Metallic reflection type insulating layer for nuclear class device and pipe

A metal reflective, thermal insulation layer technology, applied in pipeline protection, thermal insulation, mechanical equipment, etc., can solve the problem of poor thermal insulation effect, such as poor thermal insulation effect, and achieve the effect of improving thermal insulation effect, improving economy, and reducing the number of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

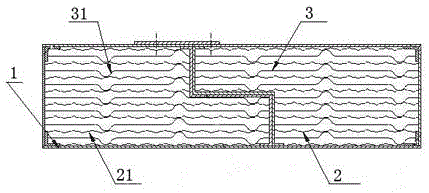

[0029] Such as Figure 1 to Figure 5 A metal reflective insulation layer for nuclear-level equipment and pipelines is shown. The reflective foil of this solution is arranged in the thermal insulation outer box 1, and the reflective foil includes the first reflective foil 2 and the second reflective foil 3 On the first reflective foil 2, hemispherical dimples I 21 and convex bubbles I arranged at intervals are pressed, and on the second reflective foil 3, hemispherical dimples with a diameter larger than dimples I 21 are also pressed. The diameters of II31 and convex II, concave II31 and convex II are larger than those of concave I21 and convex I, forming a structure of "one shallow and one deep" alternately stacked, which can better suppress the reflection of adjacent two layers Air convection heat exchange between the foils improves the heat preservation effect, the diameter of the concave bubble II 31 and the convex bubble II is larger, and the distance between the bottom of...

Embodiment 2

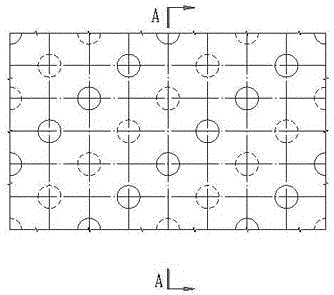

[0032] Such as Figure 1 to Figure 5 The metal reflective insulation layer for nuclear-level equipment and pipelines shown in this embodiment is optimized on the basis of the above embodiments, that is, the concave bubble I 21 and the convex bubble I are on the first reflective foil 2 arranged in a matrix.

[0033] The concave bubbles II 31 and convex bubbles II are arranged in a matrix on the second reflective foil 3 .

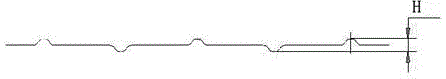

[0034]On the second reflective foil, the concave cell II 31 and the convex cell II with a hemispherical radius of SR5mm~SR15mm are pressed, and the layer height H after molding is 10mm to 30mm, that is, the height between the bottom of the concave cell II 31 and the top of the convex cell II is 10mm to 30mm; according to the thickness of the insulation layer and the insulation performance requirements, dimples II 31 and convex bubbles II with different diameters can be made to adjust the layer spacing and number of layers of adjacent reflective foils in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com