Double-positioning cold-ironing system

A double-positioning, cold foiling technology, applied in printing, rotary printing presses, printing presses, etc., can solve the problems of inability to manufacture, no technical solution proposed, and insufficient utilization of metal coating, and achieve the effect of saving cold foiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

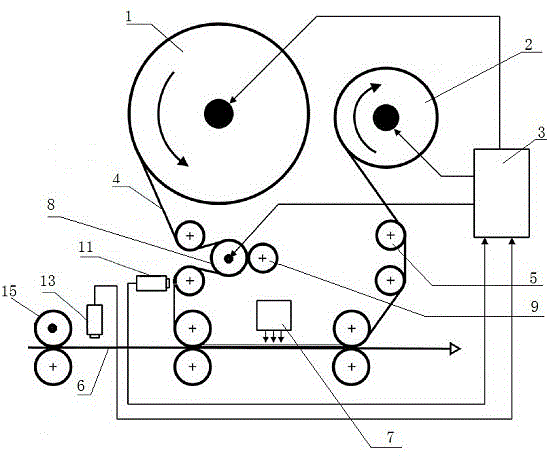

[0037] 1. Design and installation of mechanical and electrical systems.

[0038] In advance, according to the customer's needs, survey and map the installation position of the printing machine equipped with the positioning cold ironing system of the present invention (including the installation method of fixed position and moving guide rail). It is required to survey and map the installation position of the synchronous encoder (15) and the installation position of the electric eye B (13) for reading the printed matter cursor (12).

[0039] Design and install the base, guide rail and bracket according to the location and size of the survey.

[0040] Overall assembly after machining, electrical system assembly.

[0041] The positioning cold ironing system of the present invention is powered on and tested before leaving the factory.

[0042] Installation to customer's factory.

[0043] Install the dual-position cold stamping system of the present invention on the printing mach...

Embodiment 2

[0054] see figure 1 As in the previous example, the dual-position cold ironing system of the present invention is designed and manufactured, and installed on the printing press according to the position previously surveyed and mapped. Connect the synchronous encoder (15) to the main drive shaft of the printing press to detect the speed of the printing press. The electric eye B (13) for reading the printed matter cursor (12) is installed on the existing flexo self-adhesive label printing machine.

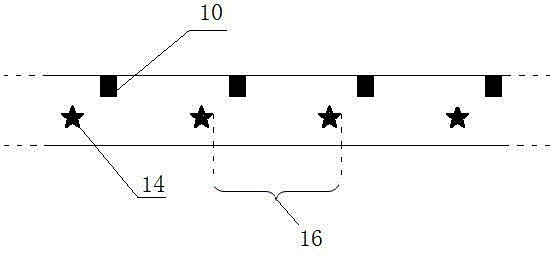

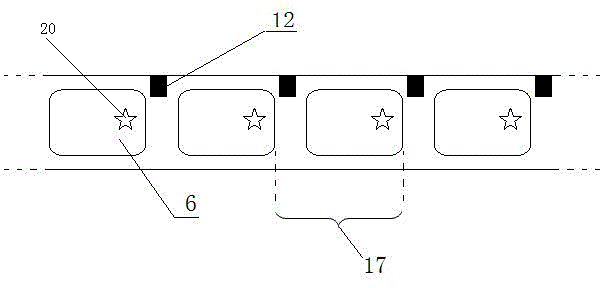

[0055] Such as image 3 As shown, the printed matter (6) ready to be printed is designed. The printed matter (6) is a rectangular rounded self-adhesive label of 104mm×64mm. The typesetting length y (17) of a label is 108.03mm, and the same position on the edge of each label A 6mm×4mm black print cursor (12) is printed, and the distance between the cursors is also 108.03mm. The printed matter (6) is printed with an existing flexographic self-adhesive label printing machine.

[00...

Embodiment 3

[0062] see figure 1 As in the previous example, the dual-position cold ironing system of the present invention is designed and manufactured, and installed on the printing press according to the position previously surveyed and mapped. Connect the synchronous encoder (15) to the main drive shaft of the printing press to detect the speed of the printing press. The electric eye B (13) for reading the printed matter cursor (12) is installed on the existing flexo self-adhesive label printing machine.

[0063] Such as image 3 As shown, the printed matter (6) to be printed is designed. The printed matter (6) is a rectangular rounded self-adhesive label of 104mm×64mm, the label spacing y (17) is 108mm, and a 6mm label is printed at the same position on the edge of each label ×4mm black print cursors (12), the distance between the cursors is also 108mm. The printed matter (6) is printed with an existing flexographic self-adhesive label printing machine.

[0064] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com