Laminate adhesive, stack using the same, and secondary battery

A technology of adhesives and solvents, applied in the field of adhesives for lamination, can solve problems such as low electrolyte resistance, interlayer peeling, and inability to be used as a sealing film, and achieve excellent adhesiveness and moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Add 50 parts of modified polyolefin resin GMP7550E (manufactured by LOTTECHEMICAL), 50 parts of Auroren350S, 0.05 parts of Curezol2E4MZ, 6.0 parts of DenacolEX-850L, 320 parts of methylcyclohexane, 40 parts of ethyl acetate, 40 parts Parts of isopropanol (IPA) and fully stirred, with a rod coater at 5g / m 2 (Dry type) After coating on an aluminum foil and drying at 80 degreeC for 1 minute, it bonded with the CPP film at 100 degreeC, and produced the coated object.

[0087] Thereafter, the initial adhesive strength was measured after aging at 60° C. for 5 days.

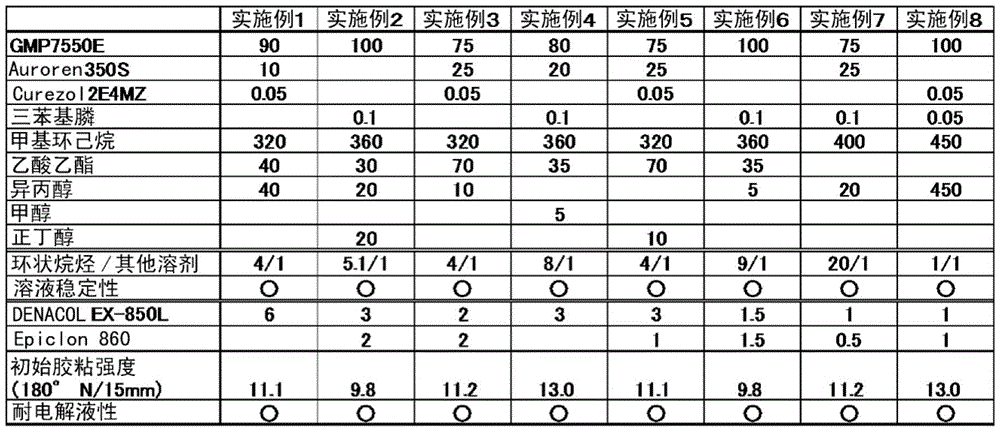

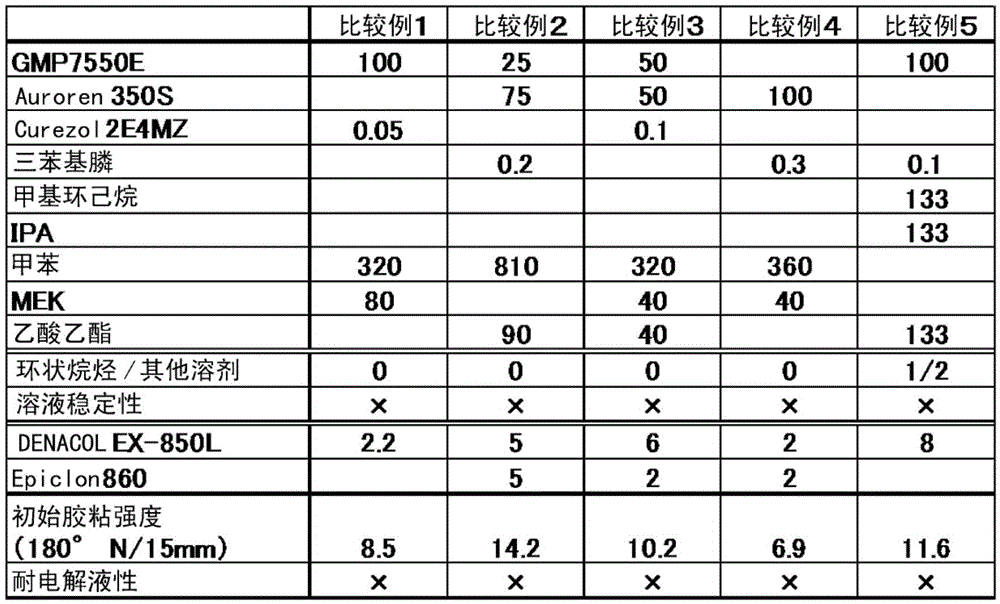

[0088] Other adhesives were blended as shown in Table 1, and adhesives were produced in the same manner as in Example 1. Furthermore, each laminated body was produced by the same manufacturing method as the laminated body 1.

[0089] Table 1 shows the results of evaluating the adhesive performance and electrolyte resistance of the laminates obtained in each example. In addition, the conditions of each performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com