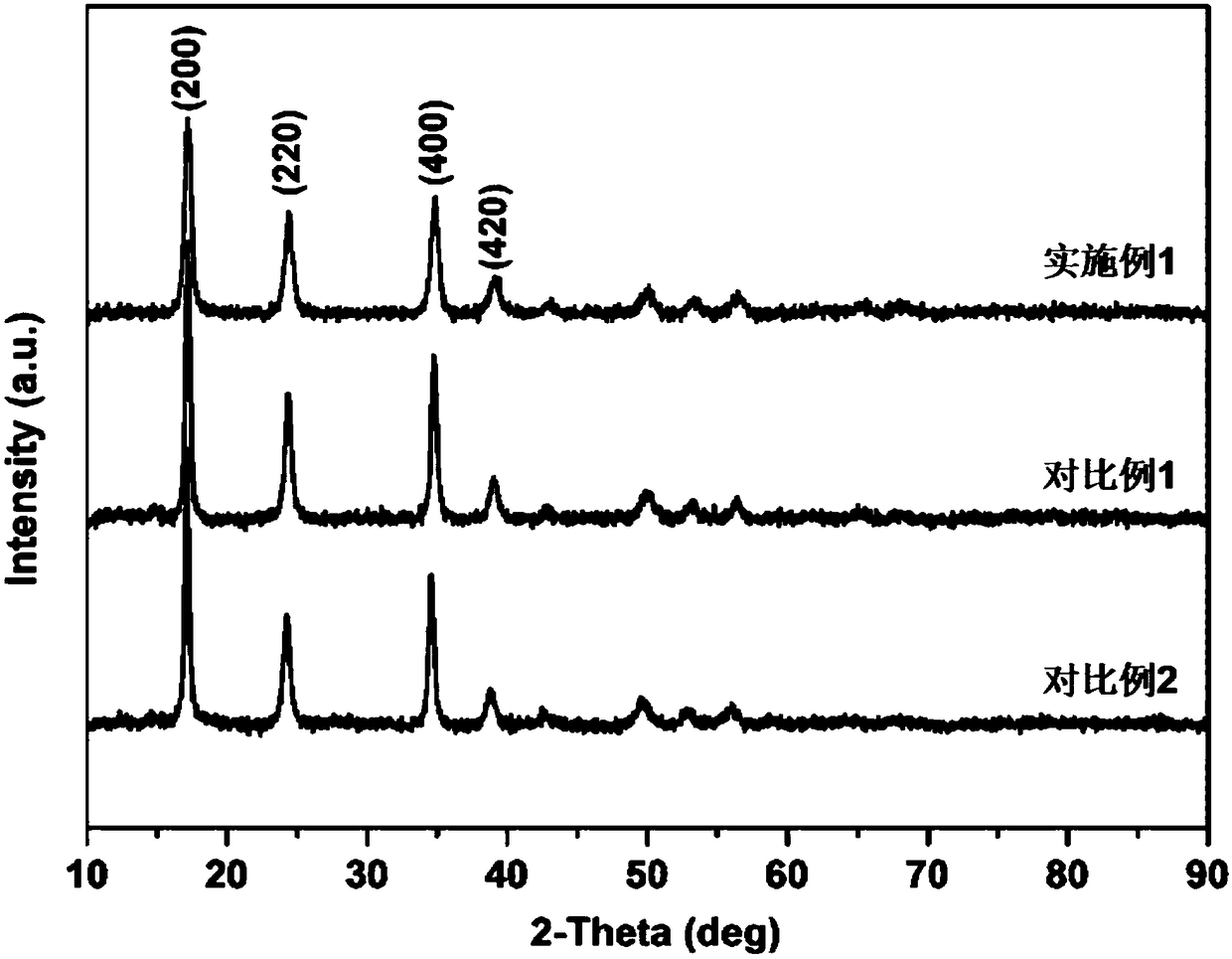

Embodiment 1

[0043] Na 4 Fe(CN) 6 ·10H 2 O is the raw material, and FeCl 2 ·4H 2 O and complexing agent sodium citrate are dissolved in deionized water at room temperature and reacted. After washing and drying, Na is synthesized 1.7 FeFe(CN) 6 Prussian blue-based sodium ion cathode material.

[0044] Take 0.5gFe(NO 3 )·9H 2 O dissolved in 15mL ionic liquid [BMIM][BF 4 ], then add 0.5g Super-P and 2gNa to the mixed yellow solution 1.7 FeFe(CN) 6 The mixed powder, stir for 2min, put it in 100℃ for solvothermal 12h, after natural cooling, wash with absolute ethanol and acetone, and dry to obtain FeF 3 ·0.5H 2 O and Super-P in situ coated Na 1.7 FeFe(CN) 6 Composite cathode material for sodium ion battery.

Embodiment 2

[0046] Na 4 Fe(CN) 6 ·10H 2 O is the raw material, and FeCl 3 ·6H 2 O reacts under hydrothermal conditions and is washed and dried to synthesize NaFeFe(CN) 6 Prussian blue-based sodium ion cathode material.

[0047] Take 0.6gFe(NO 3 )·9H 2 O dissolved in 20mL ionic liquid [BMIM][BF 4 ], then add 0.4g Ketjen Black and 2gNaFeFe(CN) to the mixed yellow solution 6 The mixed powder, stirred for 1 min, put into 60 ℃ for solvent heating for 6 hours, after natural cooling, washed with absolute ethanol and acetone, dried to obtain FeF 3 ·0.33H 2 NaFeFe(CN) coated in situ with O and Ketjen Black 6 Composite cathode material for sodium ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com