A co-doped flexible sodium ion battery cathode material and a preparation method thereof

A technology for sodium ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high preparation cost, failure to use flexible electrodes, complicated preparation methods, etc., and achieve high capacity and excellent market application. Value, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of this co-doped flexible sodium ion battery cathode material comprises the following steps:

[0034] 1) mixing the nickel salt solution and the transition metal salt solution to obtain a mixed salt solution;

[0035] 2) Mix the mixed salt solution with Na 4 Fe(CN) 6 Mixing of solutions, avoiding light reaction, aging;

[0036] 3) Extract the composite flexible substrate obtained by the reaction, wash, dry, and press to obtain a co-doped flexible sodium-ion battery positive electrode material, whose chemical formula is Na 2 Ni m m n Fe(CN) 6 , the value ranges of m and n are as mentioned above.

[0037] Preferably, in step 1) of the preparation method, the concentration of the nickel salt solution or the transition metal salt solution is 0.005mol / L-0.2mol / L.

[0038] Preferably, in step 1) of the preparation method, the amount of nickel salt and transition metal salt is 0≤Ni / M≤10 according to the stoichiometric ratio of Ni and transition me...

Embodiment 1

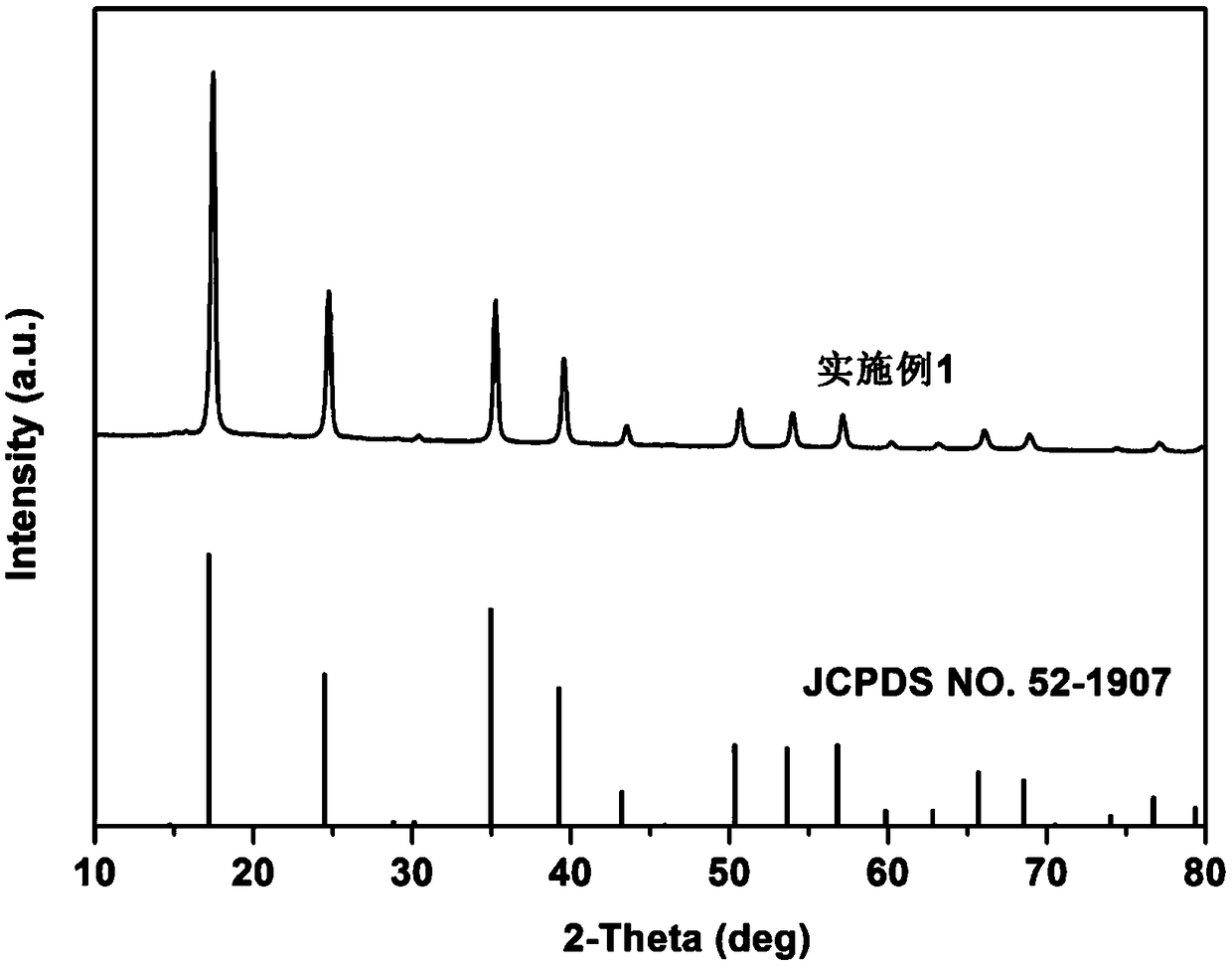

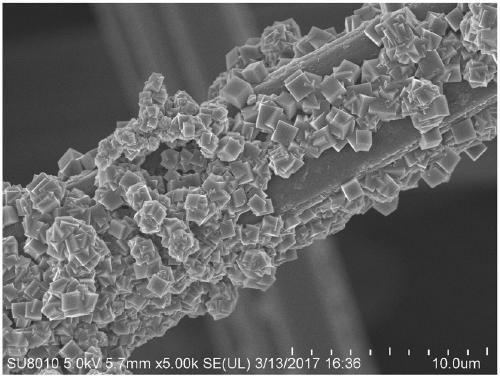

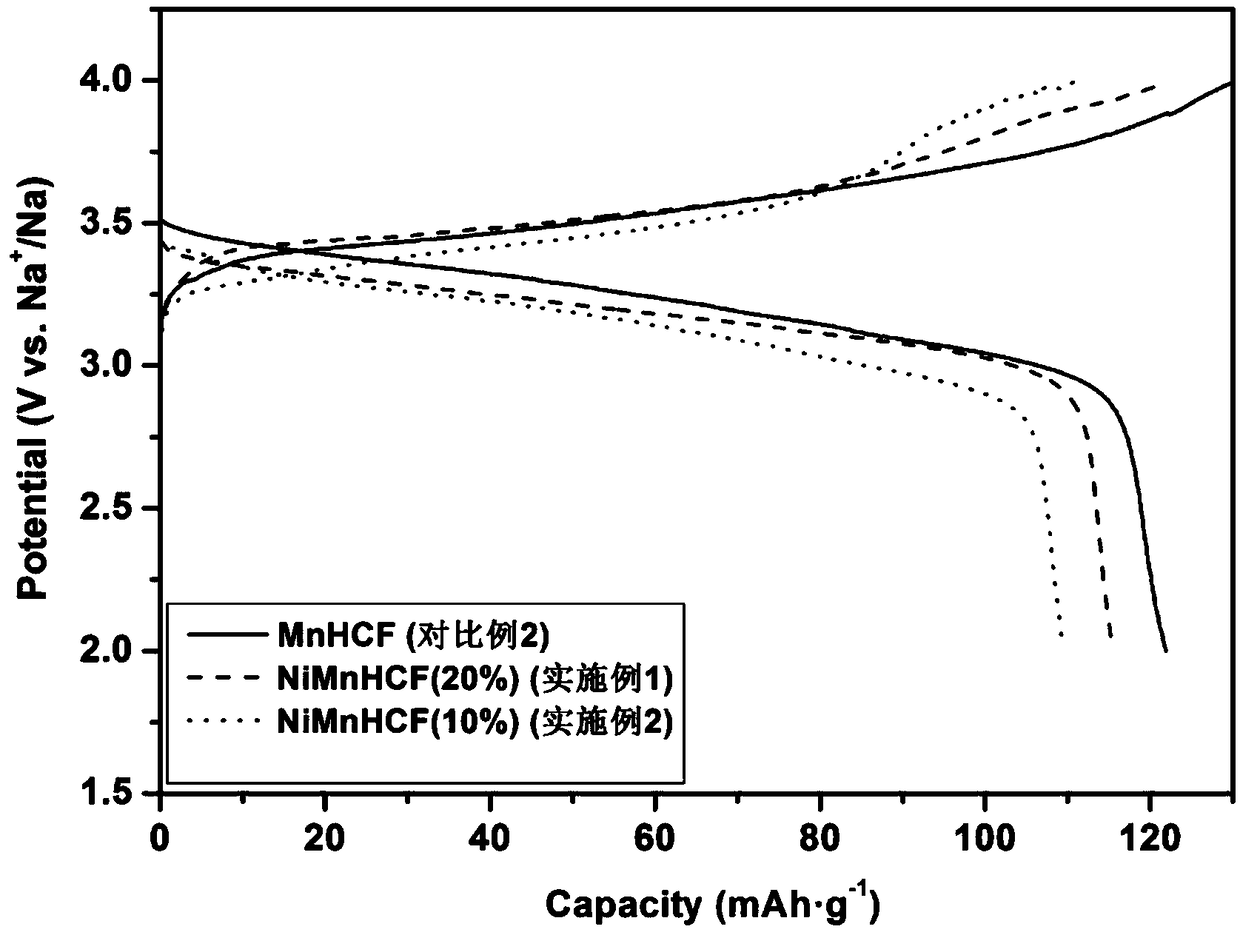

[0054] Take 0.129g NiCl according to the ratio of Ni to Mn stoichiometric ratio 1:4 2 and 0.503g MnCl 2 Dissolve in 50mL deionized water respectively, and then mix the two solutions evenly in a 350mL beaker and record it as mixed solution A; another 2.42g Na 4 Fe(CN) 6 10H 2 O was dissolved in 100mL deionized water, recorded as solution B, and a square conductive carbon cloth with a mass of 0.182g and a side length of 40mm was added to solution B; then the mixed solution A was slowly added dropwise to the solution in a dark environment In B, use 100W low-power ultrasound for 2 hours in this process, and after aging for 20 hours, separate the composite flexible substrate and sediment powder at this time, wash with absolute ethanol and deionized water alternately for 3 times, and then put it in a vacuum at 60 °C After 24 hours in the drying oven, the composite flexible carbon cloth was rolled to obtain the Prussian blue analogue Na 2 Ni 0.2 mn 0.8 Fe(CN) 6 Na-ion battery ...

Embodiment 2

[0056] Take 0.065g NiCl according to the ratio of Ni to Mn stoichiometric ratio 1:9 2 and 0.566g MnCl 2 Dissolve in 50mL deionized water respectively, and then mix the two solutions evenly in a 350mL beaker and record it as mixed solution A; another 2.42g Na 4 Fe(CN) 6 10H 2 O was dissolved in 100mL deionized water, recorded as solution B, and a square conductive carbon cloth with a mass of 0.182g and a side length of 40mm was added to solution B; then the mixed solution A was slowly added dropwise to the solution in a dark environment In B, use 100W low-power ultrasound for 6 hours in this process, and after aging for 18 hours, take out the composite flexible substrate and sediment powder at this time, alternately wash 3 times with absolute ethanol and deionized water, and then put it in 60 ° C for vacuum drying After 24 hours in the box, the composite flexible carbon cloth was rolled to obtain the Prussian blue analog Na 2 Ni 0.1 mn 0.9 Fe(CN) 6 Na-ion battery flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com