On-site spraying and filling fabrication method for inorganic fiber wall

A production method and technology of inorganic fibers, which are applied in the direction of walls, building components, buildings, etc., can solve the problems of poor thermal insulation effect, large labor consumption, low flame retardant and fire resistance performance, etc., to improve thermal insulation and sound insulation performance, save process and The effect of shortened man-hours and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

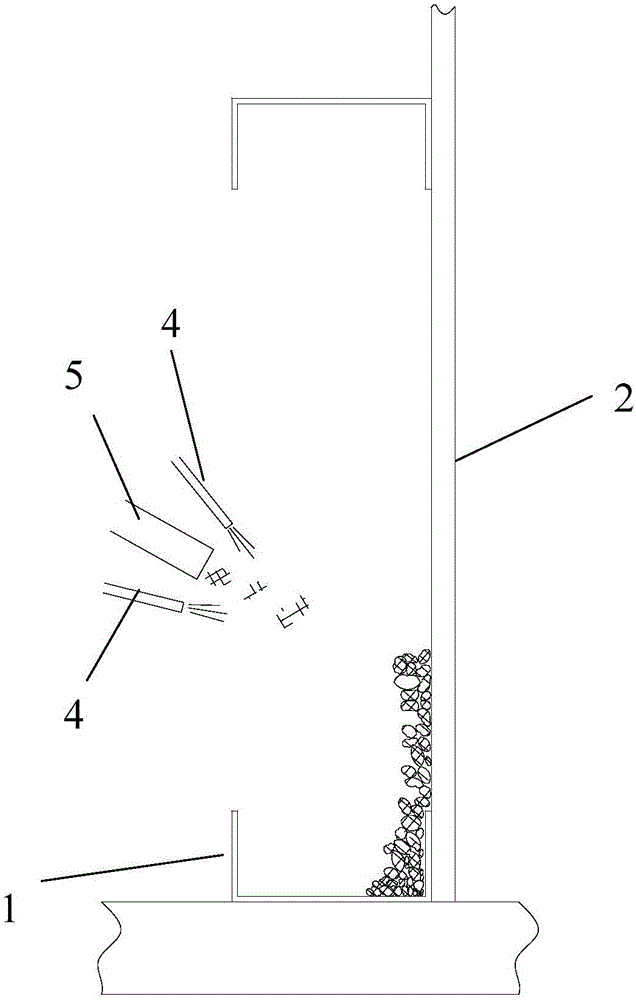

[0027] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

[0028] The invention provides a method for quickly fabricating a wall body with excellent thermal insulation and sound insulation properties, and the wall body is fabricated between a top plate and a bottom plate. The production method mainly includes four steps, and the specific steps are as follows:

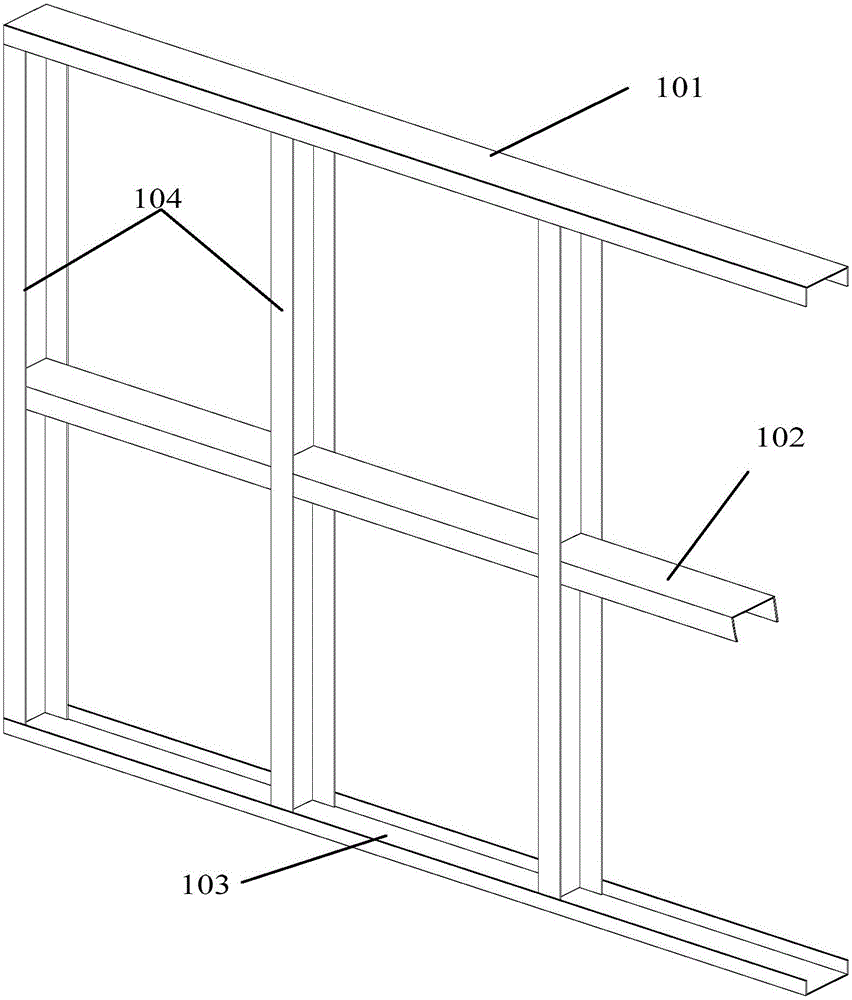

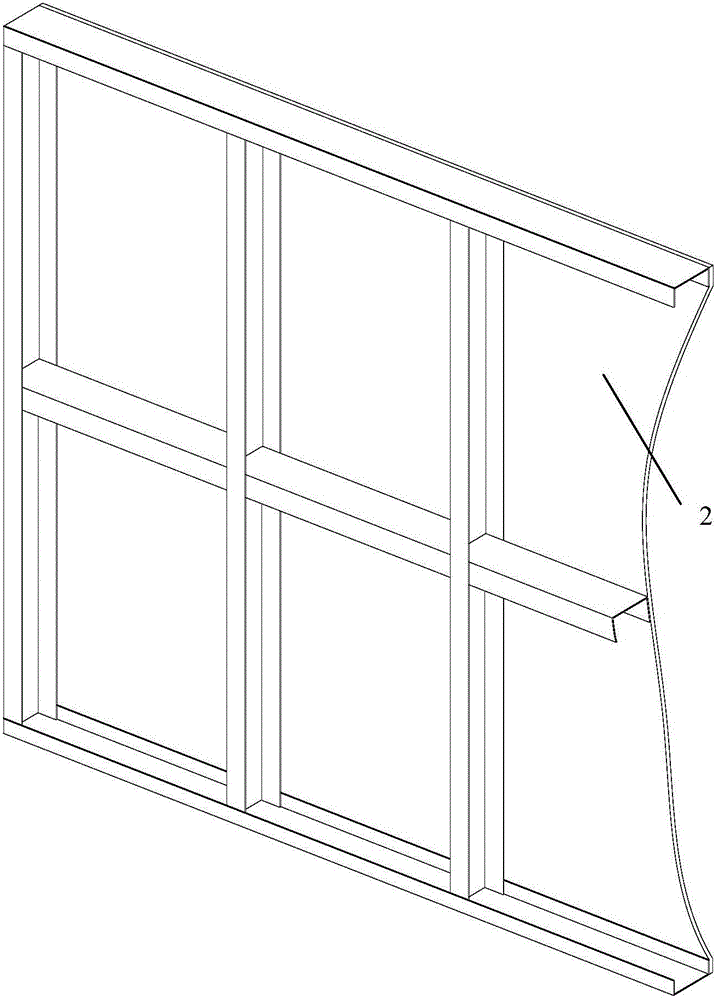

[0029] First of all, keels are installed horizontally and vertically between the top plate and the bottom plate to form the inner support of the wall and provide support for the wall. figure 1 A schematic diagram of the support inside the wall, such as figure 1 As shown, the wall is supported by a plurality of horizontal and vertical keels assembled, and its keels include a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com