A kind of nitrogen and phosphorus co-doped porous biomass carbon material and its preparation method and application in supercapacitor

A technology of biomass carbon and co-doping, which is applied in the direction of carbon preparation/purification, hybrid capacitor electrodes, etc., and can solve problems such as complicated steps, complicated process, and destruction of pore distribution advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the nitrogen and phosphorus co-doped porous biomass carbon material of the present embodiment:

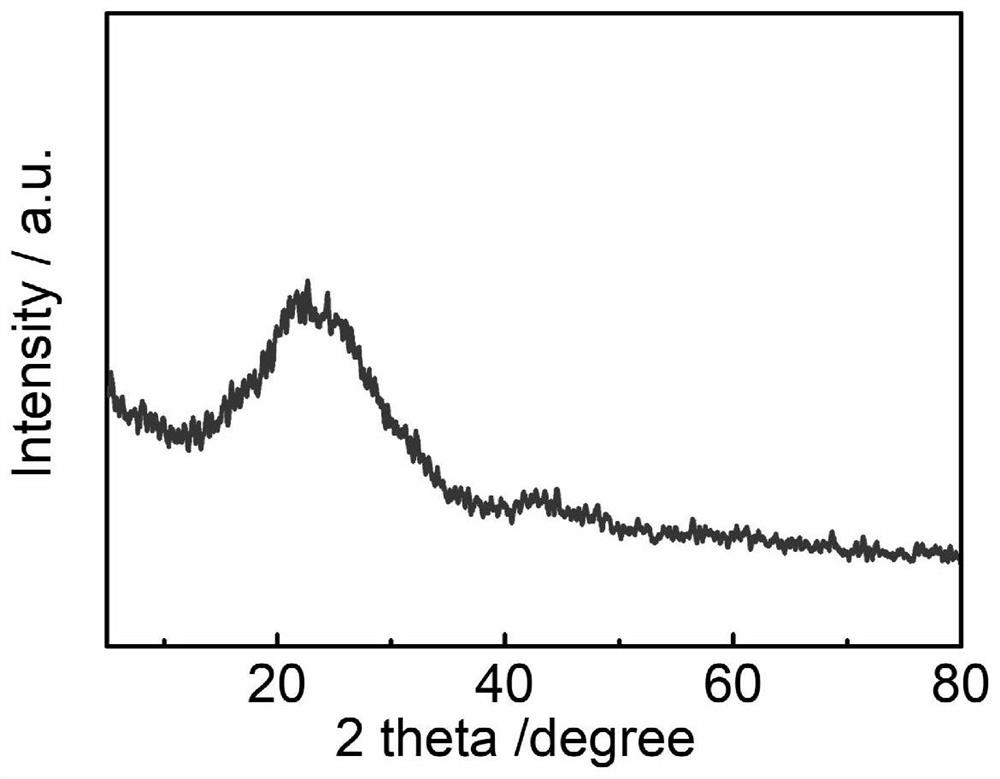

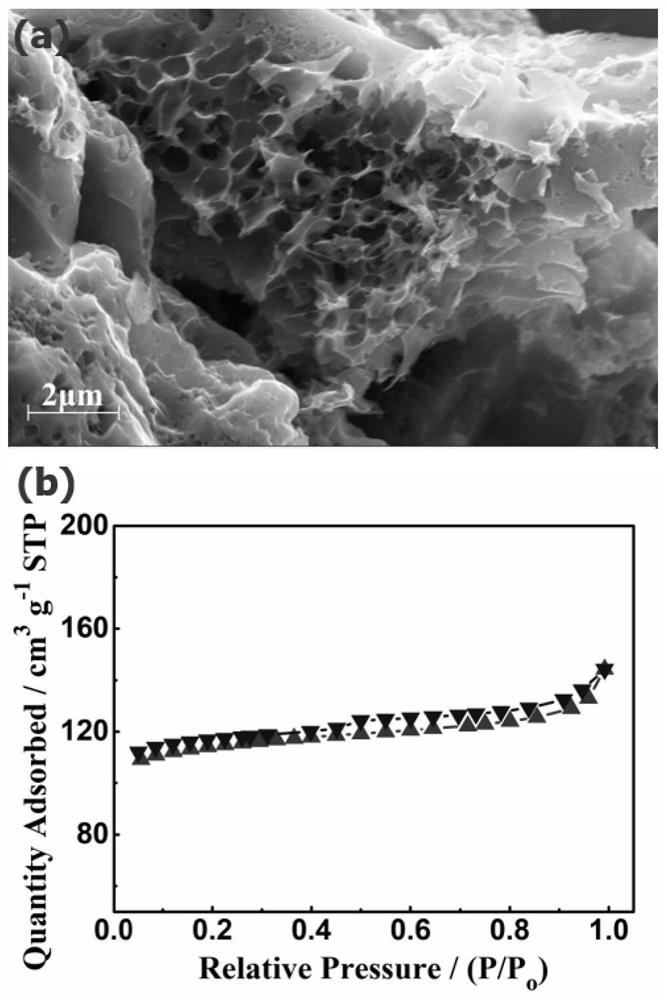

[0030] Mix and grind 2 g of air-dried and ground oyster mushroom powder with 6 g of ammonium dihydrogen phosphate, then transfer it to a small porcelain boat, put it into a tube furnace, and raise the temperature to 500 °C at 5 °C / min under the protection of a nitrogen atmosphere. 2h, naturally cooled to room temperature, then soaked and washed the material with 0.2mol / L hydrochloric acid solution, then washed with deionized water until neutral (pH=7), and finally dried at 80°C for 12h to prepare nitrogen and phosphorus co-doped porous biomass carbon material with a yield of about 40.3%. From figure 1 It can be seen that the obtained carbon material has an amorphous structure and no other impurities. figure 2 It can be seen from the SEM image (a) that it is a multi-level pore structure, which is determined by figure 2 (b) The specific surface a...

Embodiment 2

[0033] The preparation method of the nitrogen and phosphorus co-doped porous biomass carbon material of the present embodiment:

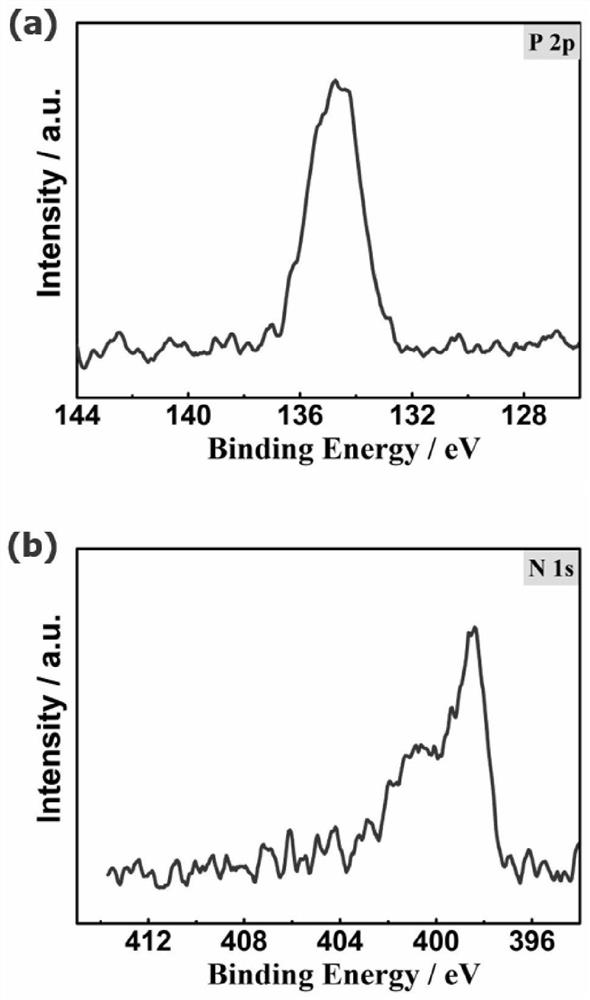

[0034]Mix and grind 1 g of air-dried and ground oyster mushroom powder with 2 g of ammonium dihydrogen phosphate, then transfer it to a small porcelain boat, put it into a tube furnace, and raise the temperature to 500 °C at 3 °C / min under the protection of nitrogen atmosphere. 3h, naturally cooled to room temperature, then soaked and washed the material with 0.2mol / L hydrochloric acid solution, then washed with deionized water until neutral (pH=7), and finally dried at 80°C for 12h to prepare nitrogen and phosphorus co-doped porous biomass carbon material with a yield of 44.2wt%. Depend on image 3 It can be explained that N and P are successfully doped into the carbon material, and the N content is 6.6wt% and the P content is 9.2wt% according to XPS analysis. In the same way, we changed the quality of ammonium dihydrogen phosphate, respectively ...

Embodiment 3

[0036] The preparation method of the porous biomass carbon material co-doped with nitrogen and phosphorus in this embodiment comprises the following steps:

[0037] Mix and grind 1 g of air-dried and ground Pleurotus ostreatus powder with 3 g of ammonium phosphate, then transfer it to a small porcelain boat, put it into a tube furnace, and raise the temperature to 650 °C at 3 °C / min under the protection of nitrogen atmosphere, and keep it for 3 hours. Naturally cool to room temperature, soak and wash the material with 0.2mol / L hydrochloric acid solution, wash with deionized water until neutral (pH=7), and finally dry at 80°C for 12 hours to prepare nitrogen-phosphorus co-doped porous Biomass carbon materials.

[0038] Further, the above obtained samples were subjected to electrochemical rate performance test. For comparison, the obtained samples were roasted without adding ammonium phosphate under the same conditions to obtain pure biomass carbon materials. Test method: Mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com