Aluminum foil woven fabric and preparation method thereof

A woven fabric, aluminum foil technology, applied in chemical instruments and methods, flexible coverings, adhesive types, etc., can solve the limited application scope and economic benefits, reduced tear and puncture resistance, waterproof and breathable performance Not ideal and other problems, to achieve the effect of improving waterproof and breathable performance, improving flame retardant effect, and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

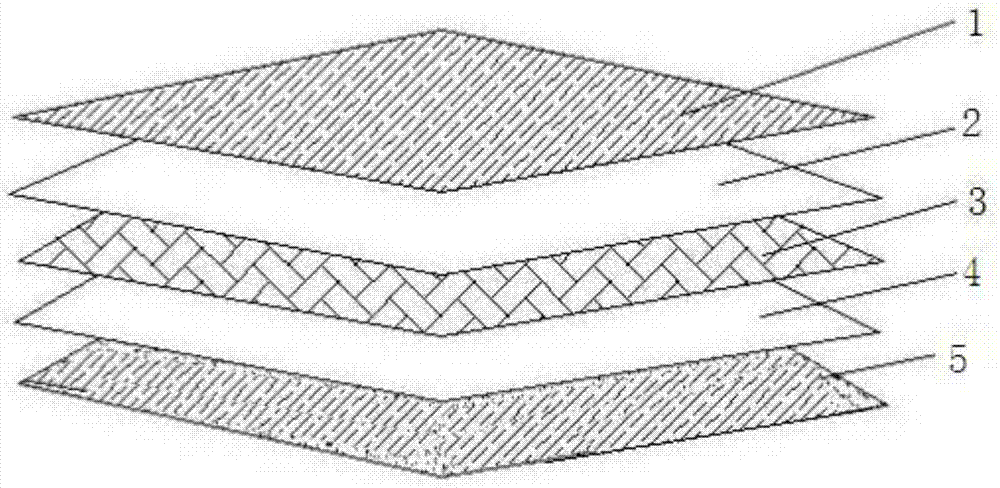

[0018] Such as figure 1 As shown, an aluminum foil woven cloth includes an upper aluminum foil layer 1, a flame retardant adhesive layer 2, a flame retardant woven cloth layer 3, a coating layer 4 and a lower aluminum foil layer 5 arranged sequentially from top to bottom. The aluminum foil layer is made of high-purity aluminum foil with 99% aluminum content, the flame-retardant adhesive layer 2 is made of polyurethane composite glue added with calcium carbonate, and the flame-retardant woven cloth layer 3 is woven with low-pressure high-density polyethylene with 22% flame retardant Cloth, coating layer 4 with low-density polyethylene particles, the upper surface of the flame-retardant woven cloth layer is compounded with the upper aluminum foil layer through polyurethane composite glue, and the lower surface of the flame-retardant woven cloth layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com