Gift box packing cold-ironing device and processing technology thereof

A gift box and cold stamping technology, which is applied in printing, rotary printing machines, printing machines, etc., can solve the problems of whitening, low production capacity and efficiency, and gold loss, and achieve the effects of expanding application scenarios, improving bronzing ink accumulation, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

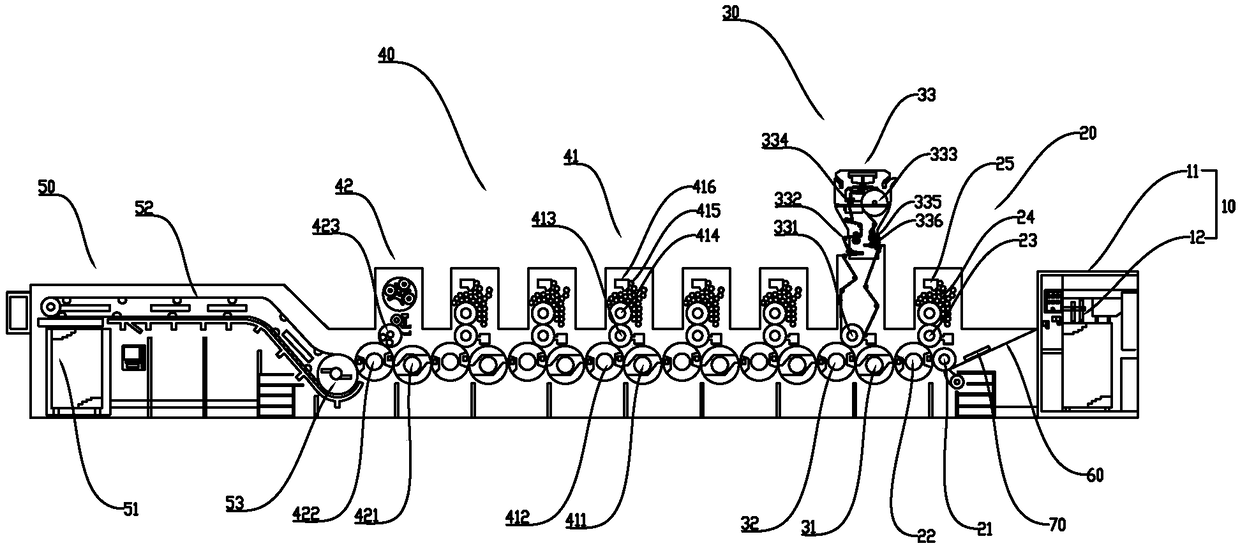

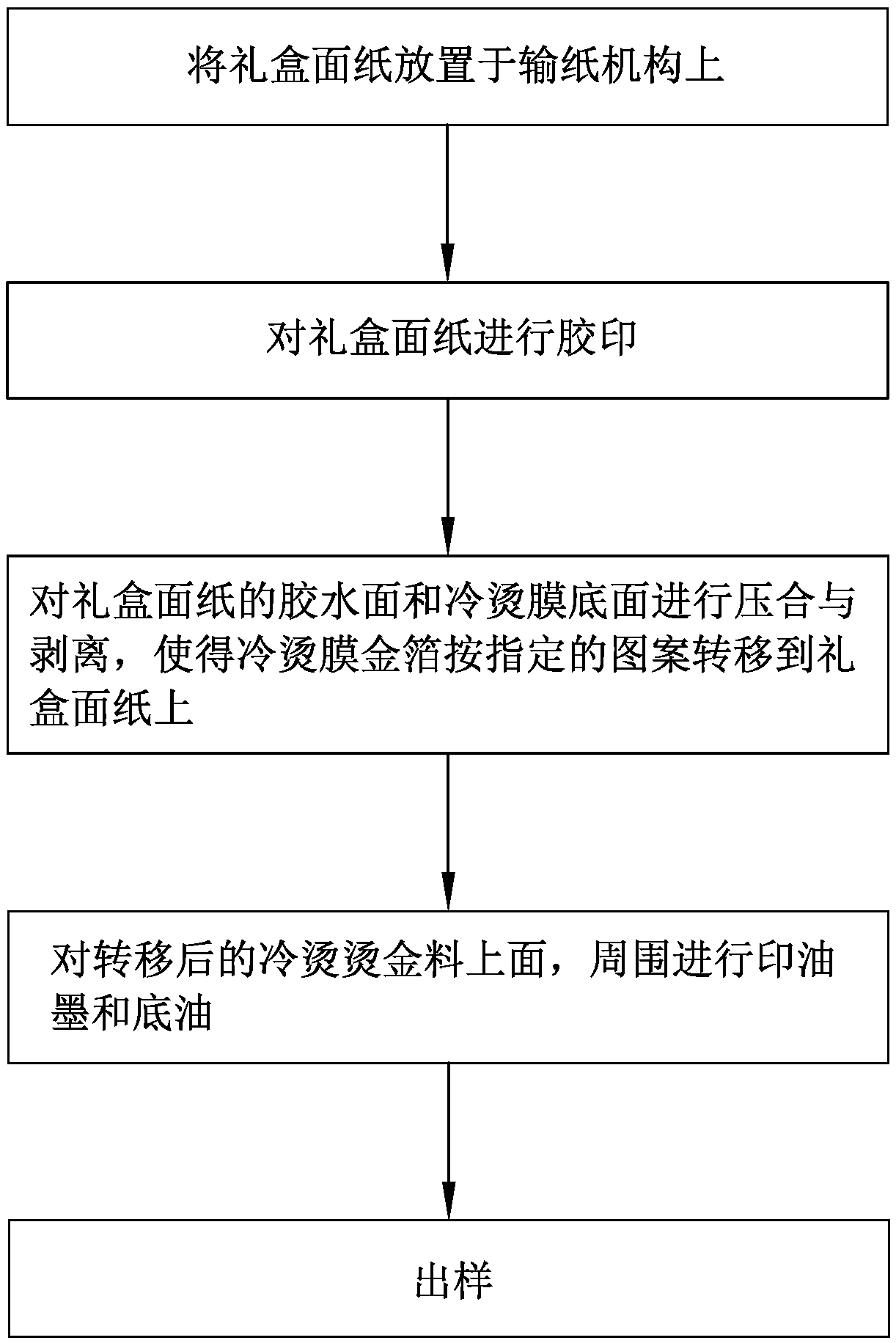

[0027] Such as Figure 1 to Figure 2 The specific embodiment shown is a cold ironing device for gift box packaging, which includes a paper feeding mechanism 10, a printing glue mechanism 20, a cold foil transfer mechanism 30, a printing ink mechanism 40, and a delivery mechanism 50 connected in sequence; the paper feeding mechanism 10 passes through The conveyor belt 60 is connected with the printing glue mechanism 20, and the printing glue mechanism 20, the cold foil transfer mechanism 30, the printing ink mechanism 40, and the delivery mechanism 50 are all connected by rolling.

[0028] Among them, the cold ironing device realizes in-line printing, greatly increases production capacity, reduces manpower, and saves costs.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com