Temperature detecting circuit

A temperature detection circuit, temperature value technology, applied in thermometers, thermometers with analog-to-digital converters, and heat measurement, etc., can solve problems such as difficulties, achieve the effect of suppressing cost increase, satisfying insulation and high responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

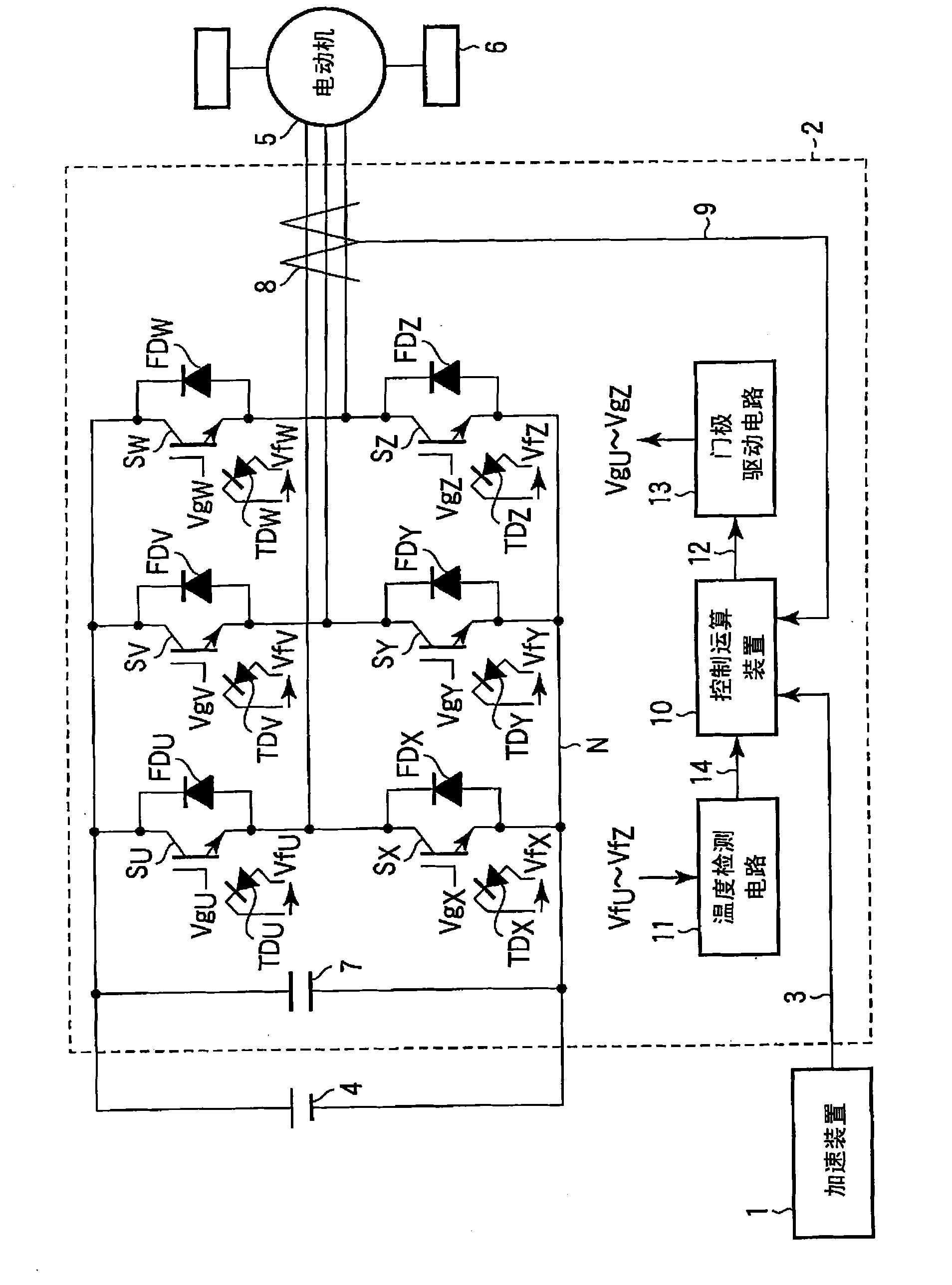

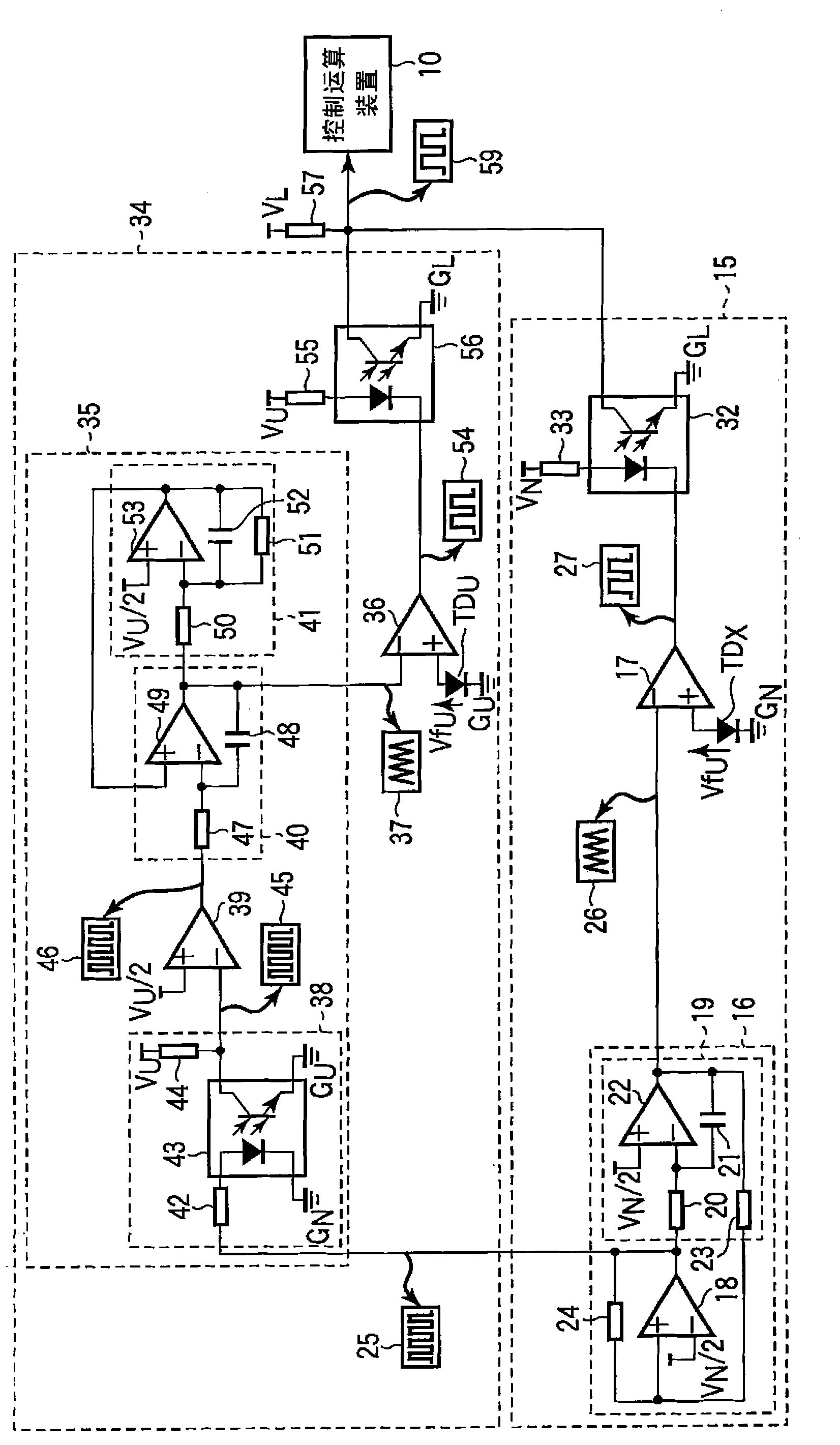

[0033] figure 2 It means measuring SW element S U , S X A diagram of the structure of the temperature detection circuit of the temperature. Temperature sensor TD U and TD X close to the SW element S U , S X Since it is provided, a voltage of several hundred V or more is applied to the SW element similarly to the SW element depending on the on / off state of the SW element. The temperature detection circuits including the temperature sensor need to be insulated from each other so as not to be destroyed even at such a high voltage.

[0034] First, explain the SW element SX The details of the temperature detection circuit 15. The temperature detection circuit 15 takes power supply voltage V N , Reference potential G N It works and includes a triangular wave generating circuit 16 and a comparator 17.

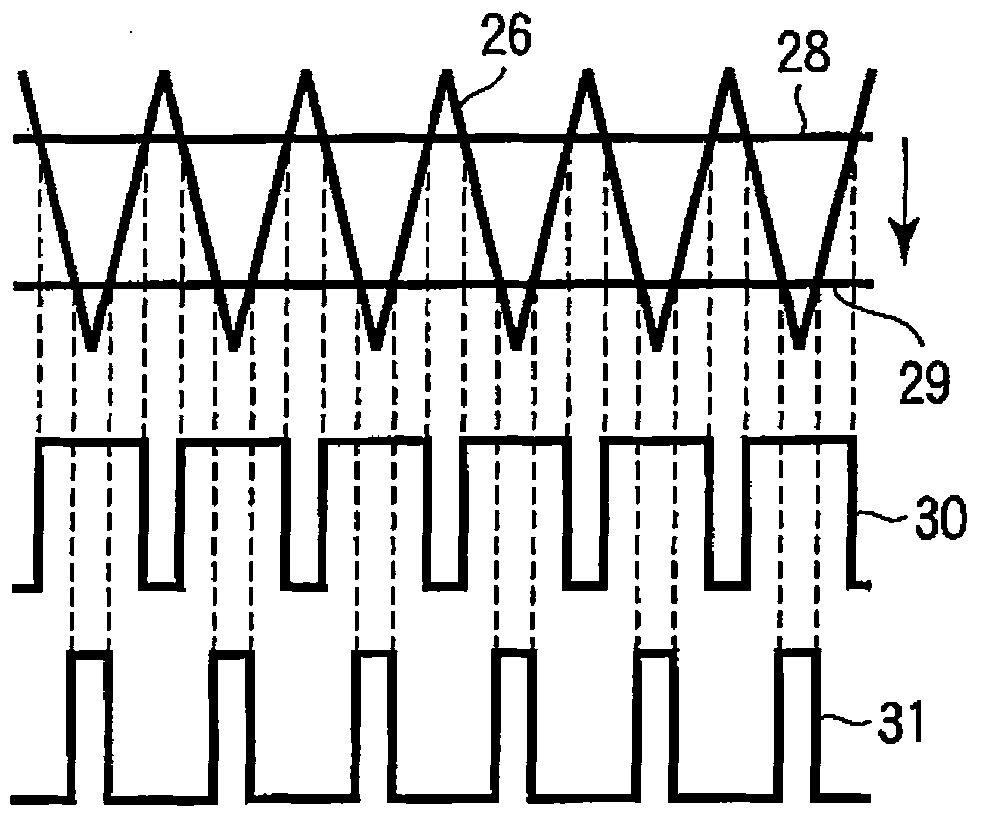

[0035] The triangular wave generating circuit 16 includes a comparator 18 and an integrating circuit 19 . The integrating circuit 19 is configured using a resistor 20 , a ...

Embodiment 2

[0053] Actually, the temperature detection accuracy of the SW element decreases due to the dispersion of the temperature sensor and the detection circuit. In this embodiment, a method for improving the temperature detection accuracy when the inverter 2 is operated will be described.

[0054] If each temperature sensor TD U ~TD Z If there is a dispersion in accuracy or the like in the temperature detection circuit, a dispersion will also occur in the relationship of "temperature / duty ratio" of the SW element. If the same "SW element temperature / duty ratio" relationship is uniformly adopted for the input PWM signals, the detection accuracy of the SW element temperature will decrease. If using respectively matched with the temperature sensor TD U ~TD Z The relationship between the SW element temperature / duty ratio can avoid the problem of dispersion, but it is necessary to determine which SW element the PWM signal of the SW element with the highest temperature input to the co...

Embodiment 3

[0057] Figure 8 This is an example in which the PWM signal of the SW element with the highest temperature is input to the control operation device 10 without synchronizing the triangular waves generated by a plurality of temperature detection circuits. In this embodiment, the measurement SW element S U , S X The case of temperature as an example.

[0058] Circuits 67 and 68 having the same configuration as the temperature detection circuit 15 described in Embodiment 1 are respectively provided in the temperature sensor TD. U 、TD X middle. The PWM signals 69 , 70 isolated from the high voltage side are input to the data selector 71 . The PWM signal 69 is input to an inverting input terminal of the comparator 74 through an RC filter composed of a resistor 72 and a capacitor 73 . Similarly, the PWM signal 70 is input to a non-inverting input terminal of the comparator 74 through a filter of a resistor 75 and a capacitor 76 . The time constant of the filter circuit is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com