+/-1100kV direct current voltage divider

A technology of DC voltage divider and voltage equalizing ring, applied in the direction of voltage divider, etc., can solve problems such as premature aging of insulating materials, affecting equipment safety, and insufficient insulation performance, so as to achieve uniform distribution of internal field strength and reduce local Electric field strength, effect of satisfying insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

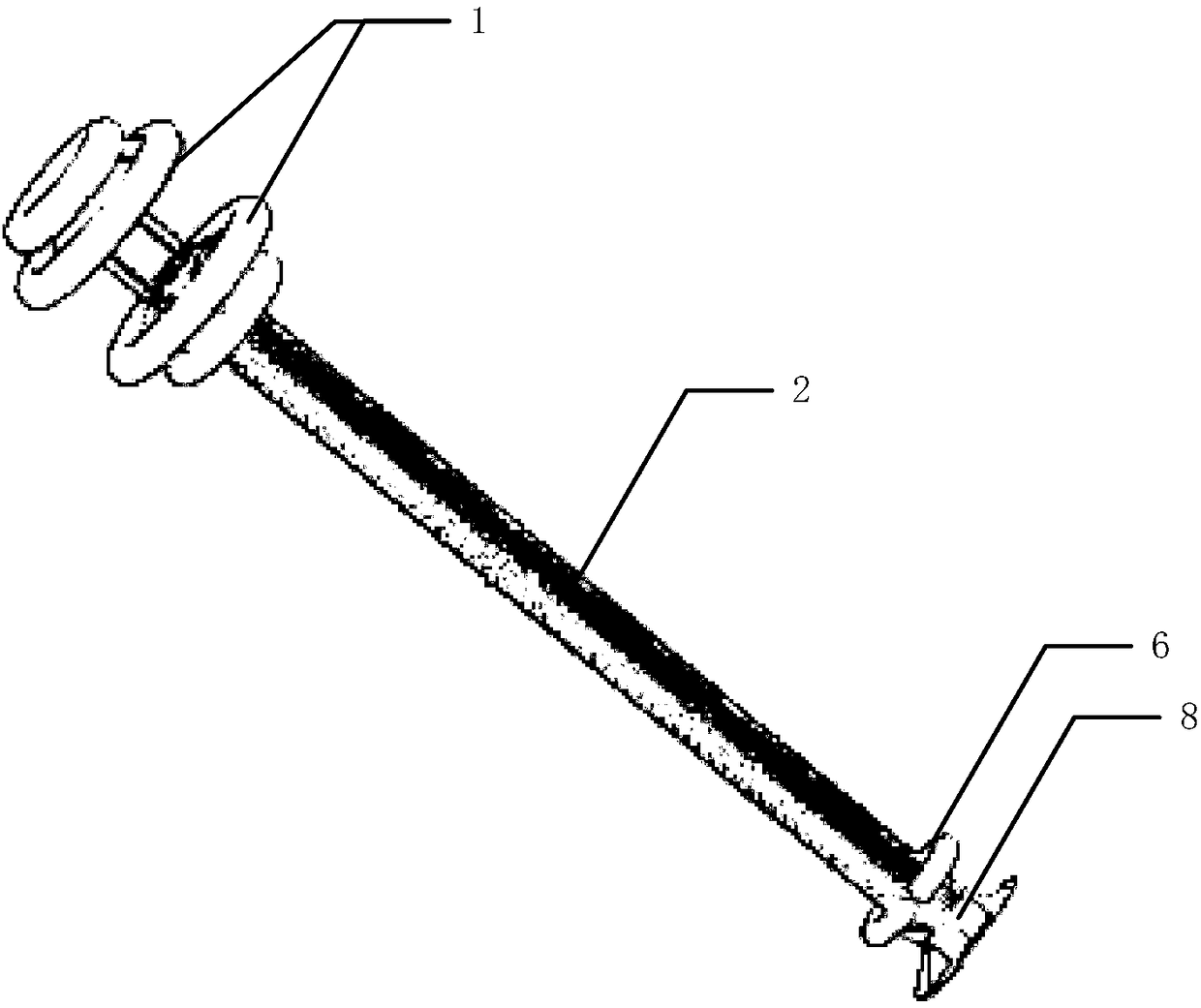

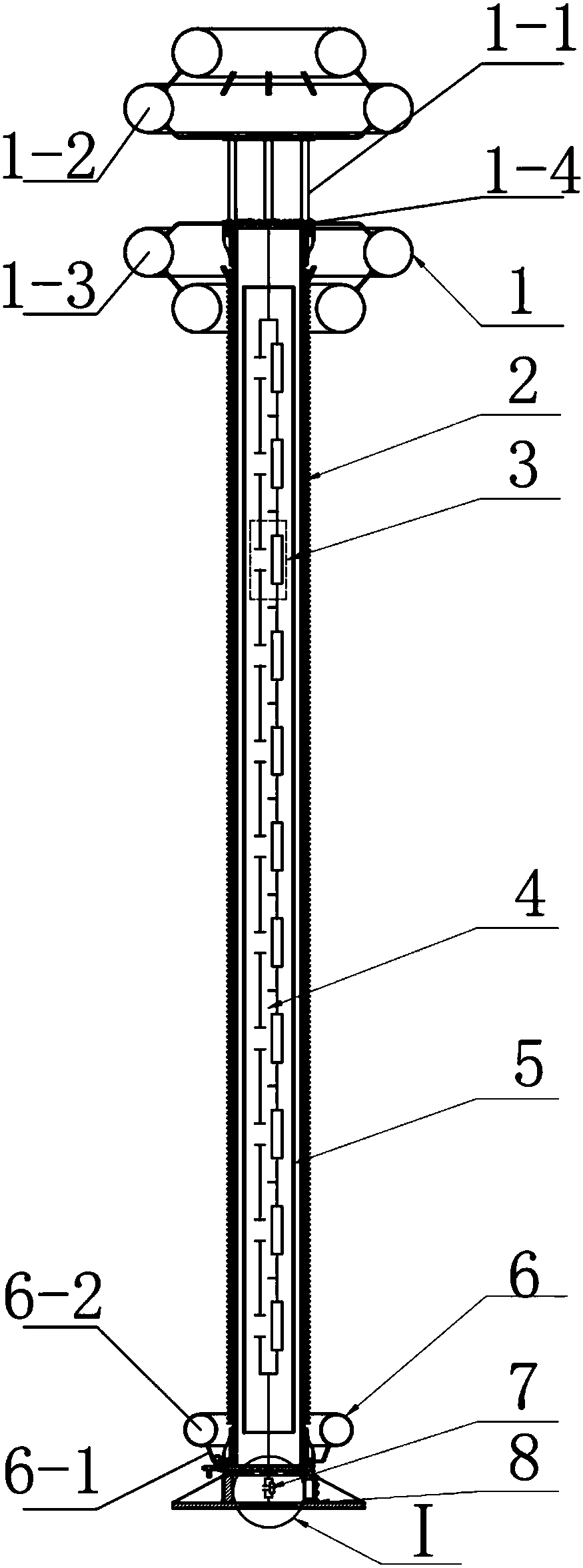

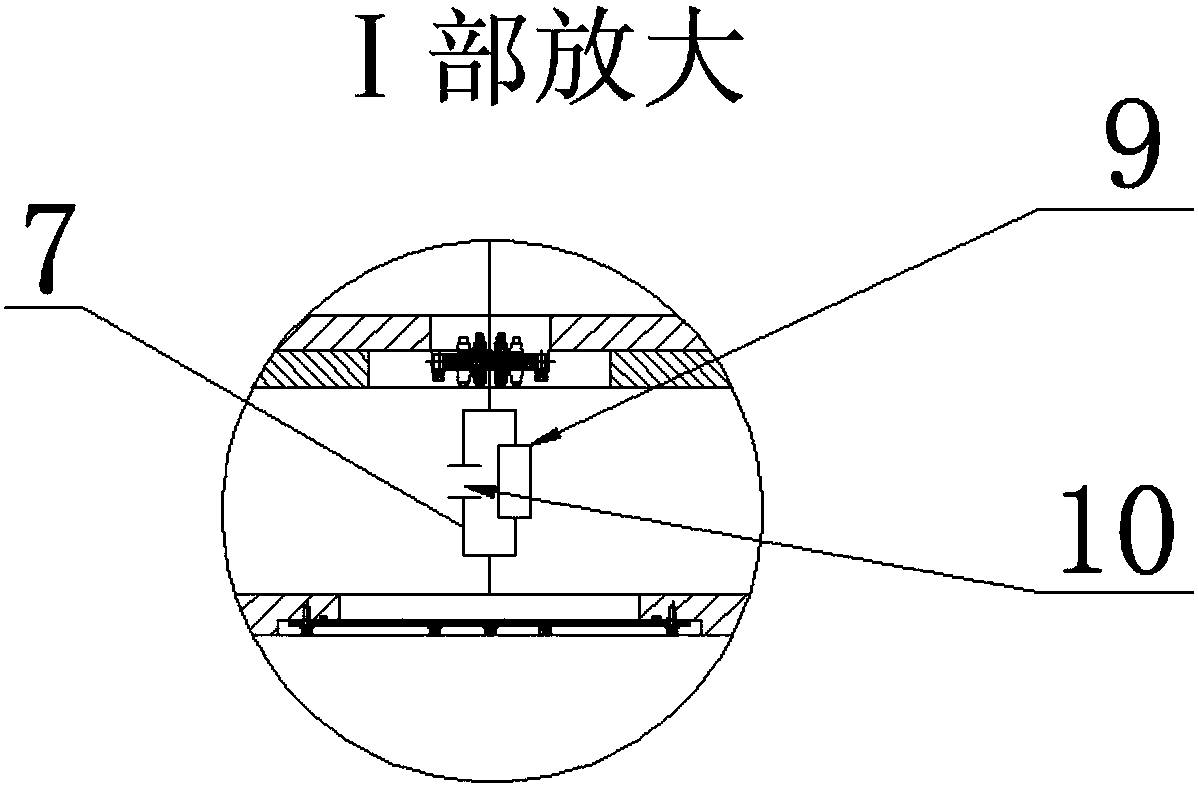

[0026] Such as figure 1 , 2 , 3, a ± 1100kV DC voltage divider, comprising a high-voltage end equalizing ring assembly 1, a high-voltage arm unit 4, a low-voltage end equalizing ring assembly 6, a low-voltage arm unit 7 and a base 8, the low-voltage arm unit 7 It is installed on the base 8, and one end of the low-voltage arm unit 7 is connected to the base 8 (ground terminal); the protection level of the base 8 is IP67.

[0027] It also includes a first insulating hollow bushing 2 and a second insulating inner tube 5, the second insulating inner tube 5 is set in the first insulating hollow bushing 2, and the high voltage arm unit 4 is set in the second insulating inner tube 5 , the base 8 is fixedly connected to the first insulating hollow bushing 2, and the voltage equalizing ring assembly 6 at the low-voltage end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com