Process for extracting gold from gold ore containing copper by using ammonia, cyanide and carbon

A technology of carbon leaching and gold mining, which is applied in the direction of photographic process, photographic auxiliary process, and improvement of process efficiency. It can solve the problems of process adverse effects on process cost, increase in difficulty of gold extraction process, high investment and operating costs, and achieve environmental protection benefits. Obvious, low production cost, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

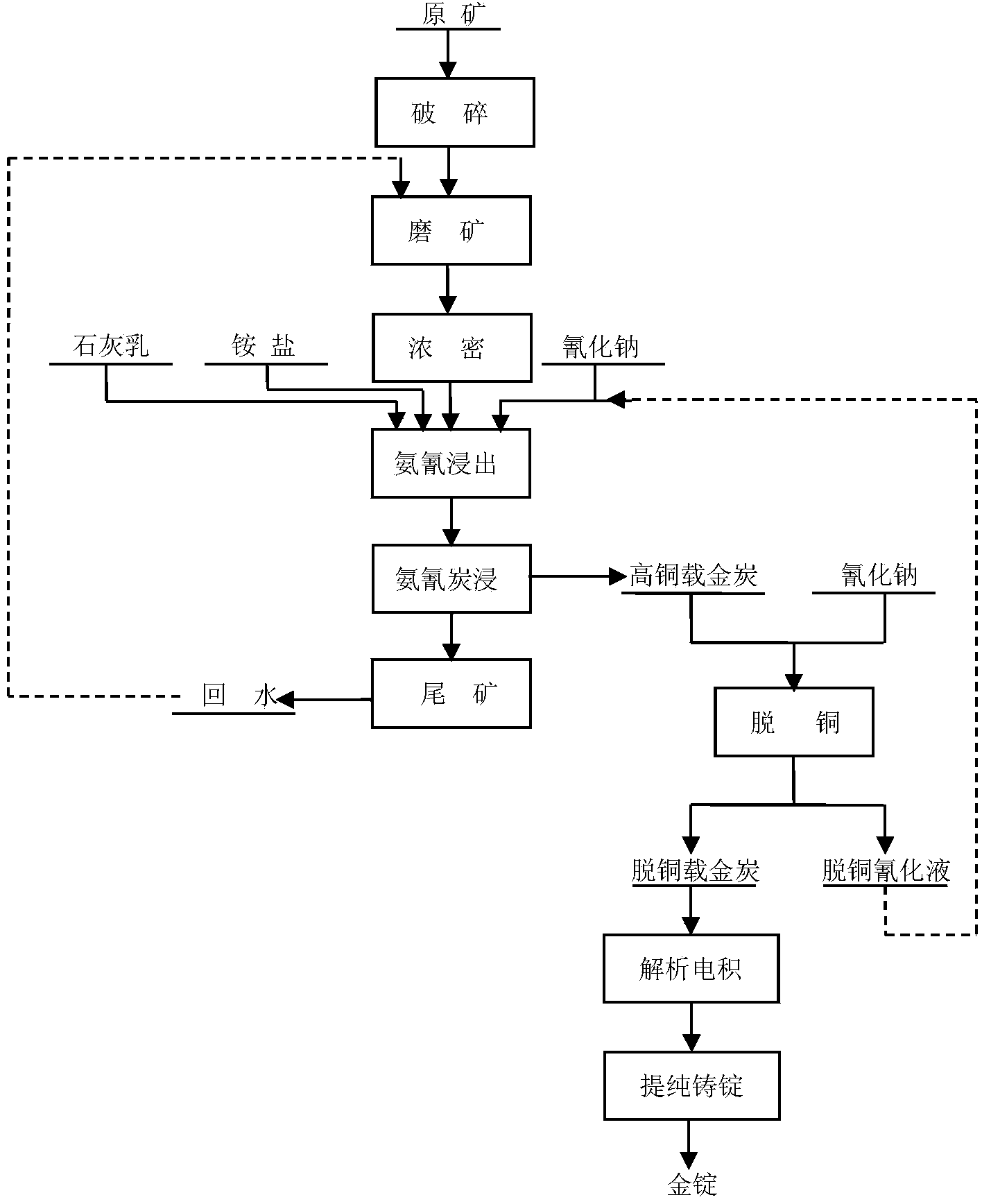

Image

Examples

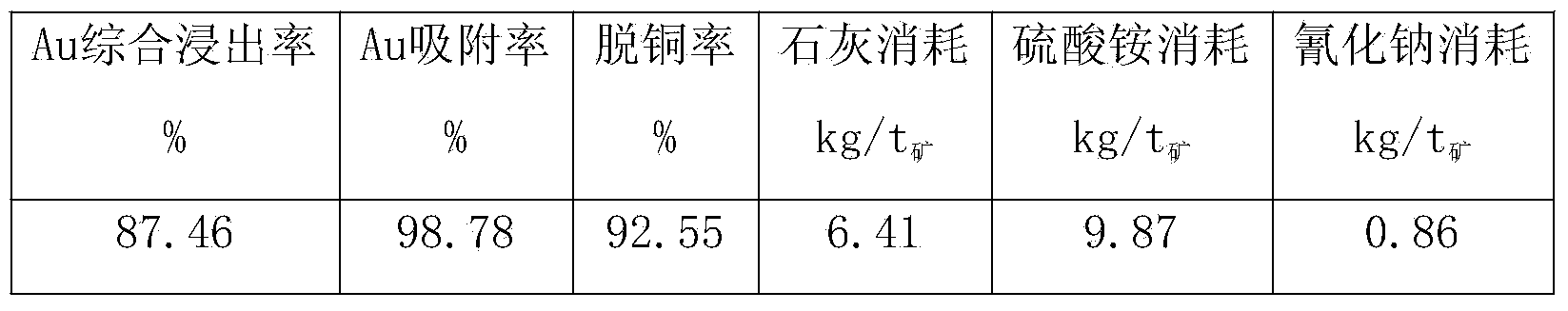

Embodiment 1

[0032] A foreign copper-bearing gold ore, with Au grade of 5.5g / t and Cu grade of 0.62%, belongs to the type of highly alkaline copper-containing gold oxide ore, and its treatment process is carried out according to the following steps and conditions:

[0033] The first step is crushing, grinding and thickening: After the ore is crushed to -250mm in one stage, it is graded through one stage of semi-autogenous grinding, two stages of ball milling and two stages of classification to produce -0.075mm particle size of 90% of the pulp. After the pulp is thickened by a thickener, A pulp with a concentration of 40% was obtained.

[0034] The second step of ammonia cyanide copper inhibition leaching: adding lime milk to the thickened pulp to control the pH between 10-11, adding ammonium sulfate to control the total ammonia concentration between 700-800ppm, adding decopper solution to control the total cyanide concentration to 200-300ppm After leaching for 48 hours, the gold leaching r...

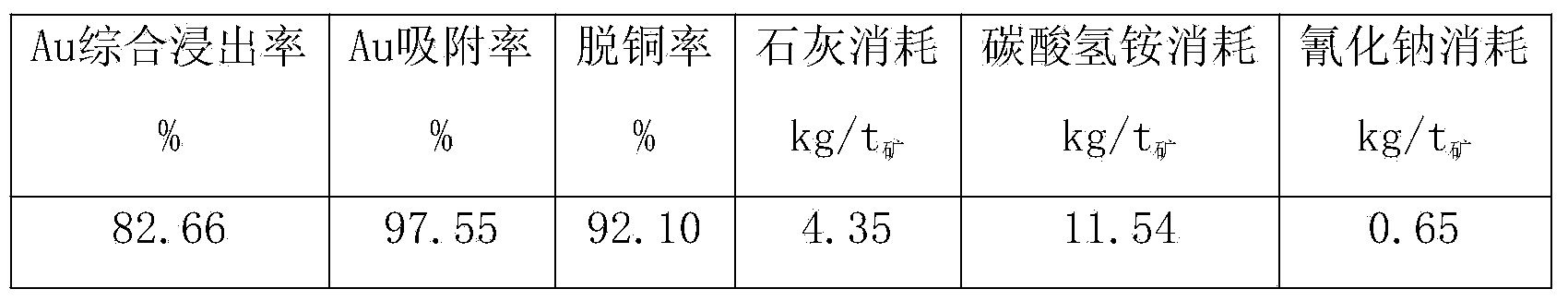

Embodiment 2

[0041] For a copper-bearing gold ore, the Au grade is 2.2g / t, and the Cu grade is 0.15%. The copper in this ore mainly exists in the form of copper oxide. The treatment process is carried out according to the following steps and conditions:

[0042] The first step is crushing, grinding and thickening: After the ore is crushed to -250mm in one stage, it is graded through one stage of semi-autogenous grinding, two stages of ball milling and two stages of classification to produce -0.075mm particle size of 85% of the pulp. After the pulp is thickened by a thickener, A pulp with a concentration of 48% was obtained.

[0043] The second step of ammonia cyanide copper inhibition leaching: Add lime milk to the dense pulp to control the pH between 9-10, add ammonium bicarbonate to control the total ammonia concentration between 400-500ppm, add decopper solution to control the total cyanide concentration to 50- Between 150ppm and leaching for 36 hours, the gold leaching rate is 67.38%. ...

Embodiment 3

[0050]A copper-bearing gold ore contains Au15.6g / t, Cu1.22%. Copper mainly exists in the form of chalcocite and copper blue. The treatment process is carried out according to the following steps and conditions:

[0051] The first step is crushing, grinding and thickening: After the ore is crushed to -250mm in one stage, it is graded through one stage of semi-autogenous grinding, two stages of ball milling and two stages of classification to produce pulp with a particle size of -0.075mm, which accounts for 95%. After the pulp is thickened by a thickener, A pulp with a concentration of 35% was obtained.

[0052] The second step is copper inhibition leaching with cyanide: add lime milk to the dense pulp to control the pH between 9.5-10.5, add ammonium carbonate to control the total ammonia concentration between 400-600ppm, add copper removal solution to control the total cyanide concentration between 50-200ppm After leaching for 48 hours, the gold leaching rate was 83.15%.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com