A rotary wheel type automatic cold ironing machine

A fully automatic, wheel-type technology, applied to rotary printing machines, printing machines, printing, etc., can solve the problems of poor convenience in use and maintenance, lower production efficiency, and large space occupation, and achieve strong practical value and market promotion Value, simple and compact structure, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

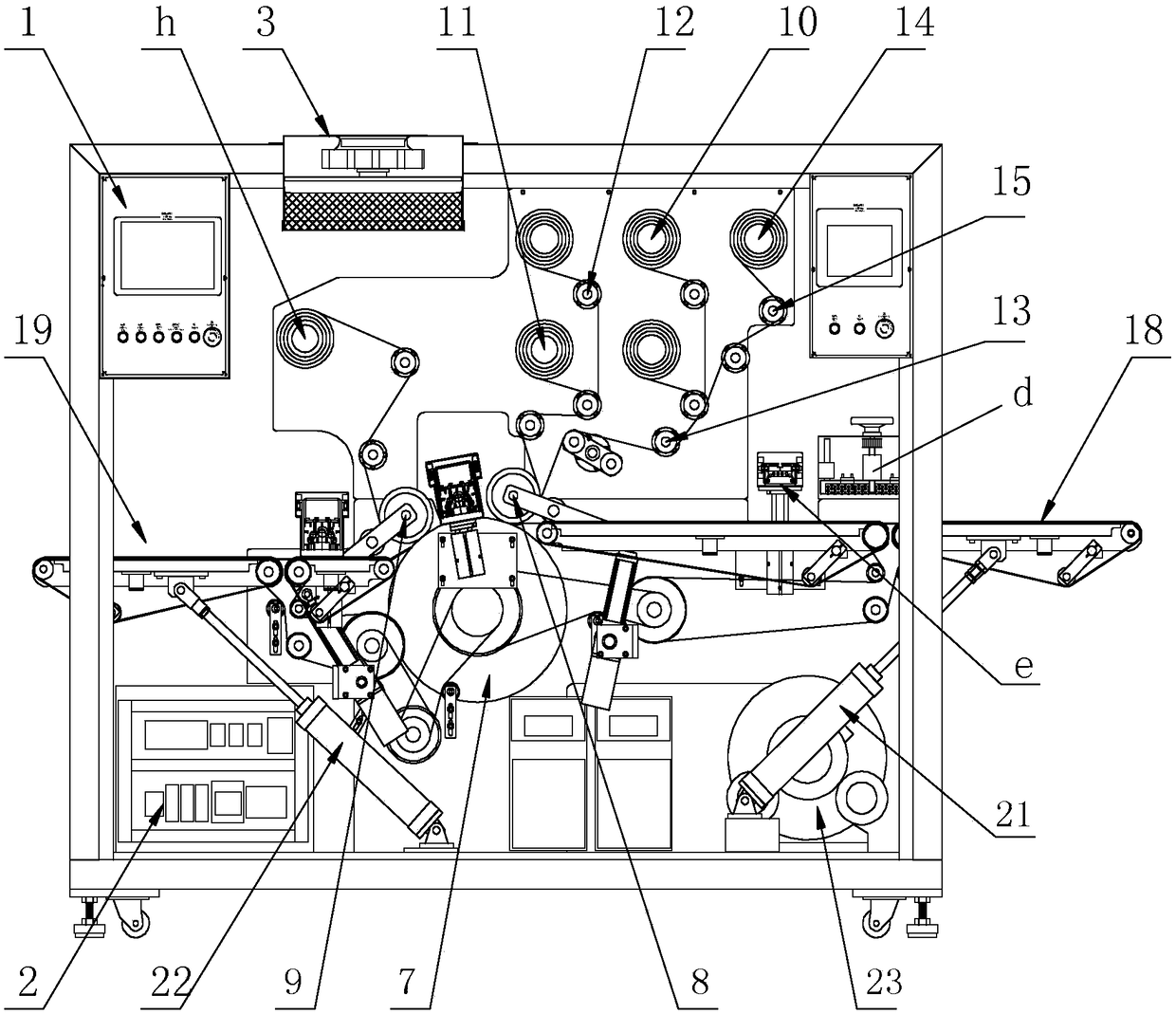

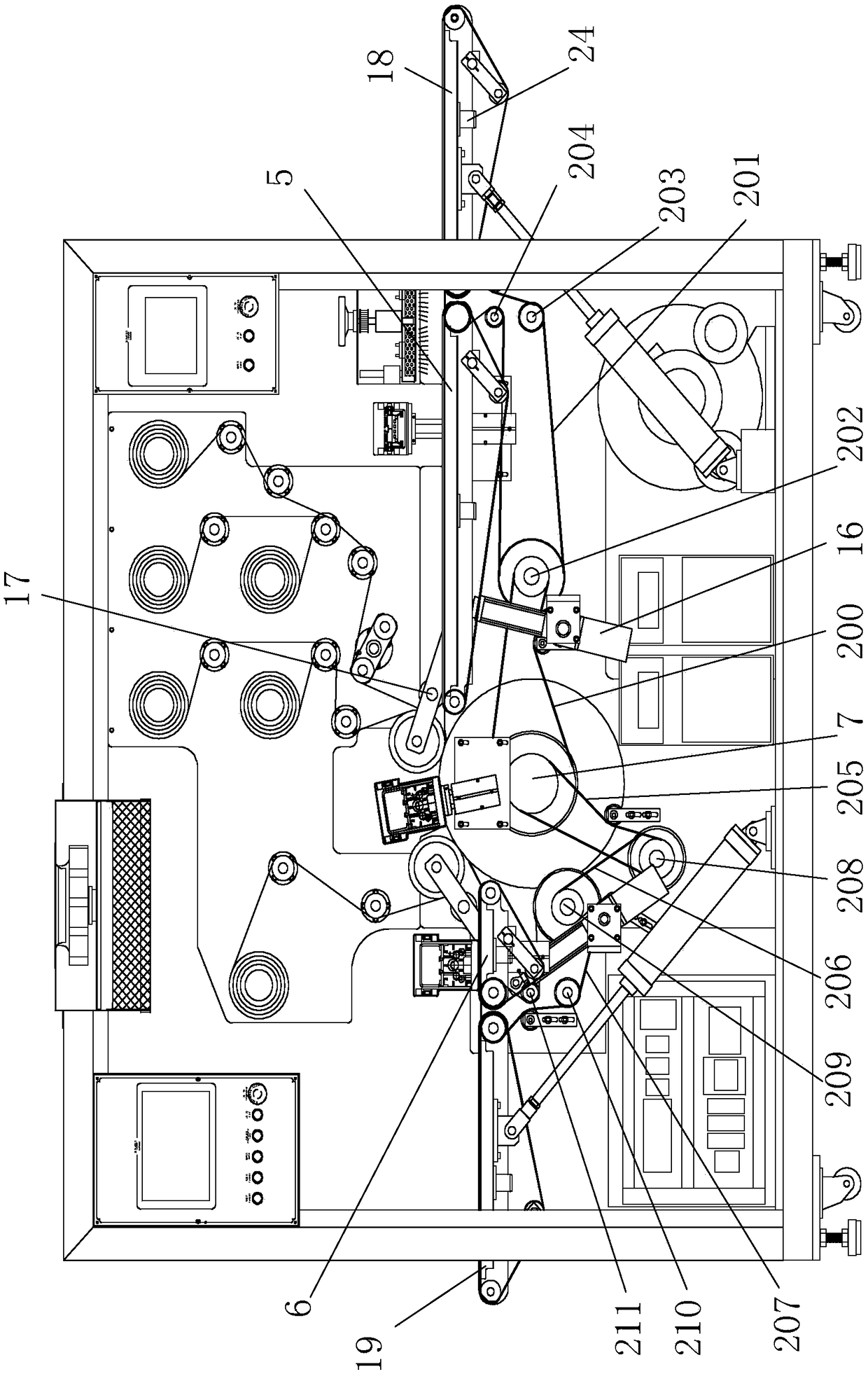

[0048] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

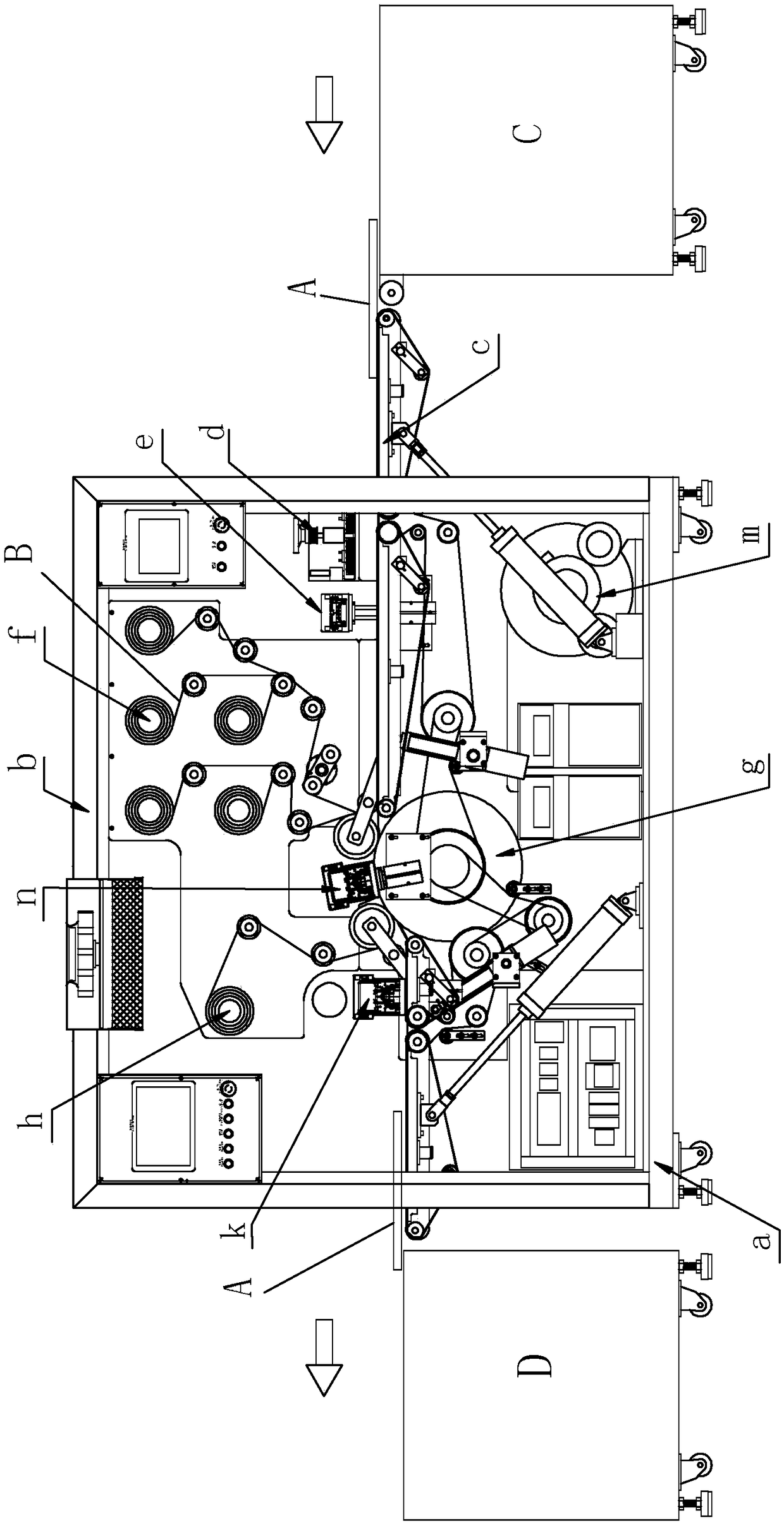

[0049] Such as Figure 1 to Figure 5 As shown, a kind of rotary wheel type fully automatic cold ironing machine provided by the present embodiment comprises:

[0050] Frame body a is equipped with an electrical control assembly that plays a core control role on the frame body a (it is mainly composed of the operation panel 1 installed on the frame body a, the electrical control assembly installed in the frame body a) Control box 2 and corresponding electric circuit etc. form);

[0051] The sealed box b is mainly used to ensure the working environment of the entire machine's internal printing, so as to create a relatively closed space and block the pollution of the external environment. It is installed on the frame body a, and a new The air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com