Movable stainless steel charcoal kiln

A technology of stainless steel and stainless steel frame, which is applied in carbonization furnace, special form of dry distillation, petroleum industry, etc. It can solve the problems of reduced yield of charcoal, environmental pollution, and inability to use, so as to improve the quality of finished products, reduce pollutants, and speed up heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be described in detail below in conjunction with the drawings and embodiments.

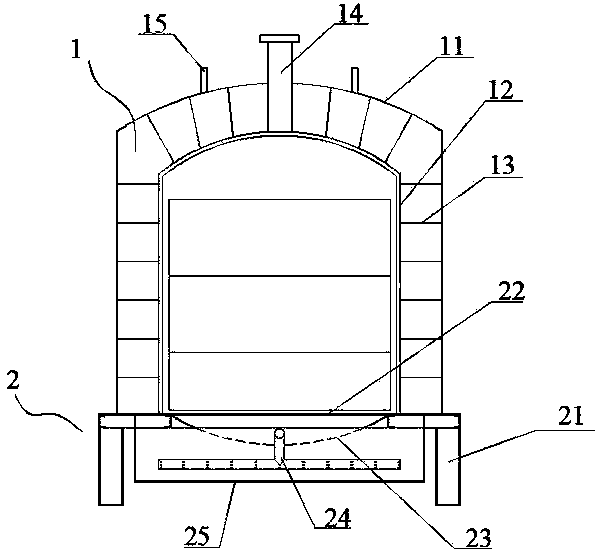

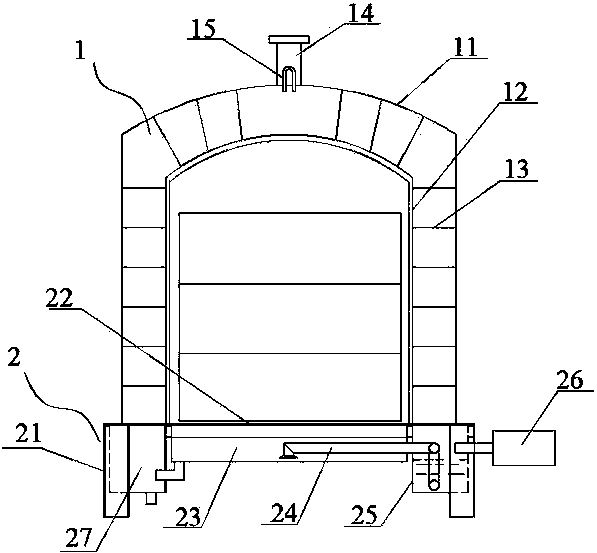

[0011] like figure 1 and figure 2 As shown, a stainless steel mobile charcoal kiln includes a mobile kiln body 1 and a base 2, the mobile kiln body 1 is covered on the base 2, and the mobile kiln body 2 is composed of an inner stainless steel liner 12, an outer layer The stainless steel frame 11, and the connecting rod 13 fixedly connecting the stainless steel liner 12 and the stainless steel frame 11 together, the stainless steel liner 12 and the top of the stainless steel frame 11 are provided with a flue 14, and the top of the stainless steel frame 11 is also provided with multiple 15 lifting rings.

[0012] The base 2 includes a charcoal kiln base 21. The charcoal kiln base 21 is composed of a column and a supporting plate. There is a hole in the middle of the supporting plate. Tube 25, exhaust fan 26, collection tube 27, the def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com