Nitrogen-sulfur-doped nano-porous carbon material taking sodium alginate as raw material and preparation method of nitrogen-sulfur-doped nano-porous carbon material

A technology of nanoporous carbon and sodium alginate, which is applied in the direction of nanocarbon, nanotechnology, carbon compounds, etc., and can solve problems such as hindering practical application, poor rate performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

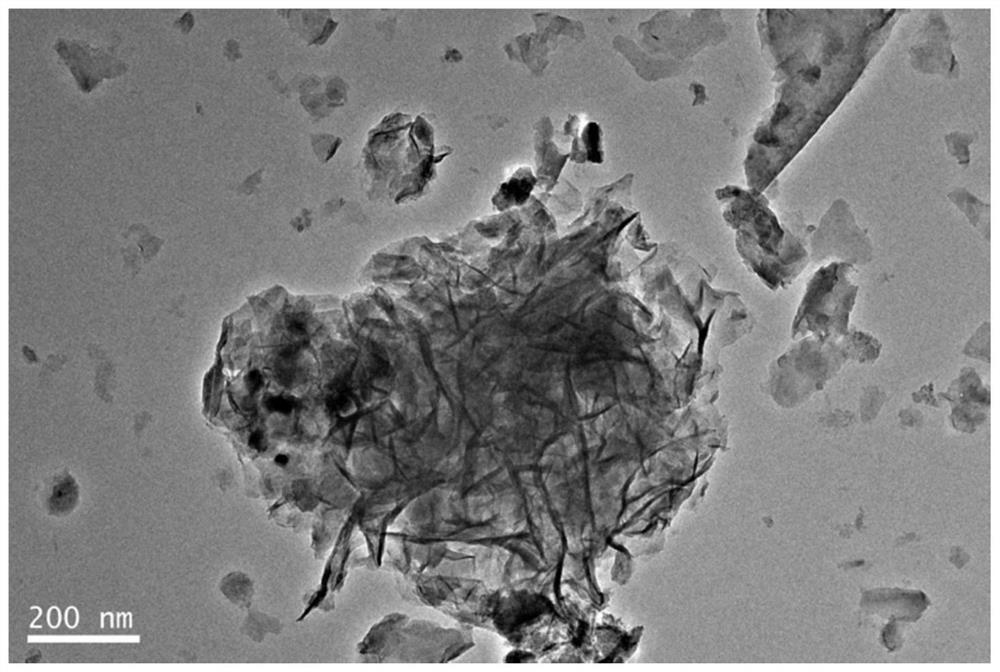

[0028] A preparation method of nitrogen-sulfur-doped nanoporous carbon material using sodium alginate as raw material, comprising the following steps:

[0029] 1) Slowly dissolve 2g of sodium alginate powder in 60ml of deionized aqueous solution containing 0.5g of thiourea, continue stirring and heating to form a solution;

[0030] 2) Add 3.91g of calcium acetate to 20ml of deionized water, slowly drop into sodium alginate thiourea solution to form a gel, and keep stirring for 1h;

[0031] 3) The gel in step 2) is freeze-dried and pulverized, and pre-frozen with liquid nitrogen before freeze-drying;

[0032] 4) Activate the sample in step 3) by high-temperature carbonization, and then wash and dry it with hydrochloric acid and deionized water to obtain a nitrogen-sulfur-doped nanoporous carbon material prepared by a freeze-drying assisted carbonization template method, wherein the carbonization temperature is 600 ° C, The drying time is 2 hours, the drying temperature is 60° ...

Embodiment 2

[0038] A preparation method of nitrogen-sulfur-doped nanoporous carbon material using sodium alginate as raw material, comprising the following steps:

[0039] 1) Slowly dissolve 2g of sodium alginate powder in 60ml of deionized aqueous solution containing 0.6g of thiourea, continue stirring and heating to form a solution;

[0040] 2) Add 3.91g of calcium acetate to 20ml of deionized water, slowly drop into sodium alginate thiourea solution to form a gel, and keep stirring for 1 hour;

[0041] 3) The gel in step 2) is freeze-dried and pulverized, and pre-frozen with liquid nitrogen before freeze-drying;

[0042] 4) Activate the sample in step 3) by high-temperature carbonization, and then wash and dry it with hydrochloric acid and deionized water to obtain a nitrogen-sulfur-doped nanoporous carbon material prepared by a freeze-drying assisted carbonization template method, wherein the carbonization temperature is 600 ° C, The drying time is 5 hours, the drying temperature is ...

Embodiment 3

[0045] A preparation method of nitrogen-sulfur-doped nanoporous carbon material using sodium alginate as raw material, comprising the following steps:

[0046] 1) Slowly dissolve 2g of sodium alginate powder in 60ml of deionized aqueous solution containing 0.6g of thiourea, continue stirring and heating to form a solution;

[0047] 2) Add 3.91g of calcium acetate to 20ml of deionized water, slowly drop into sodium alginate thiourea solution to form a gel, and keep stirring for 1 hour;

[0048] 3) The gel in step 2) is freeze-dried and pulverized, and pre-frozen with liquid nitrogen before freeze-drying;

[0049] 4) Activate the sample in step 3) by high-temperature carbonization, and then wash and dry it with hydrochloric acid and deionized water to obtain a nitrogen-sulfur-doped nanoporous carbon material prepared by a freeze-drying assisted carbonization template method, wherein the carbonization temperature is 700 ° C, The drying time is 3 hours, the drying temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com