Inorganic thermal mortar external wall insulation system

A technology of inorganic thermal insulation mortar and external wall thermal insulation, which is applied in the field of external wall thermal insulation system and inorganic thermal insulation mortar external wall thermal insulation system, can solve the problem that the wall cannot meet thermal insulation, fire prevention, sound insulation, strength, anchoring and other problems at the same time, and achieve high anchoring strength. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

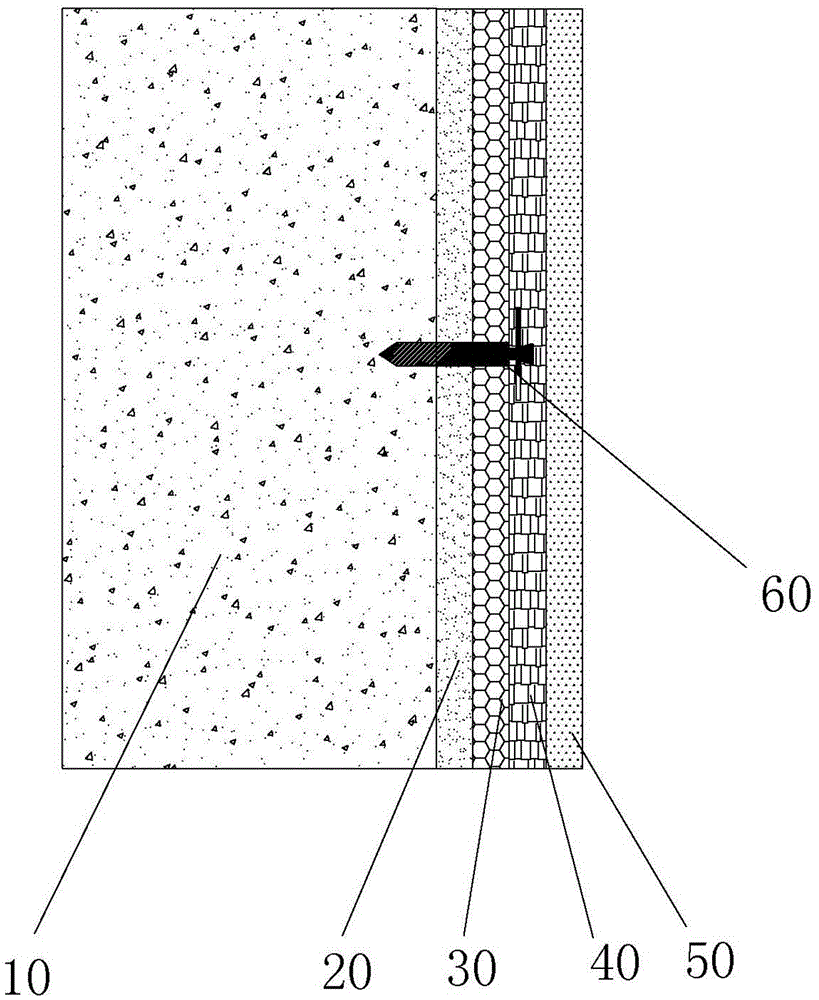

[0040] Such as Figure 1-2 As shown, the inorganic thermal insulation mortar external wall thermal insulation system includes a concrete wall or masonry wall 10 covered with multiple coatings, and the multiple coatings sequentially include an interface mortar layer 20, an inorganic light aggregate thermal insulation mortar layer from inside to outside 30. Plastering anti-cracking mortar layer 40 and finish layer 50. The interface mortar layer 20 is a brushing type interface mortar layer or a scraping type interface mortar layer. The plastering anti-cracking mortar layer 40 has a built-in galvanized steel wire mesh or glass fiber mesh cloth.

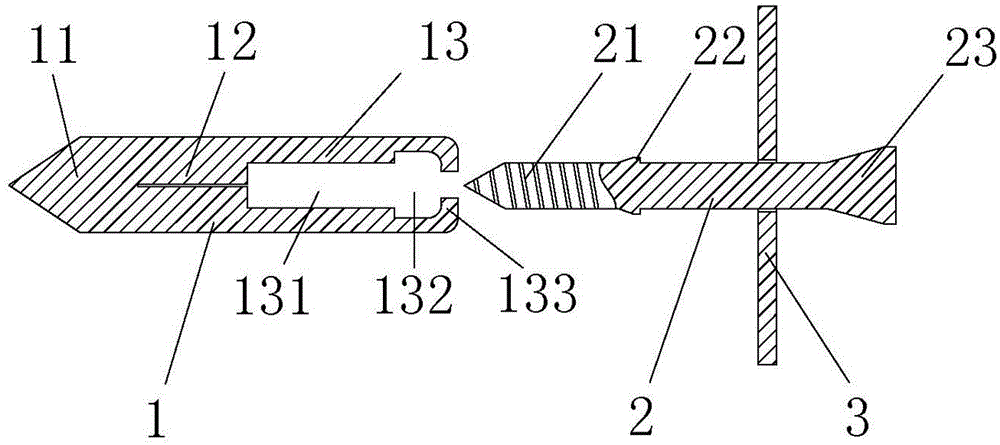

[0041] The galvanized steel wire mesh or fiberglass grid cloth is reinforced to the concrete wall or masonry wall 10 by anchors; the anchors include expansion tubes 1 made of engineering plastics and act on the inside of the expansion tubes 1 Thereby the self-tapping screw 2 that makes described expansion tube 1 expand, and described ex...

Embodiment 2

[0044] Such as figure 1 with 3 As shown, the inorganic thermal insulation mortar external wall thermal insulation system includes a concrete wall or masonry wall 10 covered with multiple coatings, and the multiple coatings sequentially include an interface mortar layer 20, an inorganic light aggregate thermal insulation mortar layer from inside to outside 30. Plastering anti-cracking mortar layer 40 and finish layer 50. The interface mortar layer 20 is a brushing type interface mortar layer or a scraping type interface mortar layer. The plastering anti-cracking mortar layer 40 has a built-in galvanized steel wire mesh or glass fiber mesh cloth.

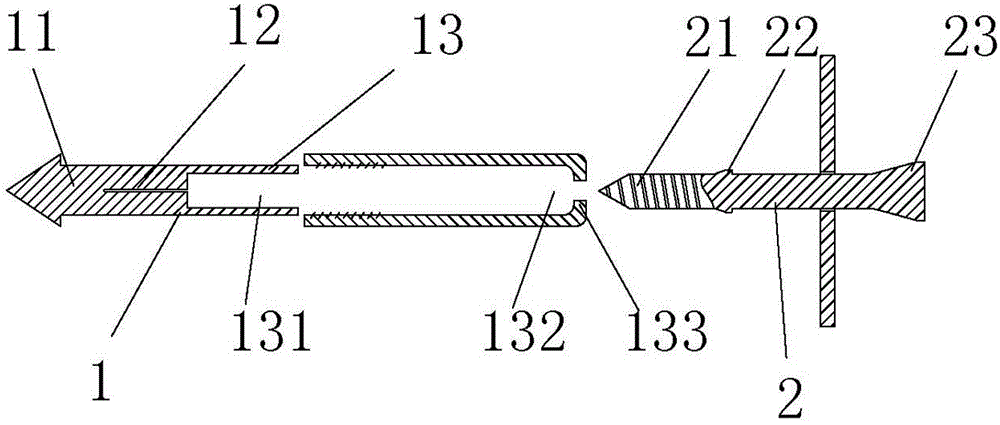

[0045]The galvanized steel wire mesh or fiberglass grid cloth is reinforced to the concrete wall or masonry wall 10 by anchors; the anchors include expansion tubes 1 made of engineering plastics and act on the inside of the expansion tubes 1 Thereby the self-tapping screw 2 that makes described expansion tube 1 expand, and describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com