Preparation method and application of conducting polymer-based nanometer carbon fibers

A technology of conductive polymers and nano-carbon fibers, which can be used in the fields of fiber chemical characteristics, circuits, capacitors, etc., and can solve problems such as high cost, unfavorable, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Pre-oxidize 1 g of conductive polyaniline nanofibers in an air atmosphere at 200°C for 4 hours to obtain a pre-oxidized product; then put the pre-oxidized product into a high-temperature carbonization furnace and heat it under a nitrogen atmosphere with a heating rate of 1°C. min -1 , from room temperature to 600 ° C for 2 hours, that is, conductive polymer-based carbon nanofibers.

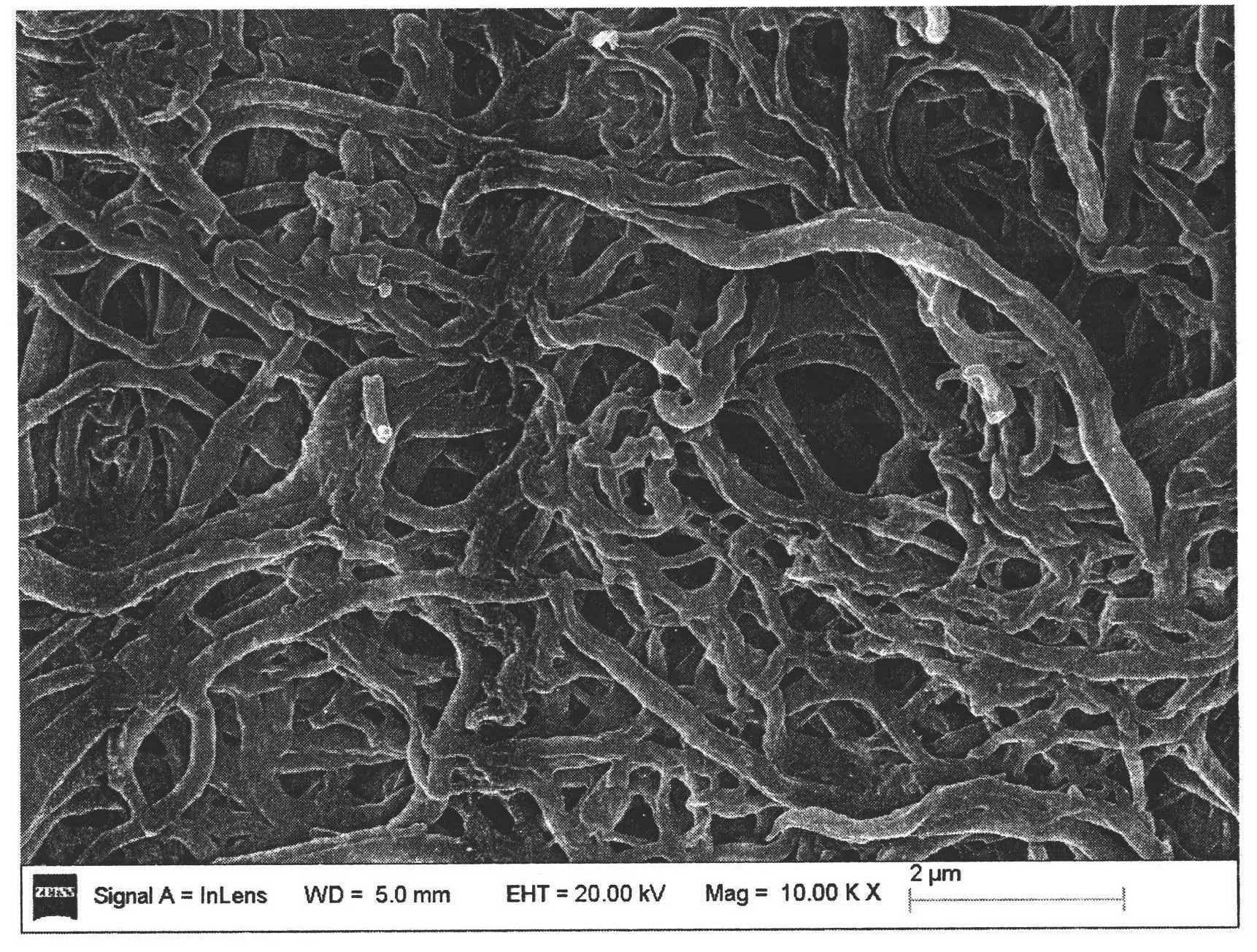

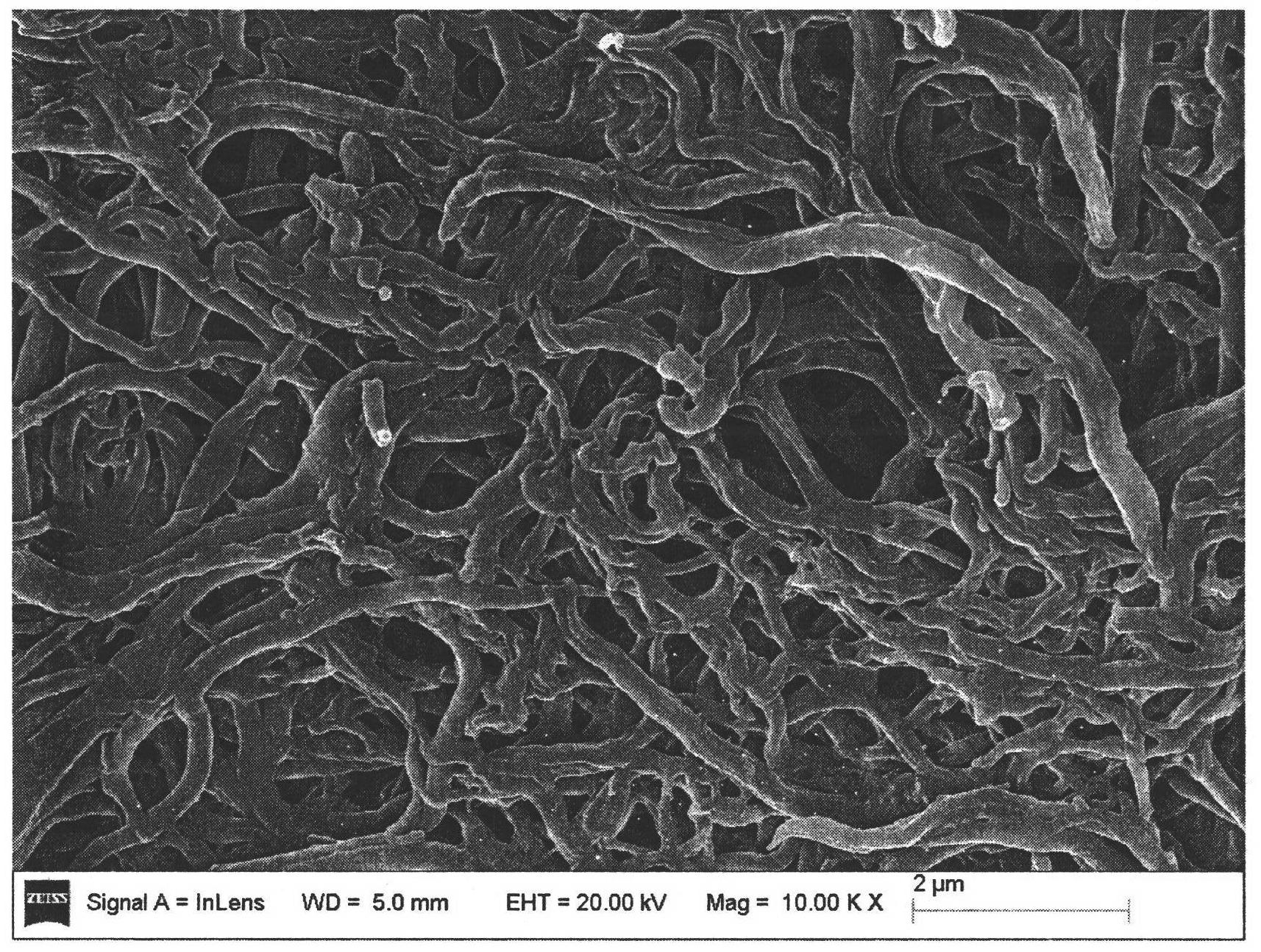

[0017] as attached figure 1 The morphology of polyaniline-based carbon fibers shown by scanning electron microscopy (SEM) remained intact.

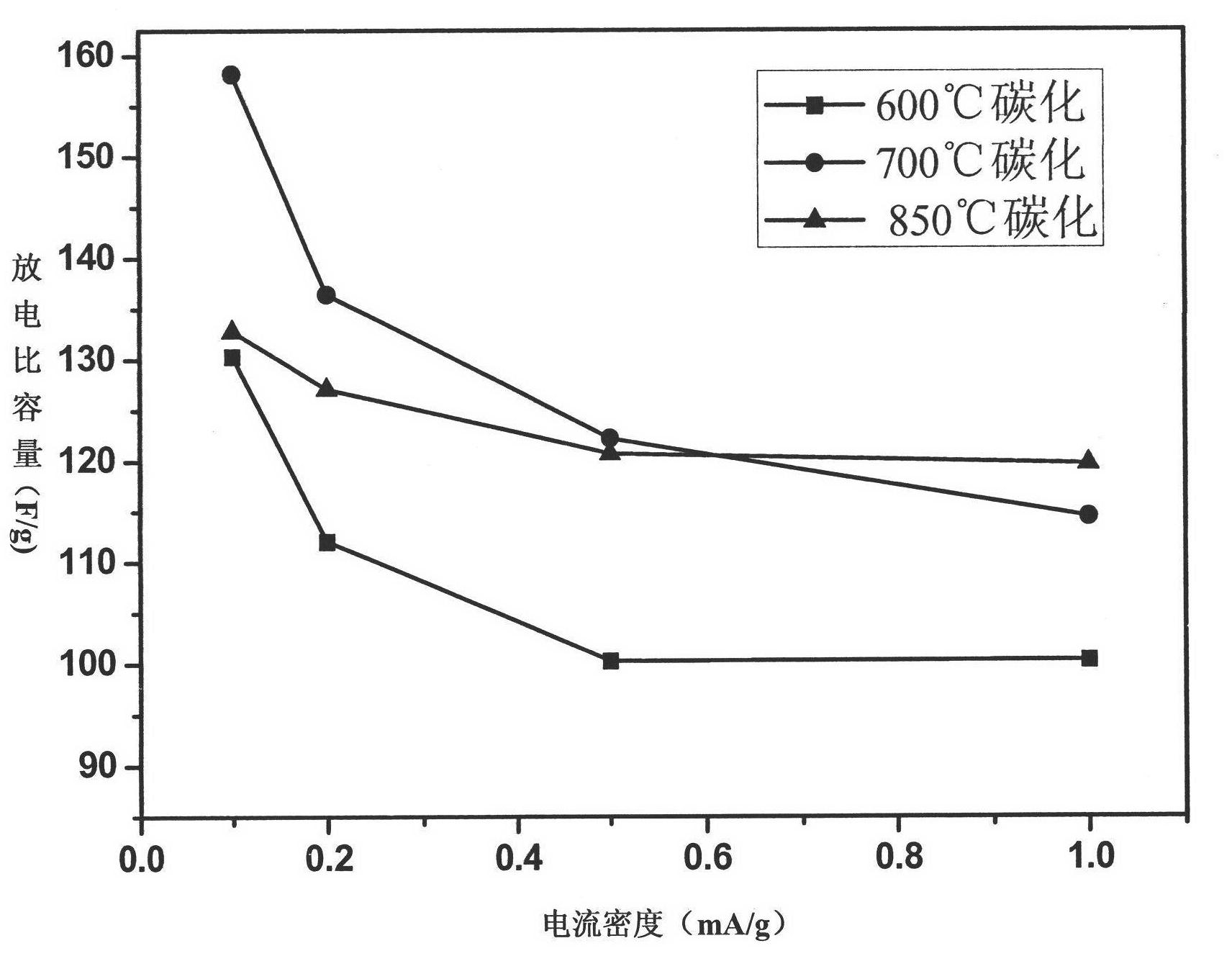

[0018] as attached figure 2 The results of electrochemical performance test show that the electrode material is at 0.1A·g -1 The discharge specific capacity under the current density can reach 130F·g -1 ; at 1A g -1 After 100 cycles at current density, the discharge specific capacity can maintain 110F·g -1 .

Embodiment 2

[0020] Pre-oxidize 1 g of conductive polypyrrole nanofibers in a carbon dioxide atmosphere at 300 °C for 3 h to obtain a pre-oxidized product; then put the pre-oxidized product into a high-temperature carbonization furnace and heat it under a nitrogen atmosphere with a heating rate of 1 °C. min -1 , from room temperature to 700 ° C for 1 hour, that is, conductive polymer-based carbon nanofibers.

[0021] as attached figure 2 The results of electrochemical performance test show that the electrode material is at 0.1A·g -1 The discharge specific capacity under the current density can reach 158F·g -1 ;1A·g -1 After 100 cycles at current density, the discharge specific capacity can maintain 110F·g -1 .

Embodiment 3

[0023] Pre-oxidize 1 g of conductive polythiophene nanofibers in a carbon dioxide atmosphere at 400 °C for 2 h to obtain a pre-oxidized product; then put the pre-oxidized product into a high-temperature carbonization furnace and heat it under a nitrogen atmosphere with a heating rate of 1 °C. min -1 , from room temperature to 850 ° C for 1 hour, that is, conductive polymer-based carbon nanofibers.

[0024] as attached figure 2 The results of electrochemical performance test show that the electrode material is at 0.1A·g -1 The discharge specific capacity under the current density can reach 132F·g -1 ;1A·g -1 After 100 cycles at current density, the discharge specific capacity can maintain 123F·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com