Intelligent printing unit carrying out multi-mode printing based on offset print platform

A multi-mode and platform technology, applied in the direction of lithographic rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of inability to select functional components, complicated process, inability to realize multi-process and multi-functional printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

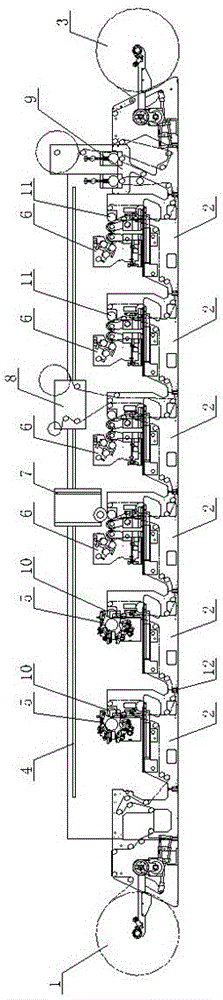

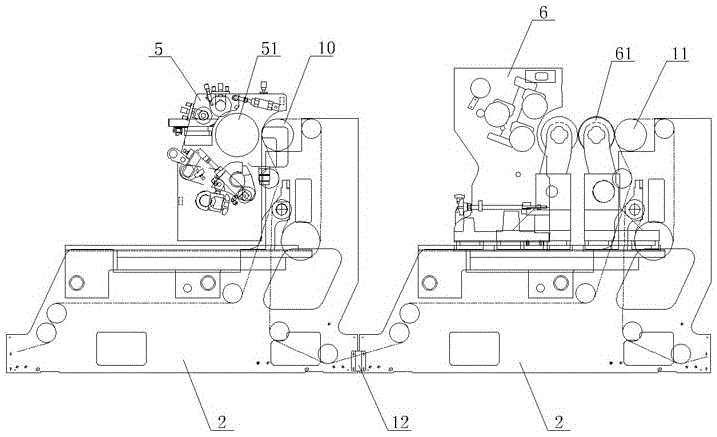

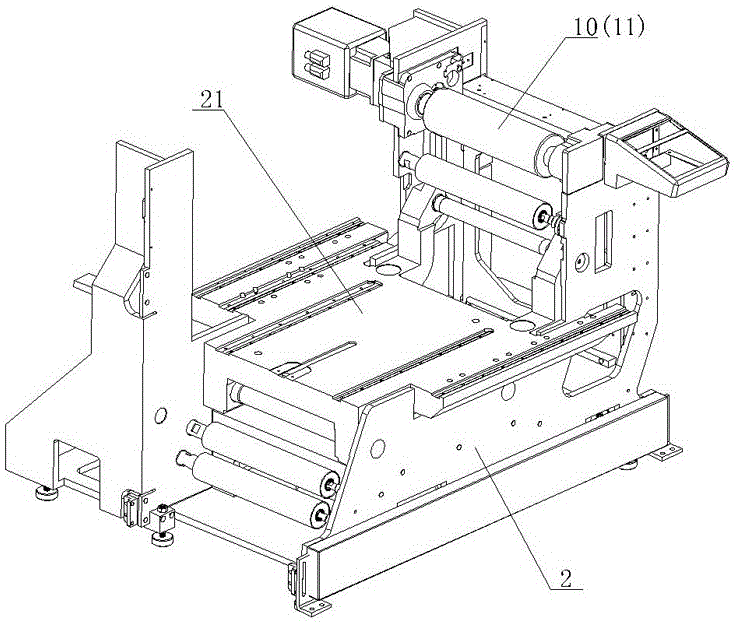

[0014] As shown in the figure, the intelligent printing unit for multi-mode printing based on the offset printing platform of the present invention includes an unwinding part 1, a winding part 3 and an offset printing platform. The seats 2 are fixedly connected by the connecting plate 12, the flexo printing head part 5 is installed on the two groups of printing seats 2 on the left, the offset printing head part 6 is installed on the four groups of printing seats 2 on the right, the offset printing head part 6, and the flexo printing head Part 5 can be interchangeably arranged on each print base 2. The offset print head part 6 and the flex print head part 5 adopt a separate modular design. Each print base 2 is provided with a unified installation platform 21. The offset print head part 6 or the flexographic printing head part 5 is installed or disassembled on the installation platform 21 as a whole, the offset printing head part 6 includes the offset printing plate roller 61 but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com